Paving method of seed crystals, pseudo-single crystal silicon wafer and preparation method of pseudo-single crystal silicon wafer

A laying method, quasi-single crystal technology, applied in the direction of single crystal growth, chemical instruments and methods, crystal growth, etc. Dislocation sources and other issues can be reduced to reduce the probability of dislocation, the elastic modulus is small, and the effect of reducing dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for laying a seed crystal, which is used for casting a quasi-single crystal silicon wafer, comprises the following steps:

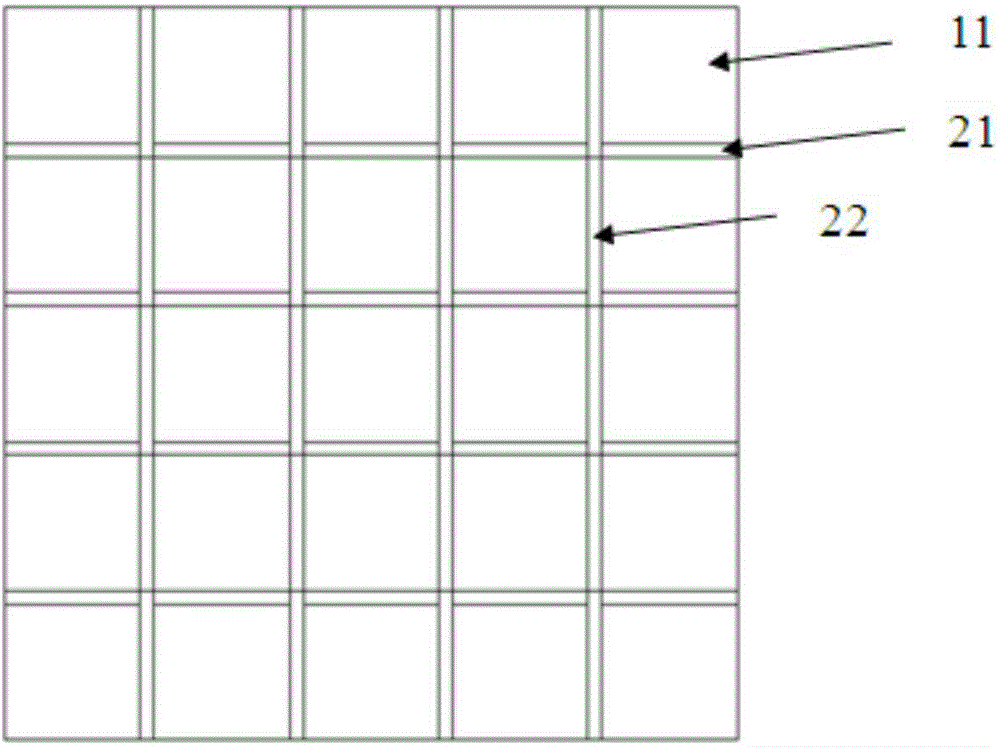

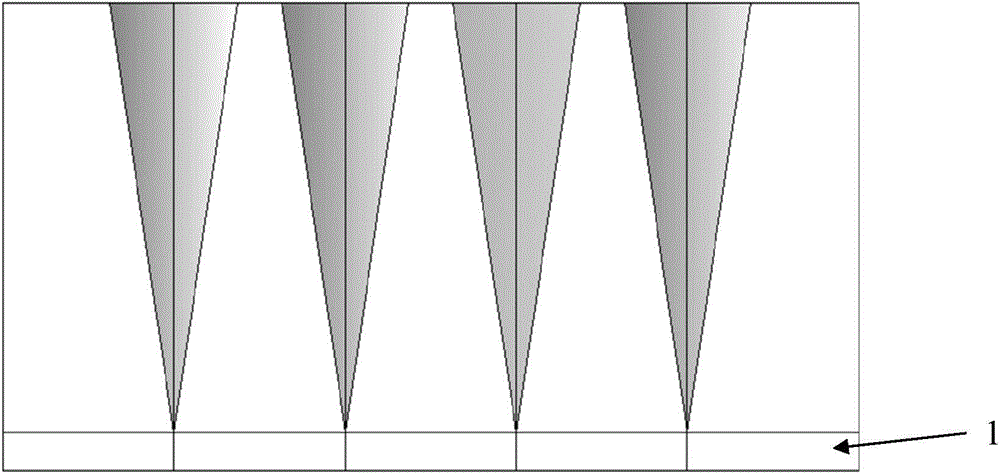

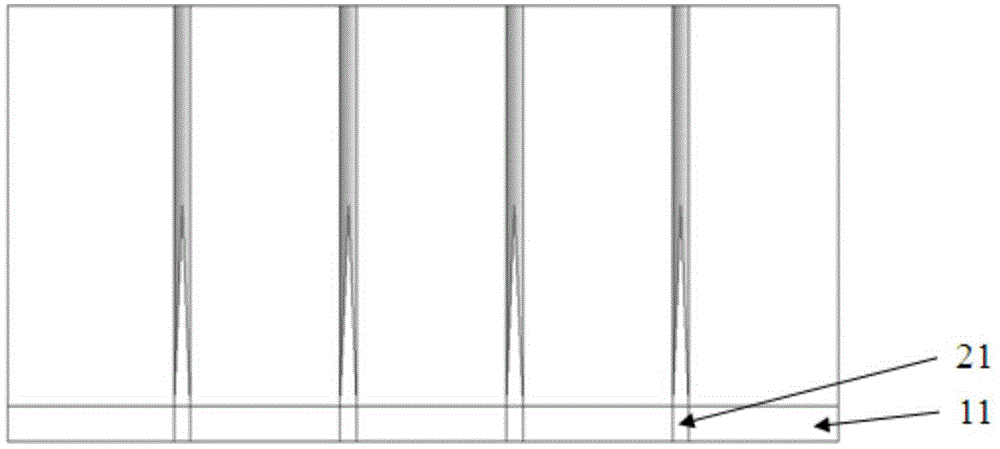

[0043] Provide a crucible, select a square seed crystal with a growth plane orientation of (100) and a side crystal orientation of (110) as the target seed crystal 11, press 5 Lay flat on the bottom of the crucible in a manner of ×5, leave a gap between adjacent target seed crystals, and fill a piece of anisotropic seed crystal 21 with a thickness of 20mm and a cross-sectional size of 156mm*10mm or a cross-sectional size of 176mm*10mm in the gap Anisotropic seed crystal 22, the crystal orientation of the growth plane of the anisotropic seed crystal is (310), and the crystal orientation of the side surface is (100). The close contact between the target seed crystal and the anisotropic seed crystal covers the bottom of the crucible to obtain a seed crystal layer. The thickness of the seed layer is 2cm;

[0044] figure 1 It is a diagram of ...

Embodiment 2

[0046] A method for preparing a quasi-single crystal silicon wafer, comprising the following steps:

