Additive-containing single-crystal-state potassium nitrate glass-reinforcing molten salt and glass reinforcing technology

A technology of glass strengthening and potassium nitrate, which is applied in glass tempering, glass production, glass manufacturing equipment, etc. It can solve the problems of not accurately giving polycrystalline components to determine the crystal state, complex additive components, and difficult operations. Achieve the effect of improving product quality, simple components, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

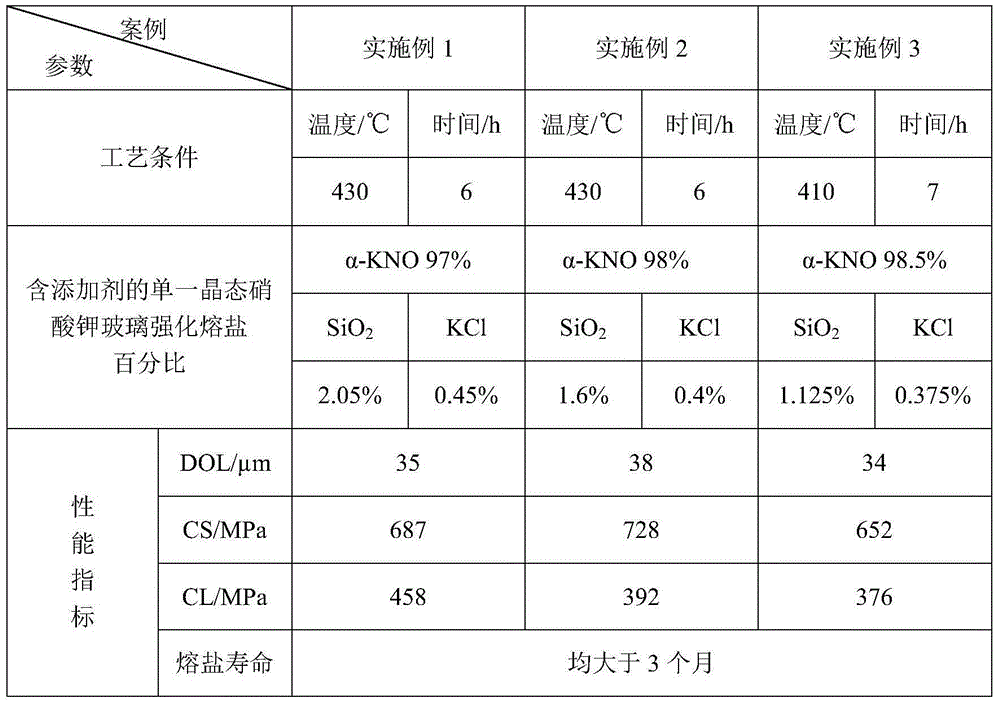

Embodiment 1

[0034] Soda-lime-silica glass is processed into thin slices of 350mm*40mm*3mm.

[0035] Use alcohol and acetone to wipe the dust and oil on the glass surface (or ultrasonic cleaning) respectively, and put the processed glass sheet into a drying oven for drying.

