A white light emitting aluminum nitride material injected with rare earth elements, preparation method and application

A technology of rare earth elements and aluminum nitride, which is applied in the field of preparing white light-emitting AlN materials by ion implantation, can solve the problems of not being able to achieve white light emission, and achieve the effect of white light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

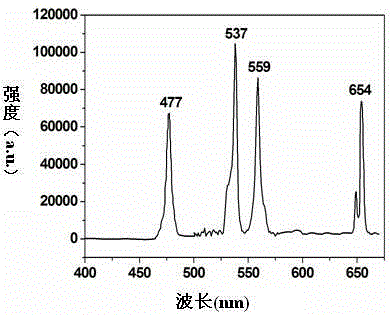

Embodiment 1

[0018] In this embodiment, the injection doses of Pr, Er, and Tm are all 10 14 piece / cm 2 . The thickness of the AlN thin film is 2 microns, which is prepared on the sapphire substrate by MOCVD method. Put the AlN thin film material into an ion implantation device for Pr ion implantation, the implantation conditions are: implantation energy 200KeV, implantation angle 0 0 , with an injection dose of 10 14 pieces / square centimeter. Then the Pr-implanted AlN thin film material is taken out for annealing treatment. The annealing conditions include: normal pressure N 2 Flowing atmosphere, the flow rate is 0.6 sccm, the annealing temperature is 900°C, and the annealing time is 2 hours. Put the annealed Pr-implanted AlN thin film material into the ion implantation device for Er ion implantation. The implantation conditions are: the implantation energy range is 200KeV, and the implantation angle is 0 0 , the implantation dose of Er and the implantation dose of Pr ions keep the s...

Embodiment 2

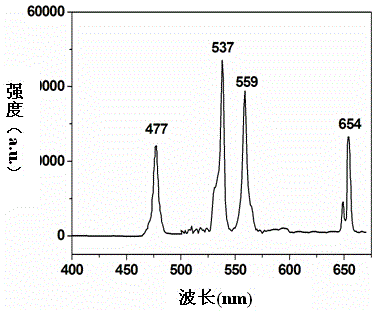

[0021] In this embodiment, the injection doses of Pr, Er, and Tm are all 10 15 piece / cm 2 . The thickness of the AlN thin film is 2 microns, which is prepared on the sapphire substrate by MOCVD method. Put the AlN thin film material into an ion implantation device for Pr ion implantation, the implantation conditions are: implantation energy 300KeV, implantation angle 6 0 , with an injection dose of 10 15 pieces / square centimeter. Then the Pr-implanted AlN thin film material is taken out for annealing treatment. The annealing conditions include: normal pressure N 2 Flowing atmosphere, the flow rate is 0.8 sccm, the annealing temperature is 1000°C, and the annealing time is 3 hours. Put the annealed Pr-implanted AlN thin film material into the ion implantation device for Er ion implantation. The implantation conditions are: the implantation energy range is 300KeV, and the implantation angle is 6 0 , the implantation dose of Er and the implantation dose of Pr ions keep the ...

Embodiment 3

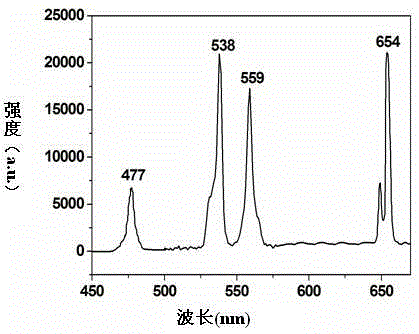

[0024] In this embodiment, the injection doses of Pr, Er, and Tm are all 10 16 piece / cm 2 . The thickness of the AlN thin film is 2 microns, which is prepared on the sapphire substrate by MOCVD method. Put the AlN thin film material into an ion implantation device for Pr ion implantation, the implantation conditions are: implantation energy 400KeV, implantation angle 10 0 , with an injection dose of 10 16 pieces / square centimeter. Then the Pr-implanted AlN thin film material is taken out for annealing treatment. The annealing conditions include: normal pressure N 2 Flowing atmosphere, the flow rate is 1.0 sccm, the annealing temperature is 1050°C, and the annealing time is 4 hours. Put the annealed Pr-implanted AlN film material into the ion implantation device for Er ion implantation. The implantation conditions are: the implantation energy range is 400KeV, and the implantation angle is 10 0 , the implantation dose of Er and the implantation dose of Pr ions keep the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com