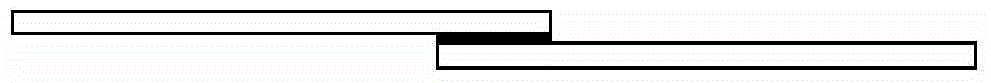

Apparatus and test method for testing structural adhesive interface bond shear strength

A technology of shear strength and interface bonding, which is applied in the direction of measuring devices, using stable shear force to test the strength of materials, and the preparation of test samples, which can solve the problems of cross specimen inclination, silicone structural adhesive shearing, etc. Problems such as poor performance and affecting the accuracy of test results, etc., to achieve the effects of avoiding torsion or eccentricity, easy to maintain stability, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Structural adhesive interface normal temperature bond shear strength test:

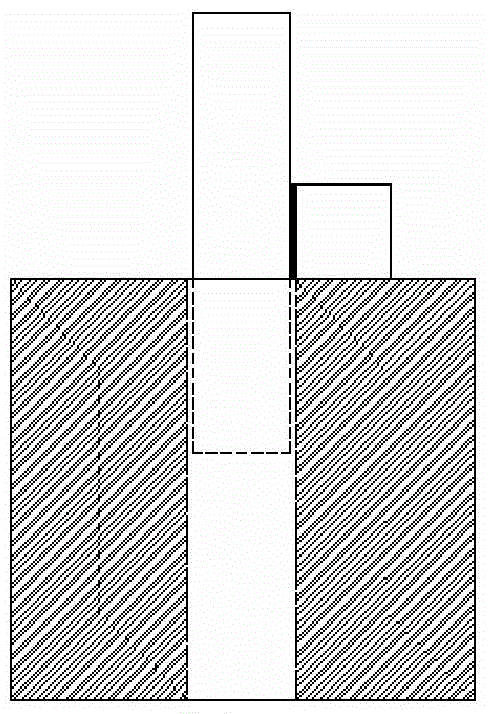

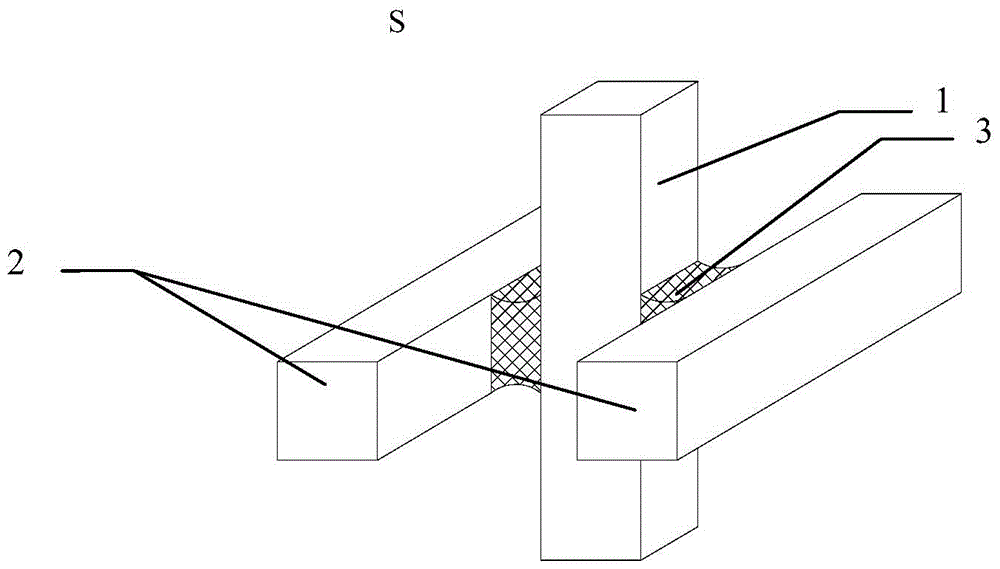

[0065] Sample: Double-sided cross-type test device S, in which,

[0066] Adhesive substrate test piece 1 is an aluminum alloy profile of 12mm×12mm×100mm,

[0067] Bonded specimen 2 is common float glass of 12mm×12mm×100mm,

[0068] The structural glue is: one-component silicone structural glue, the coating thickness is 6mm, and the coating area is 12mm×12mm.

[0069] The result of the test, the shear strength σ c =1.82MPa, the design requirement (Table 1) is not less than 1.5MPa, which meets the design requirement.

Embodiment 2

[0070] Example 2: Bond shear strength test after structural adhesive aging:

[0071] Sample: Double-sided cross-type test device S, in which,

[0072] Adhesive substrate test piece 1 is an aluminum alloy profile of 12mm×12mm×100mm,

[0073] Bonded specimen 2 is common float glass of 12mm×12mm×100mm,

[0074] The structural glue is: one-component silicone structural glue, the coating thickness is 6mm, and the coating area is 12mm×12mm.

[0075] Aging treatment of the double-sided cross-type test device S: take it out after soaking in a water bath at (45±1)°C for 21 days, and test it after placing it at room temperature for 1 day.

[0076] The result of the test, the shear strength σ c = 1.13MPa, the design requirement (Table 1) is that the shear strength after aging is not less than 1.4MPa, which does not meet the design requirement.

[0077] Comparative Test:

[0078] Specimen: single-sided cross-shaped specimen, in which,

[0079] The bonded substrate specimen is an alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com