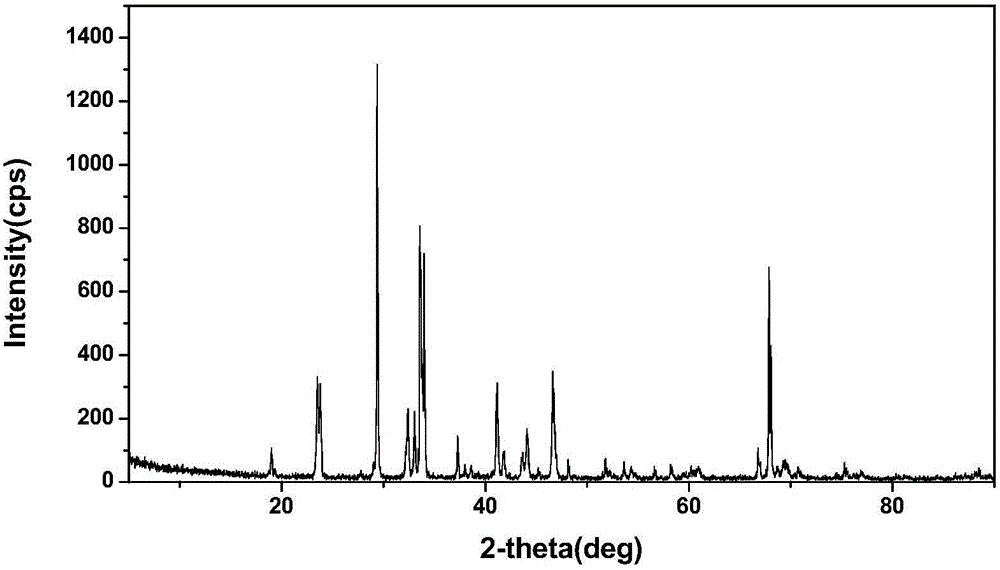

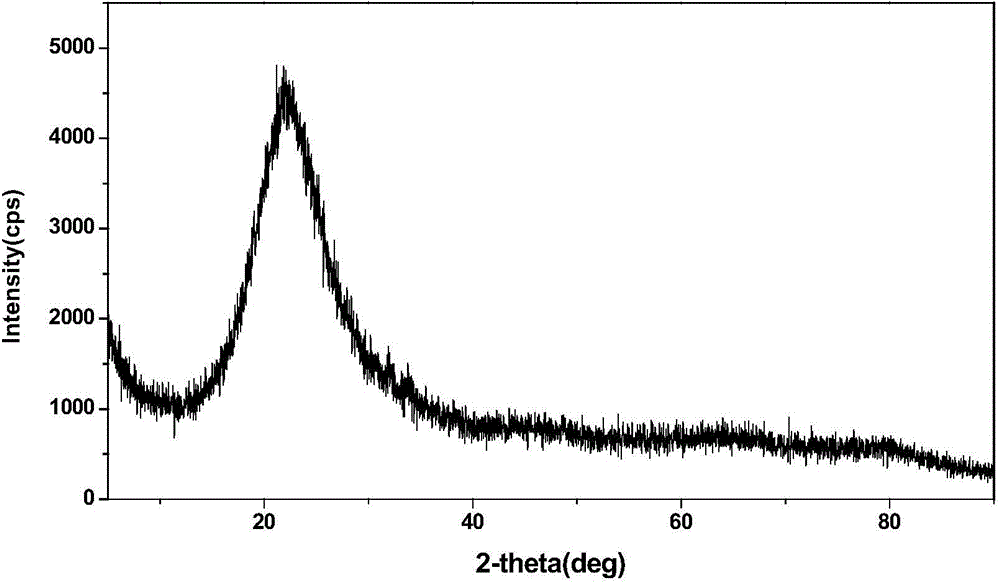

[0036] Formulation of single crystalline potassium nitrate glass-strengthening molten salt with additive, α-KNO 3 97%, silicon dioxide 2.05%, KCl 0.45%.

[0037] The cleaned and dried glass flakes were preheated in a muffle furnace for 45 minutes at a constant temperature of 350°C.

[0038] Grind the prepared single-crystal potassium nitrate glass-strengthening molten salt containing additives to fineness and preheat for 50 minutes at a constant temperature of 340°C.

[0039] Submerge the preheated glass flakes into the preheated single crystalline potassium nitrate glass-strengthening molten salt containing additives, and rapidly raise the furnace temperature to 430°C, and conduct constant temperature treatment for...

Embodiment 2

[0042] Soda-lime-silica glass is processed into thin slices of 350mm*40mm*3mm.

[0043] Use alcohol and acetone to wipe the dust and oil on the glass surface (or ultrasonic cleaning) respectively, and put the processed glass sheet into a drying oven for drying;

[0044] Formulation of single crystalline potassium nitrate glass-strengthening molten salt with additive, α-KNO 3 98%, silicon dioxide 1.6%, KCl 0.4%.

[0045] The cleaned and dried glass flakes were preheated in a muffle furnace for 55 minutes at a constant temperature of 350°C.

[0046] Grind the prepared single-crystal potassium nitrate glass-strengthening molten salt containing additives to fineness and preheat for 50 minutes at a constant temperature of 340°C.

[0047] Submerge the preheated glass flakes into the preheated single crystalline potassium nitrate glass-strengthening molten salt containing additives, and rapidly raise the furnace temperature to 430°C, and conduct constant temperature treatment for 6...

Embodiment 3

[0050] Soda-lime-silica glass is processed into thin slices of 350mm*40mm*3mm.

[0051] Use alcohol and acetone to wipe the dust and oil on the glass surface (or ultrasonic cleaning) respectively, and put the processed glass sheet into a drying oven for drying.

[0052] Formulation of single crystalline potassium nitrate glass-strengthening molten salt with additive, α-KNO 3 98.5%, silicon dioxide 1.125%, KCl 0.375%.

[0053] The cleaned and dried glass flakes were preheated in a muffle furnace for 50 minutes at a constant temperature of 350°C.

[0054] Grind the prepared additive-containing single crystal potassium nitrate glass-strengthening molten salt and preheat it for 60 minutes at a constant temperature of 340°C.

[0055] Submerge the preheated glass flakes into the preheated single crystalline potassium nitrate glass-strengthening molten salt containing additives, rapidly raise the furnace temperature to 410°C, and conduct constant temperature treatment for 7 hours t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com