Defoaming agent for liquid detergent

A technology for liquid detergents and defoaming agents, applied in detergent compounding agents, detergent compositions, liquid degassing and other directions, can solve problems such as poor compatibility and inability to achieve the effect of compounding multiple emulsifiers. , to achieve excellent clarity, excellent stability, good emulsification and dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

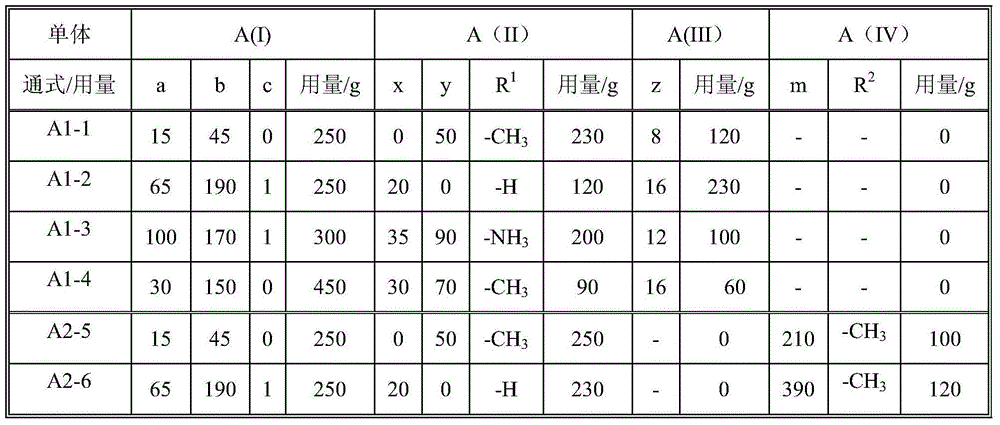

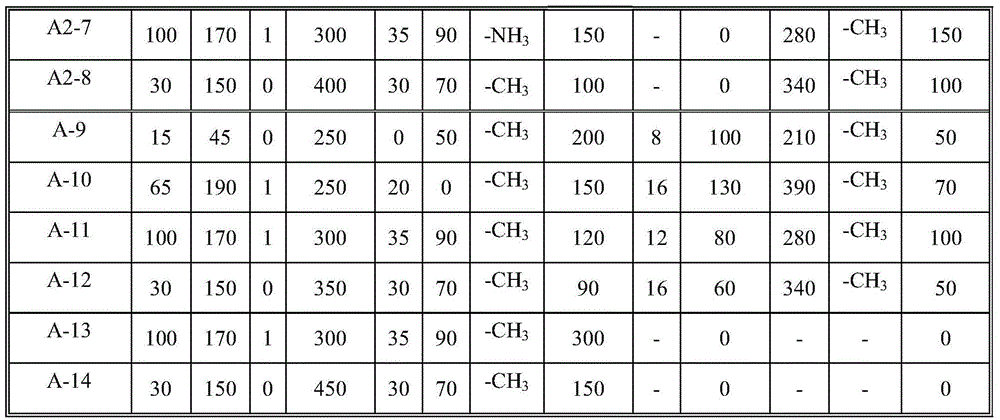

[0091] The preparation method of each modified polysiloxane is to first add the above-mentioned amount of A(I), A(II), A(III) and A(IV) into the reaction vessel, and add the catalyst A(V). React at 80-180°C for 0.5-3 hours to obtain modified polyorganosiloxane. Wherein the catalyst A (V) is an isopropanol solution of chloroplatinic acid with a platinum content of 5-15 ppm. In the preparation of the modified polysiloxane A1-1-4, the reaction temperature is 100-110° C., and the amount of the catalyst is 0.05-0.08% of the mass of the modified polysiloxane. In the preparation of A2-5-8, the reaction temperature is 110-130°C, and the amount of the catalyst is 0.04-0.06% of the mass of the modified polysiloxane. In the preparation of A-9-A-12, the reaction temperature is 100-110° C., and the amount of the catalyst is 0.05-0.08% of the mass of the modified polysiloxane.

