Quantitative determination method for fiber content of viloft fiber and polyester fiber blended textiles

A quantitative detection method and polyester fiber technology, which can be applied in the direction of removing certain components and weighing, etc., can solve the problems of affecting the accuracy of measurement results, measurement efficiency, low detection efficiency, etc., so as to improve detection efficiency and shorten detection time. , The effect of strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

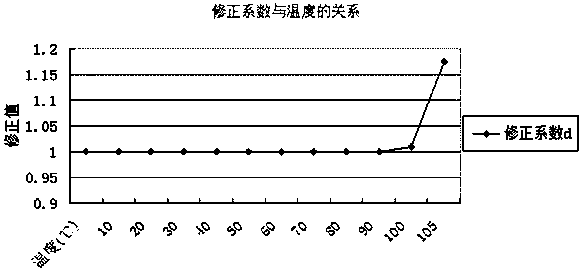

[0019] Embodiment 1 polyester fiber correction factor test

[0020] Take a certain quality of polyester fiber and place it in a constant temperature oven at 105°C for 3 hours. After it is fully dried, take it out quickly and place it in a desiccator to cool to room temperature. Weigh the polyester fiber with a balance with an accuracy of 0.1mg. The weight of the fiber, denoted as a, according to the blended product (g): reagent (mL) = 1:100 bath ratio, the polyester fiber is placed in sulfuric acid with a mass concentration of 70% to 80%, and it is continuously mixed at 40 to 110°C. After shaking for 60 minutes, wash the polyester fiber with water until neutral, dry it in a constant temperature oven at 105°C, then quickly take it out and place it in a desiccator to cool to room temperature, and weigh b with a balance with an accuracy of 0.1mg. By comparing the size of a and b, the mass loss of polyester fiber after treatment with sulfuric acid reagent can be obtained, and d=a / ...

Embodiment 2

[0025] The dissolution test of embodiment 2viloft fiber

[0026] In this experiment, 70% sulfuric acid, 75% sulfuric acid, and 80% sulfuric acid were selected as the dissolving reagents. A certain mass of viloft fibers were put into the above reagents respectively. ℃, 90℃, 100℃ conditions, according to Table 2, it can be seen that viloft fiber has good solubility in 70%-80% sulfuric acid reagent, and its dissolution time is rapid with the increase of temperature It becomes shorter and dissolves immediately when the temperature exceeds 100°C.

[0027] Table 2 viloff fiber dissolving performance test

[0028] category 20℃ 50℃ 70℃ 80℃ 90℃ 100℃ 70% sulfuric acid partially dissolved partially dissolved basically dissolved completely dissolved fast dissolve Dissolve immediately 75% sulfuric acid partially dissolved partially dissolved basically dissolved completely dissolved fast dissolve Dissolve immediately 80% sulfuric acid ...

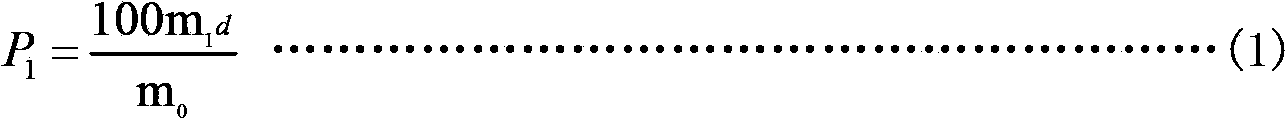

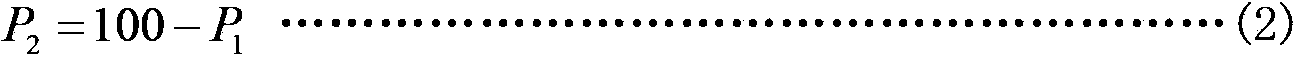

Embodiment 340

[0029] Dissolution test at the time of embodiment 340 ℃

[0030] Take a certain amount of blended products of viloft fiber and polyester fiber whose component content is unknown, and place it in a constant temperature oven at 105°C for 3 hours. After fully drying, take it out quickly and place it in a desiccator to cool to room temperature. Weigh the weight of the blended product with a balance with an accuracy of 0.1 mg, and record it as m 0 , according to blended product (g): reagent (mL)=l: 100 bath ratio will blended product be placed in mass concentration and be 75% sulfuric acid, here, described blended product is by mass, and reagent is by volume. After continuous shaking at 40°C for 60 minutes, the viloft fibers are completely dissolved in sulfuric acid solution, and the insoluble fibers, namely polyester fibers, are washed with water until neutral, dried in a constant temperature oven at 105°C, and then quickly taken out and placed in a desiccator Cool down to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com