High-PFC constant current control device without loop compensation and voltage converter

A technology of constant current control and loop compensation, applied in the direction of high-efficiency power electronic conversion, output power conversion device, conversion of DC power input to DC power output, etc. Low problems, to achieve the effect of saving cost and space, system stability, and reducing peripheral components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

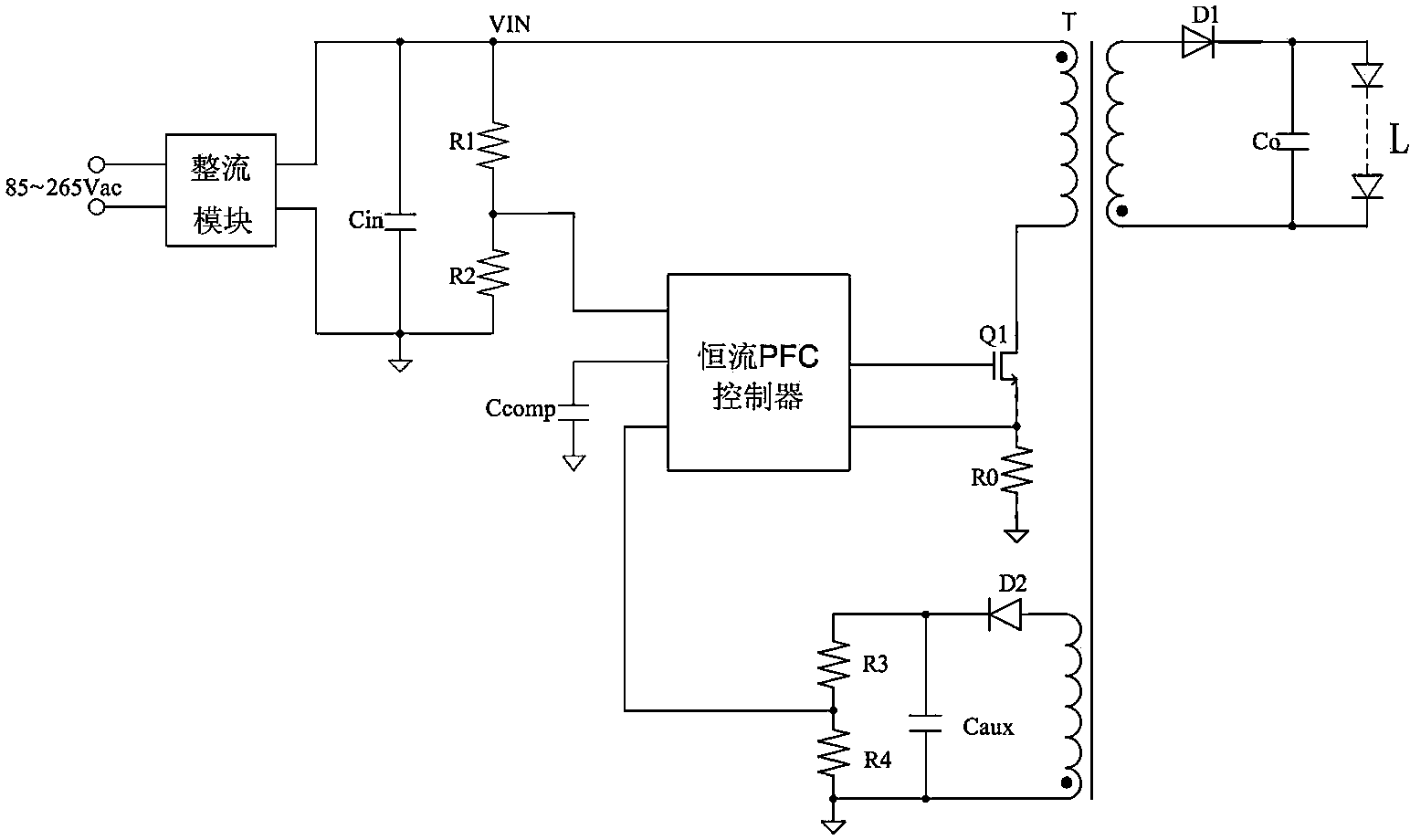

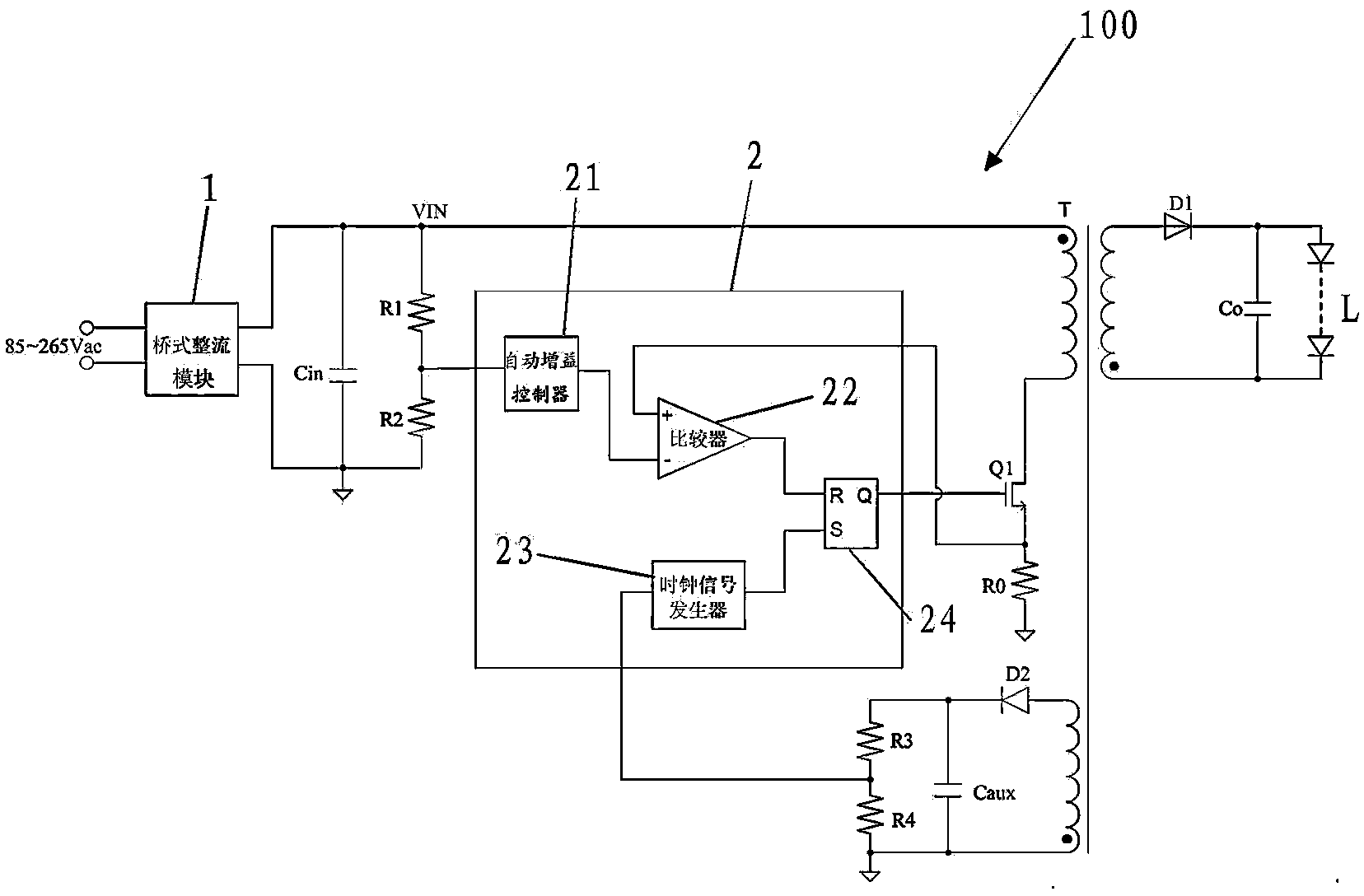

[0039] like figure 2 As shown, it is a schematic diagram of the application of a high PFC constant current control device 2 without loop compensation in the flyback converter 100 according to the present invention. The flyback converter 100 includes a bridge rectifier module 1, an input capacitor Cin, transformer T, power switch tube Q1, primary current sense resistor R0, primary voltage sampling resistor network R1, R2, secondary rectifier diode D1, output capacitor Cout, output LED load, auxiliary winding side rectifier diode D2, auxiliary winding Voltage sampling network R3, R4, Caux.