[0047] (1) Provide a crucible, select a square seed crystal with a growth plane crystal orientation of (100) and a side crystal orientation of (110) as the target seed crystal, and place 25 target seed crystals with a cross-sectional size of 156mm*156mm and a thickness of 20mm 11 Lay it on the bottom of the crucible in a 5×5 pattern, leave a gap between adjacent target seed crystals, and fill the gap with an anisotropic seed crystal 21 with a thickness of 20mm and a cross-sectional size of 156mm*10mm or a cross-sectional size of 176mm *10mm anisotropic seed crystal 22, the growth surface of the anisotropic seed crystal is (310), the side crystal orientation is (100), the target seed crystal and the anisotropic seed crystal are in close contact with the bottom of the crucible, and the seed crystal is obtained layer, the thickness of the seed layer is 2cm, and the side crystal d...

Embodiment 3

[0058] A method for preparing a quasi-single crystal silicon wafer, comprising the following steps:

[0059] (1) Provide a crucible, select a square seed crystal with a growth plane crystal orientation of (100) and a side crystal orientation of (210) as the target seed crystal, and press 25 target crystal crystals with a cross-sectional size of 156mm*156mm and a thickness of 20mm Spread on the bottom of the crucible in a 5×5 manner, leaving a gap between adjacent target seed crystals, filling the gap with an anisotropic seed crystal with a thickness of 20mm and a cross-sectional size of 156mm*10mm or a cross-sectional size of 176mm*10mm The anisotropic seed crystal, the crystal orientation of the growth plane of the anisotropic seed crystal is (221), and the crystal orientation of the side surface is (110), and the close contact between the target seed crystal and the anisotropic seed crystal covers the bottom of the crucible to obtain a seed crystal layer; The thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com