Method for preparing 2-chlorine-5 chloromethyl thiazole

A technology of chloromethylthiazole and chloromethylthiazole hydrochloride, which is applied in the field of preparation of 2-chloro-5-chloromethylthiazole, can solve problems such as low product yield, air pollution, and difficulty, and achieve The effect of shortening the reaction path, simplifying the experimental operation and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

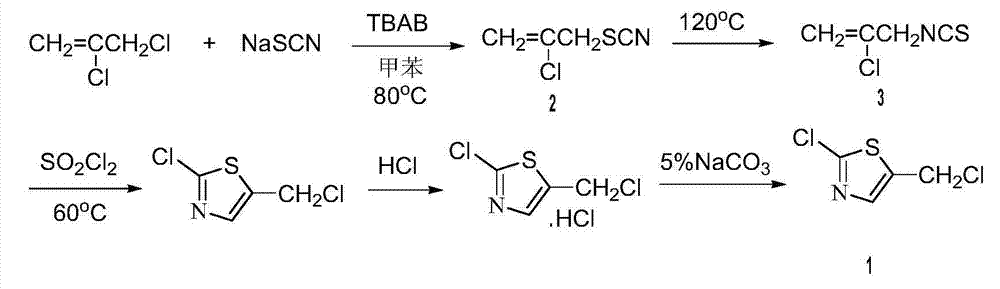

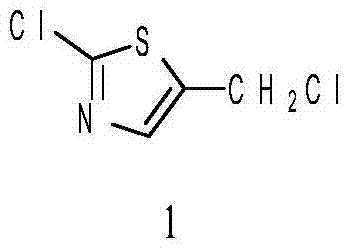

[0029] The invention provides the preparation method of 2-chloro-5-chloromethylthiazole, comprising the following steps:

[0030] (a) Sodium thiocyanate and 2,3-dichloropropene are mixed in a solvent to obtain 1-thiocyano-2-chloropropene (2).

[0031] (b) subjecting (2) obtained in (a) above to high-temperature isomerization to generate 1-isothiocyanato-2-chloropropene (3).

[0032] (c) The (3) obtained in the above (b) is mixed with sulfuryl chloride in a solvent to obtain the compound 2-chloro-5-chloromethylthiazole.

[0033] (d) Purifying and purifying the 2-chloro-5-chloromethylthiazole produced in (c) above.

[0034]

Embodiment 1

[0037] Step 1. Substitution-isomerization reaction

[0038] Add 100g of sodium thiocyanate (1.23mol), 2.5g of tetrabutylammonium bromide, and 200mL of toluene into a 500mL three-necked flask, and slowly add 108g (0.97mol) of 2,3-dichloropropene dropwise under stirring. . Connect the condenser tube, condense and reflux in an 80°C oil bath for 4 hours, then directly heat up to 120°C for 3 hours (experimental phenomenon: from the original yellow liquid and white solid to dark brown liquid, after high temperature isomerization, it turns into black opaque liquid). After the reaction was completed and cooled, the solvent toluene was evaporated on a rotary evaporator to obtain 117.5 g of a black opaque product. The product and distilled toluene were analyzed by gas chromatography (gas phase conditions: 55°C for 2min, rising to 250°C at a rate of 20°C per minute), the product purity was 93%, and the yield was 81.3%. The distilled toluene contained about 9% of the product.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com