High-impurity molten silicon high-pressure gas-blow separation device and method

A technology of blowing separation and impurities, which is applied in chemical instruments and methods, single crystal growth, polycrystalline material growth, etc., can solve the problems of high cost of high impurity areas, reduced yield rate, and impact on the utilization rate of silicon ingots. The effect of reducing cost and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

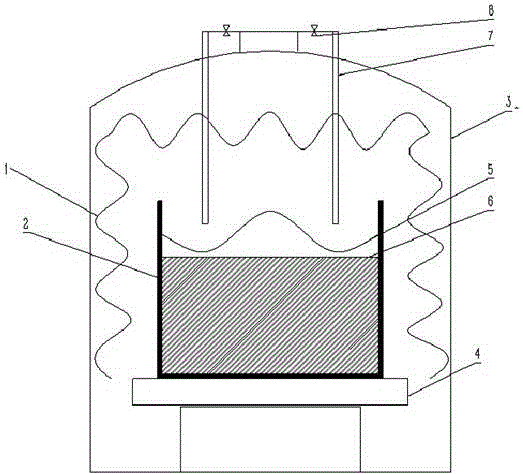

[0015] Such as figure 1 Shown: the device for separating high-impurity molten silicon by high-pressure air blowing of the present invention includes a furnace body 3, a graphite base 4 is arranged at the lower part of the furnace body 3, and a crucible 2 for loading polysilicon material is provided on the graphite base 4, In the furnace body 3, a heating body 1 connected to the system control device is arranged on the periphery of the crucible 2. Above the furnace body 3, there is a gas blowing pipe 7 with a control valve 8 connected to the gas supply device. The gas outlet of the gas blowing pipe 7 The ends face the bottom surface inside the crucible 2 and are distributed between the center of the crucible 2 and the inner surface of the crucible.

[0016] The device of the present invention that uses high-pressure gas blowing to separate high-impurity molten silicon heats and solidifies polycrystalline silicon to remove impurities, and the steps are as follows:

[0017] 1. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com