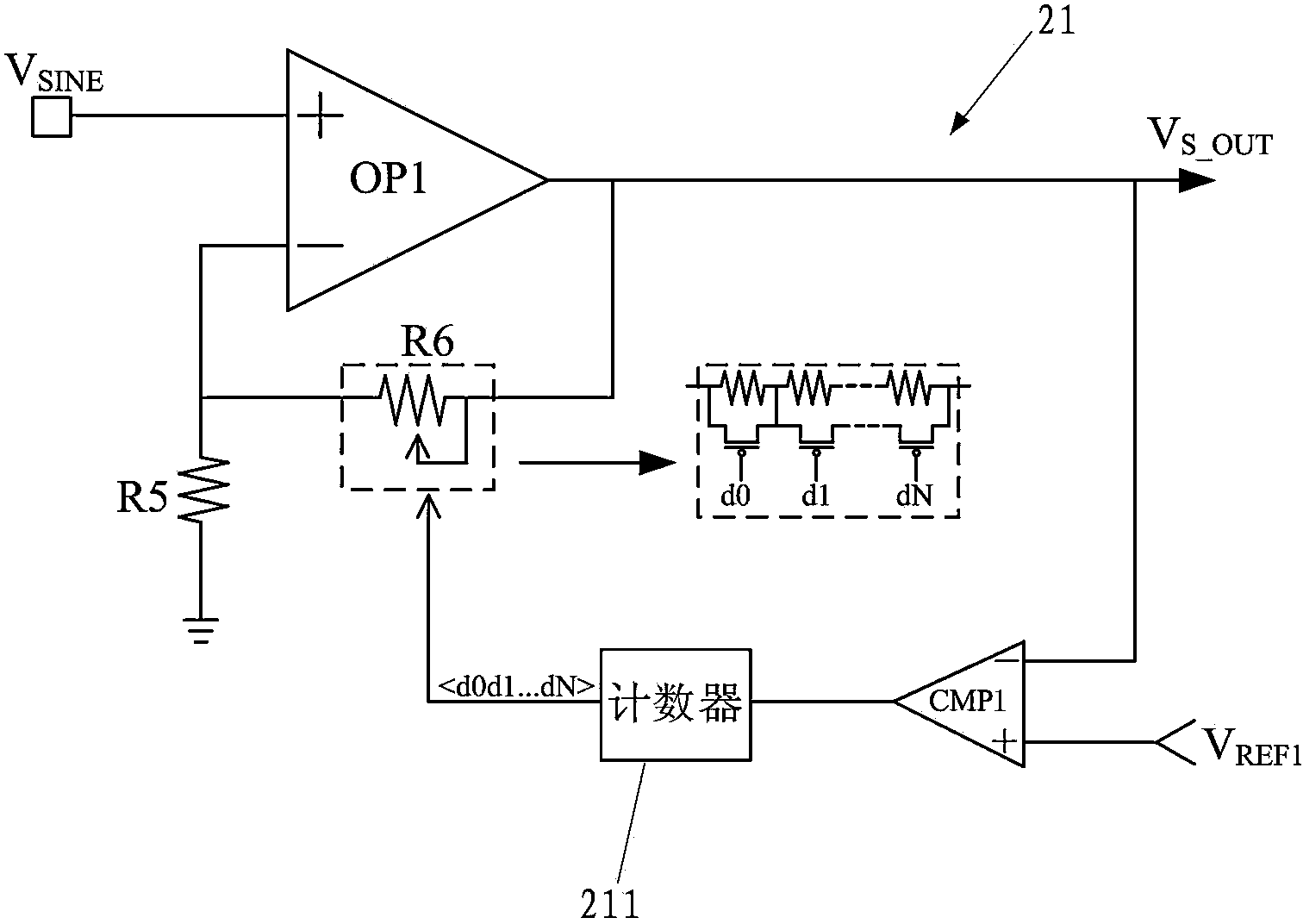

[0040] The high PFC constant current control device 2 without loop compensation involved in the present invention includes an automatic gain controller 21 , a peak current control comparator 22 , a clock signal generator 23 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com