Automotive interior fabric

A technology for fabrics and interiors, applied in the field of automotive interior fabrics, can solve the problems of single variety and function, and achieve good antibacterial effect, long-lasting slow-release aroma, and comfortable hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

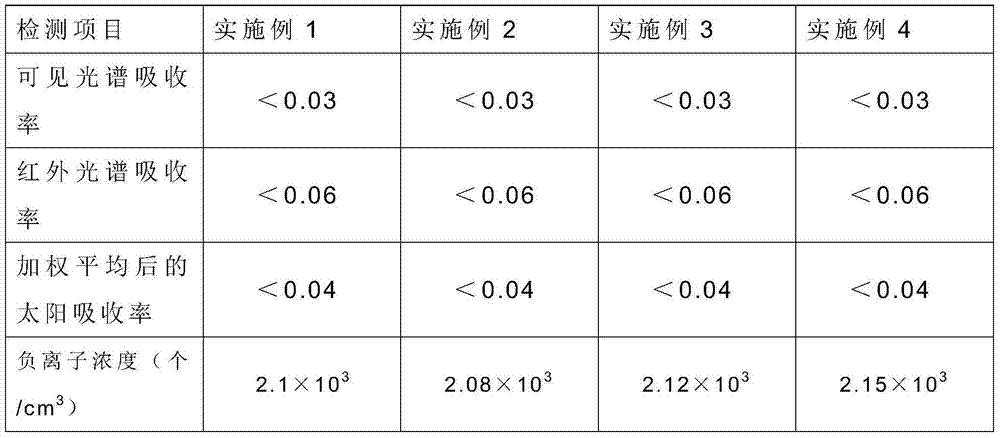

Examples

Embodiment 1

[0018] A kind of automotive interior fabric, comprising two base layers and a sound-absorbing layer bonded between the two base layers, the preparation steps of the base layer are as follows:

[0019] Step (1), blending aramid fibers and bamboo fibers to make warp threads, then blending seaweed charcoal fibers and silicon carbide fibers to make weft threads, and weaving the warp threads and weft threads to obtain the basic fabric;

[0020] Step (2), in parts by weight, 2 parts of lemon essential oil, 11 parts of polyethylene glycol octylphenyl ether, 5 parts of bistallow ethyl ethyl hydroxyethyl methyl ammonium methyl sulfate, 6 parts Isooctyl palmitate, 5 parts of glyceryl citrate stearate, 6 parts of 2,4,4'-trichloro-2'-hydroxydiphenyl ether, 0.5 parts of layered crystalline sodium disilicate were added to 250 parts Heat and stir in deionized water until it is completely dissolved. After cooling down to room temperature, add 600 parts of deionized water to it, and then use c...

Embodiment 2

[0028] A kind of automotive interior fabric, comprising two base layers and a sound-absorbing layer bonded between the two base layers, the preparation steps of the base layer are as follows:

[0029] Step (1), blending aramid fibers and bamboo fibers to make warp threads, then blending seaweed charcoal fibers and silicon carbide fibers to make weft threads, and weaving the warp threads and weft threads to obtain the basic fabric;

[0030] Step (2), according to parts by weight, 3 parts of lemon essential oils, 14 parts of polyethylene glycol octyl phenyl ethers, 8 parts of bistallow ethyl ethyl hydroxyethyl methyl ammonium methyl sulfate, 9 parts Isooctyl palmitate, 8 parts of glyceryl citrate stearate, 9 parts of 2,4,4'-trichloro-2'-hydroxydiphenyl ether, 2 parts of layered crystalline sodium disilicate were added to 300 parts Heat and stir in deionized water until it is completely dissolved. After cooling down to room temperature, add 800 parts of deionized water to it, the...

Embodiment 3

[0038] A kind of automotive interior fabric, comprising two base layers and a sound-absorbing layer bonded between the two base layers, the preparation steps of the base layer are as follows:

[0039] Step (1), blending aramid fibers and bamboo fibers to make warp threads, then blending seaweed charcoal fibers and silicon carbide fibers to make weft threads, and weaving the warp threads and weft threads to obtain a basic fabric;

[0040] Step (2), according to parts by weight, 2.4 parts of lemon essential oils, 12 parts of polyethylene glycol octyl phenyl ethers, 6 parts of bistallow ethyl ethyl hydroxyethyl methyl ammonium methyl sulfate, 8 parts Isooctyl palmitate, 7 parts of glyceryl citrate stearate, 8 parts of 2,4,4'-trichloro-2'-hydroxydiphenyl ether, 1 part of layered crystalline sodium disilicate were added to 270 parts Heat and stir in deionized water until it is completely dissolved. After cooling down to room temperature, add 680 parts of deionized water to it, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com