A kind of anti-delamination, decolorization permeable brick and preparation method thereof

A permeable brick and anti-stripping technology, applied in the field of environmental protection, can solve the problems of difficult balance of water seepage, moisturizing and compressive strength, easy delamination, poor service life, etc. The effect of delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing the above-mentioned permeable brick, which includes:

[0034] Mix the raw materials of the bottom layer, set aside, mix the raw materials of the water-permeable layer, set aside, mix the raw materials of the surface layer, set aside, pass the mixed raw materials of the bottom layer, the raw materials of the water-permeable layer and the raw materials of the surface layer through the existing equipment and method It can be pressed into shape and maintained by existing methods.

[0035] Preferably, when mixing the raw materials of the surface layer, first mix the cement, glass slag, the first ceramic waste, crushed stone, and half of the water for 30 seconds, then add the thickener, epoxy resin and water glass and stir for 60 seconds, then add the remaining Water, stirring for 120s, can effectively improve the effect of anti-bleaching.

Embodiment 1

[0038] The invention relates to a detachment-proof and decolorization permeable brick, which is made by mixing the raw materials of the bottom layer, mixing the raw materials of the permeable layer, mixing the raw materials of the surface layer, and pressing and forming.

[0039] Among them, the raw materials of the surface layer are mixed by first mixing cement, glass slag, the first ceramic waste, gravel, and half of the water for 30 seconds, then adding thickener, epoxy resin and water glass and stirring for 60 seconds, then adding the remaining water. Stir for 120s.

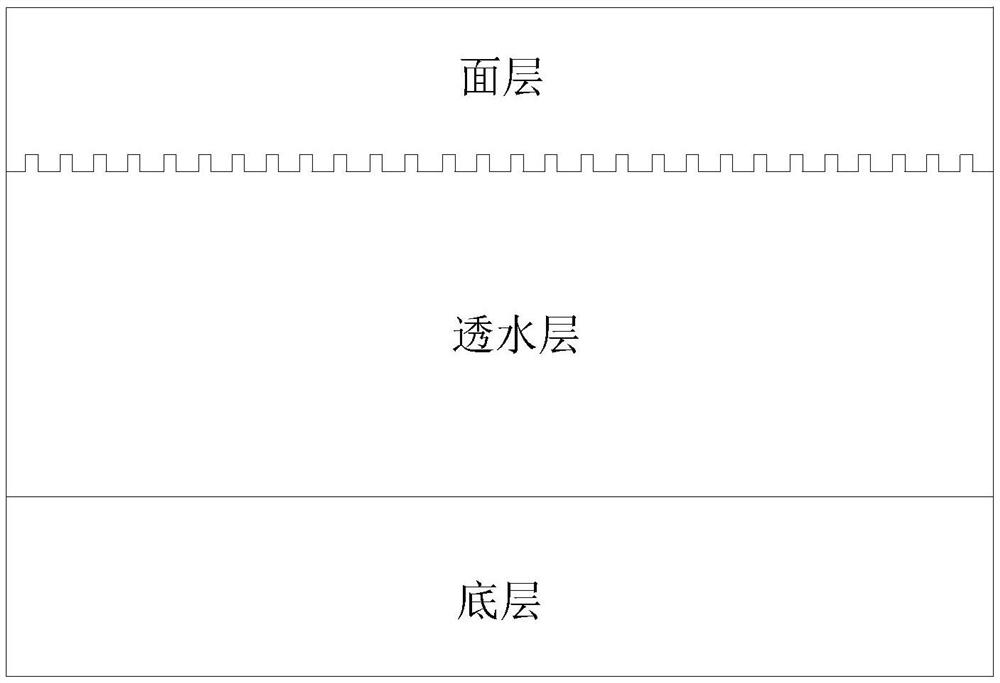

[0040] Wherein, the surface layer, the water-permeable layer and the bottom layer are connected sequentially, the surface layer is connected with the water-permeable layer, the side of the water-permeable layer close to the surface layer has a plurality of protrusions, the water-permeable layer is provided with honeycomb-shaped first through holes, and the first through holes The two ends are respectively con...

Embodiment 2

[0046] The invention relates to a detachment-proof and decolorization permeable brick, which is made by mixing the raw materials of the bottom layer, mixing the raw materials of the permeable layer, mixing the raw materials of the surface layer, and pressing and forming.

[0047] Among them, the raw materials of the surface layer are mixed by first mixing cement, glass slag, the first ceramic waste, gravel, and half of the water for 30 seconds, then adding thickener, epoxy resin and water glass and stirring for 60 seconds, then adding the remaining water. Stir for 120s.

[0048] Wherein, the surface layer, the water-permeable layer and the bottom layer are connected sequentially, the surface layer is connected with the water-permeable layer, the side of the water-permeable layer close to the surface layer has a plurality of protrusions, the water-permeable layer is provided with honeycomb-shaped first through holes, and the first through holes The two ends are respectively con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com