[0092] Silicone composition B1 was prepared as follows:

[0093] Get 50g hydrogen-containing polyorganosiloxan...

Embodiment 1-10

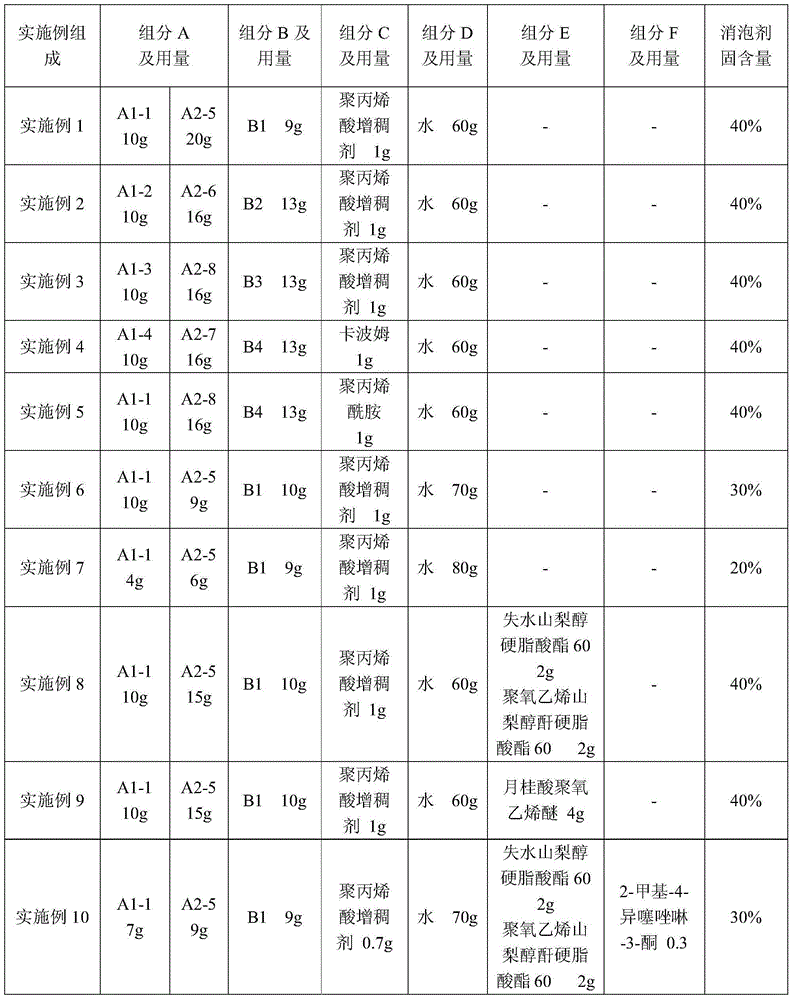

[0106] The defoamer products of Examples 1-10 were prepared respectively according to the formula in Table 2.

[0107] Table 2

[0108]

[0109] The water in the above table is deionized water.

[0110]Preparation method of Example 1-3: mix component A and component B in Table 2, heat up to 55-60°C, stir evenly; keep the temperature constant, slowly add 40-50% of the components while stirring D and 90% of component C, adjust the pH to 6.5-7. Homogenize the above emulsion, and dilute with the remaining amount of component C and component D to obtain a defoamer product with corresponding solid content.

[0111] Preparation method of Example 4-7: mix component A and component B in Table 2, heat up to 60-70°C, stir evenly; keep the temperature constant, slowly add 30-35% of the components while stirring D and 85% of component C, adjust the pH to 6.5-7. Homogenize the above emulsion, and dilute with the remaining amount of component C and component D to obtain a defoamer pro...

Embodiment 10

[0113] The preparation method of Example 10: mix component A, component B and component E in Table 2, heat up to 50-80°C, and stir evenly; keep the temperature constant, and add 30-40% of component Divide D and 85% of component C, and adjust the pH to 6.5-7. Homogenize the above emulsion, dilute with the remaining amount of component C and component D, and add component F to obtain a defoamer product with corresponding solid content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com