Efficient intermittent rice-bran-oil degumming technology

A technology of rice bran oil and rice bran crude oil, which is applied in the direction of edible oil/fat, fat oil/fat refining, fat production, etc., and can solve problems such as difficult removal, color change of rice bran oil, and difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

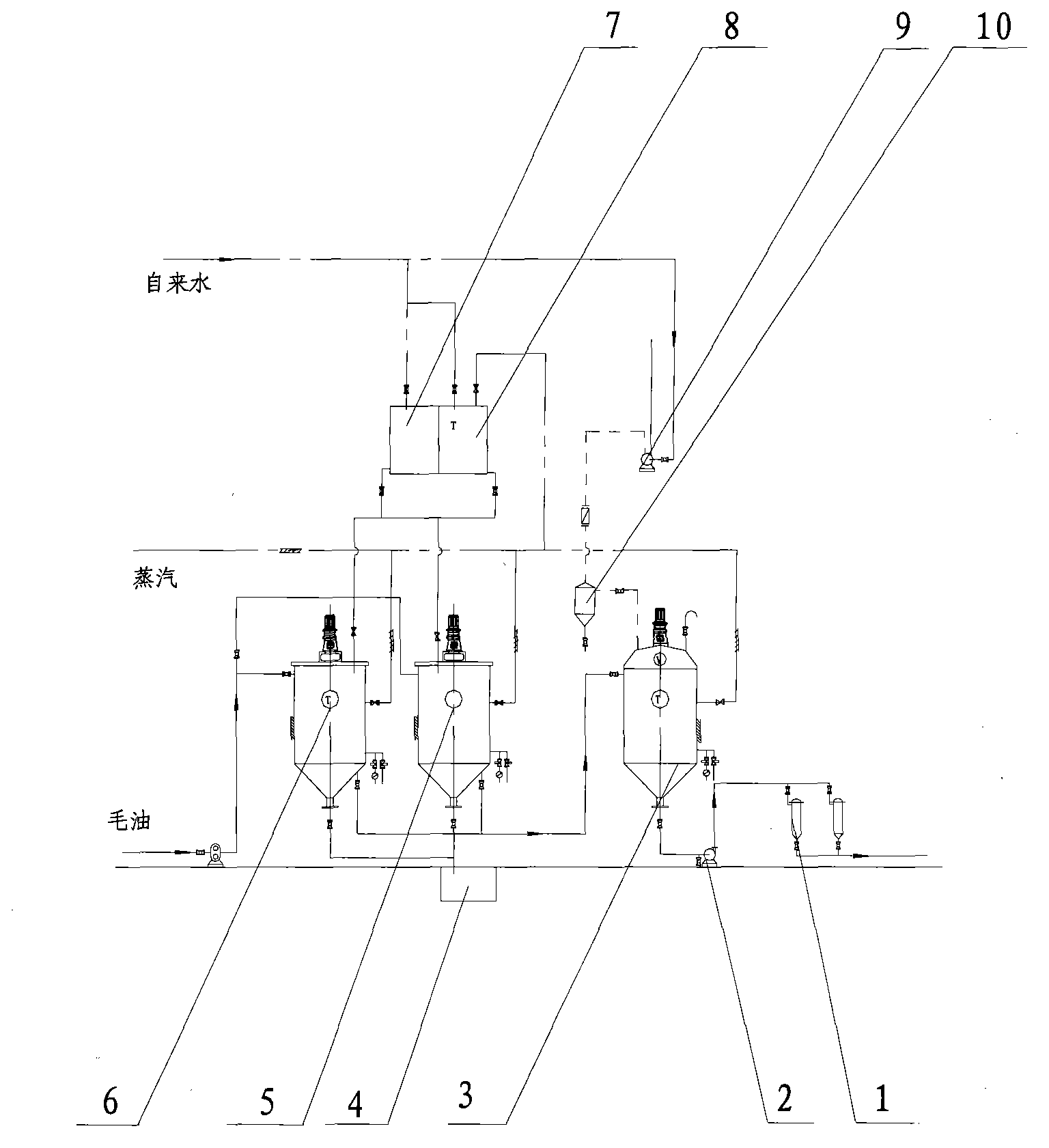

Image

Examples

Embodiment Construction

[0007] The specific process of the process of the present invention is that the crude rice bran oil is input into No. 1 refining pot 6 through an oil pump; after the crude oil is heated to about 80°C, phosphoric acid with a concentration of 85% is added in proportion to stir, so that the non-hydrating The phospholipids are converted into hydrated phospholipids; after stirring for a period of time, open the outlet valve of the hot water tank 8 and add hot water in proportion to make the phospholipids in the crude rice bran oil absorb water and then flocculate into agglomerates. After the crude oil is hydrated once, add 0.5% alum and hot water in proportion to the alum tank 7, and then input it into the No. 1 refining pot 6, so that the phospholipids in the rice bran crude oil absorb water and ionize to produce Al3+, and then flocculate again to form group; due to the effect of alum solution, its coagulation force is extremely strong, which can absorb other pigment impurities; at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com