Wet-mix mortar admixture and its preparation method and application

A wet-mixed mortar and admixture technology, applied in the field of construction mortar, can solve the problems of poor water retention, unsatisfactory operability of mortar, fugitive dust, etc., to increase compressive strength and bond strength, improve workability and water retention rate , Good material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

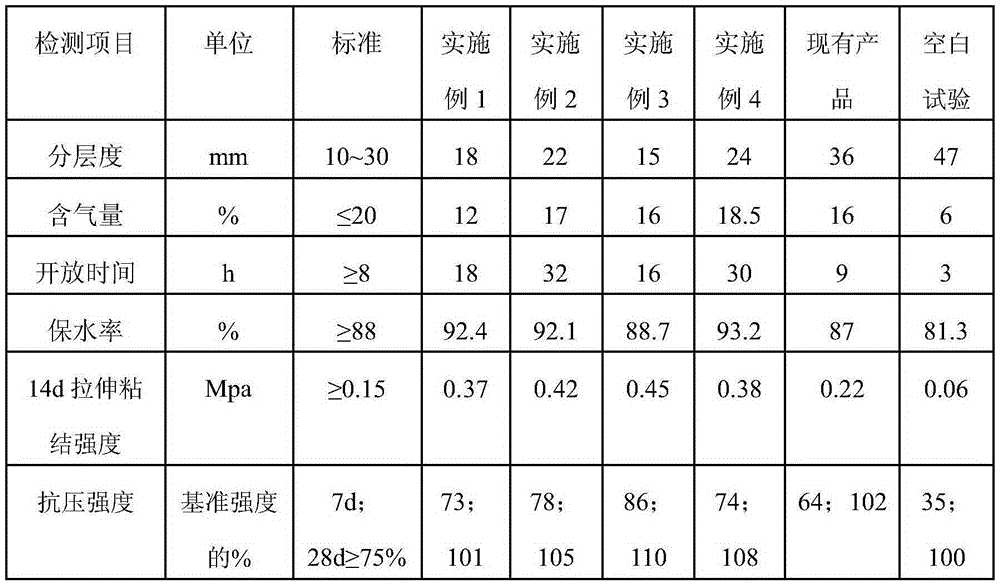

Examples

preparation example Construction

[0028] The preparation method of the wet-mixed mortar admixture of the present invention is as follows: Weigh an appropriate amount of water according to the weight percentage, add the retarder, the water-retaining agent, and the reinforcing agent in sequence according to the weight percentage, start stirring to mix the materials evenly, and then slowly add the air-entraining agent and Anti-cracking agent, and fully stirred to prepare material A; weigh an appropriate amount of water according to weight percentage, add water reducing agent and shrinkage reducing agent in sequence according to weight percentage, and stir evenly to prepare material B.

[0029] The invention also provides the application of the wet-mix mortar admixture of the invention in wet-mix mortar. The wet-mix mortar admixture of the present invention is preferably added to the wet-mix mortar in a double-mixing manner, that is, material A and material B are respectively added to the wet-mix mortar. Wherein, ...

Embodiment 1

[0045]Take 95.1g of water, add 2.5g of retarder, 0.5g of water-retaining agent, and 1.0g of reinforcing agent in order to start stirring to mix the materials evenly, then slowly add 0.8g of air-entraining agent and 0.1g of anti-cracking agent, and fully stir to obtain A material.

[0046] Take 96.7g of water, add 3g of water reducing agent and 0.3g of shrinkage reducing agent in sequence, and stir well to obtain material B.

[0047] Wherein, the air-entraining agent is sodium lauryl sulfate; the retarder is sodium gluconate; the anti-cracking agent is hydroxypropyl methylcellulose; the reinforcing agent is triethanolamine; It is maltodextrin; the water reducer is polycarboxylate high-performance polyester water reducer; and the shrinkage reducer is polyethylene glycol.

Embodiment 2

[0049] Take 94.1g of water, add 2.5g of retarder, 0.5g of water retaining agent, and 1.0g of reinforcing agent in order to start stirring to mix the materials evenly, then slowly add 1.8g of air-entraining agent and 0.1g of anti-cracking agent, and fully stir to obtain material A .

[0050] Take 96.7g of water, add 3g of water reducing agent and 0.3g of shrinkage reducing agent in sequence, and stir well to obtain material B.

[0051] Wherein, the air-entraining agent is sodium lauryl sulfate; the retarder is a mixture of sodium pyrophosphate and citric acid, by mass ratio, sodium pyrophosphate: citric acid=1.6:1.0; the anti-cracking agent is hydroxypropyl Methyl cellulose; the strengthening agent is triethanolamine; the water-retaining agent is maltodextrin; the water-reducing agent is polycarboxylate high-performance polyester water-reducer; the anti-cracking agent is polyethylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com