Hydrocolloid dressing and preparation method thereof

A hydrocolloid and hydrocolloid layer technology, applied in bandages, coatings, absorbent pads, etc., can solve the problems of two-layer detachment, air bubbles, insufficient binding force of hydrocolloid dressings, etc., and achieve the effect of reducing process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

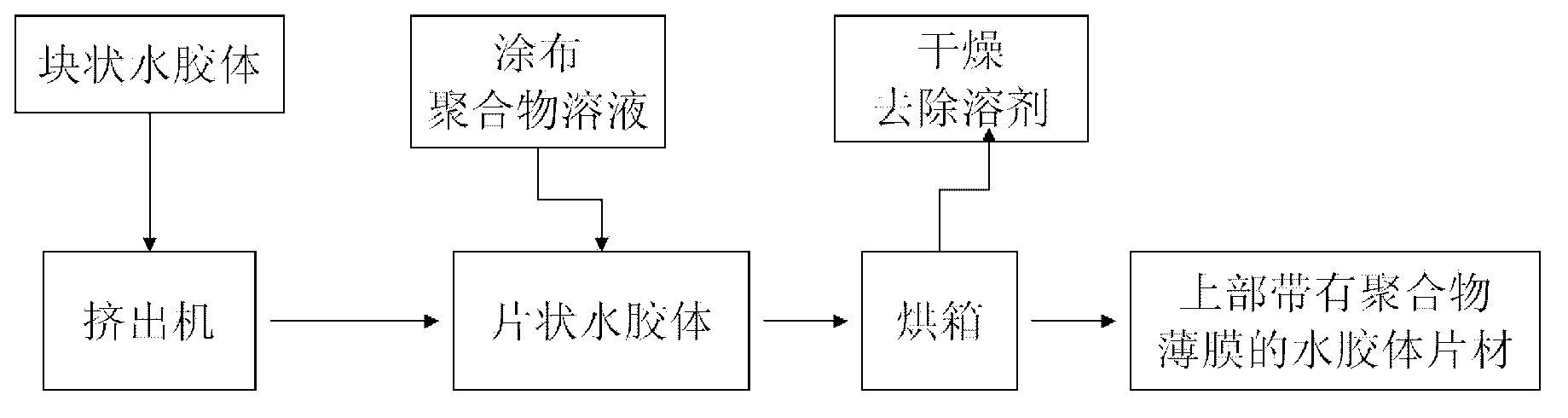

[0073] Based on the total weight of the raw materials used, 35% of BR9000 butadiene rubber purchased from Qilu Petrochemical, 45% of PIB 6H polyisobutylene purchased from RitChem, and 20% of HS100000 YP2 hydroxyethyl cellulose purchased from Clariant Put it into a vacuum kneader for normal kneading for 1-2 hours, and then vacuum (vacuum 0.07MPa) for 1 hour.

[0074] The above mixture was placed in a rubber extruder and extruded into a hydrocolloid sheet with an average thickness of 0.5 mm. The extrusion temperature is 80-120°C.

[0075] Use a solvent-type coater to coat the V-Coat AB5454LV polyurethane solution (solid content: 30%, viscosity: 12,000-18,000cps / 25℃) purchased from Jiaxing Puyou on the above-mentioned hydrocolloid extruded sheet, using a comma Roll, gap (gap) is set to 83 microns. Dry the solvent in an oven with a temperature gradient of 40-200°C. After drying, a polyurethane film with an average thickness of 25 microns is formed on the hydrocolloid layer.

[0076] ...

Embodiment 2

[0078] Based on the total weight of the raw materials used, 50% was purchased from Goodyear's Natsyn2210 polyisoprene, 20% was purchased from Hangzhou Shunda's SDG-8650 polyisobutylene, and 30% was purchased from Suzhou Weiyi's FH5000 carboxymethyl The sodium cellulose is put into a vacuum kneader and kneaded normally for 1-2 hours, and then vacuumed (vacuum degree is 0.05 MPa) for 1 hour.

[0079] The above mixture was placed in a rubber extruder and extruded into a hydrocolloid sheet with an average thickness of 1 mm. The extrusion temperature is 80-120°C.

[0080] The V-Coat AB5858LV polyurethane solution (solid content: 30%, viscosity: 25,000-40,000 cps / 25° C.) purchased from Jiaxing Puyou was coated on the above-mentioned hydrocolloid extruded sheet with a solvent coating machine. Dry the solvent in an oven with a temperature gradient of 40-200°C. After drying, a polyurethane film with an average thickness of 30 microns is formed on the hydrocolloid layer. Cross-link the sa...

Embodiment 3

[0082] Using the same formula and process conditions as in Example 2, a hydrocolloid sheet with an average thickness of 1 mm was prepared.

[0083] The V-Coat775 polyurethane solution (solid content: 30%, viscosity: 85,000-110,000 cps / 25° C.) purchased from Jiaxing Puyou was coated on the above-mentioned hydrocolloid extruded sheet with a solvent coating machine. Dry the solvent in an oven with a temperature gradient of 40-200°C. After drying, a polyurethane film with an average thickness of 30 microns is formed on the hydrocolloid layer. Cross-link the sample with gamma rays, and set the gamma dose to 10-50kGy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com