Production method of high-purity metformin hydrochloride

A high-purity metformin hydrochloride technology, applied in the field of chemistry, can solve the problems of low yield, difficulty in reaching medical standards, and inability to guarantee purity, and achieves the effects of good product quality, low cost, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

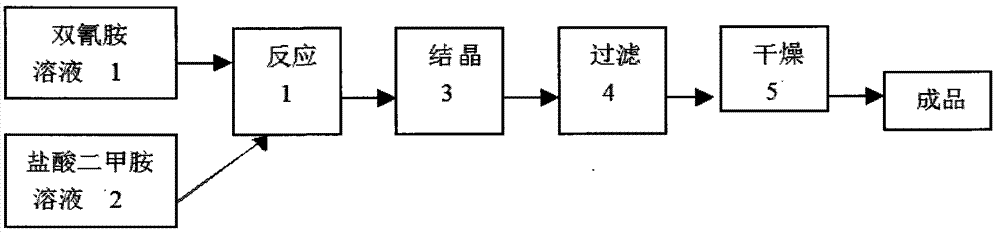

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Put 1000 kg of cyclohexanol into the first 3000L jacketed enamel kettle 1, and feed steam to 75-90°C under stirring. Add 200 kg of solid dicyandiamide under stirring, keep the temperature and stir until completely dissolved.

[0036] In the second jacketed enamel kettle 2 of 2000L, put 800 kg of cyclohexanol into it, and feed steam to 75-90°C under stirring. Add 200 kg of solid dimethylamine hydrochloride under stirring, keep the temperature and stir until completely dissolved.

[0037] Step 2: Slowly add the materials in the second jacketed enamel kettle 2 to the first jacketed enamel kettle 1 for about 1.5 hours, and keep the temperature in the jacketed enamel kettle at 75-90 ℃. After the dropwise addition was completed, the insulation reaction was continued for 0.5 hour.

[0038] Step 3: Move the reaction material obtained in step 2 to the cleaner 3 with a rubber jacket, pass cooling water into the jacket, and continuously stir and cool down. When the temp...

Embodiment 2

[0042] Step 1: Put 1000 kg of the mother liquor of Example 1 into the first 3000L jacketed enamel kettle 1, and feed steam to 75-90°C under stirring. Add 168 kg of solid dicyandiamide under stirring, keep the temperature and stir until completely dissolved.

[0043] In the second jacketed enamel kettle 2 of 2000L, 800 kg of the mother liquor of Example 1 was dropped into, and steam was introduced to 75-90° C. under stirring. Add 163 kg of solid dimethylamine hydrochloride under stirring, keep the temperature and stir until completely dissolved.

[0044] Step 2: Slowly add the material in the second jacketed enamel kettle 2 to the first jacketed enamel kettle 1 for about 1.5 hours, and keep the temperature in the first jacketed enamel kettle 1 75~90℃. After the dropwise addition was completed, the insulation reaction was continued for 0.5 hour.

[0045] Step 3: Move the reaction material obtained in Step 2 to a crystallizer with a rubber jacket, pour cooling water into the j...

Embodiment 3

[0049] Put the mother liquor of Example 2 into the first jacketed enamel kettle 1, add 10 kg of activated carbon, heat and stir at 90°C, filter, then use it as a solvent, and repeat the operation of Example 2 to obtain metformin hydrochloride Weighing, 303.2 grams, yield 91.6%, sampling analysis, melting point 224.1 ~ 225.2 ° C, in line with medical standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com