Multiphase Effect Wastewater Advanced Treatment Reactor

A technology of advanced treatment and reactor, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of difficult discharge standards, and achieve small footprint and low cost Efficient treatment, high CODCr removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

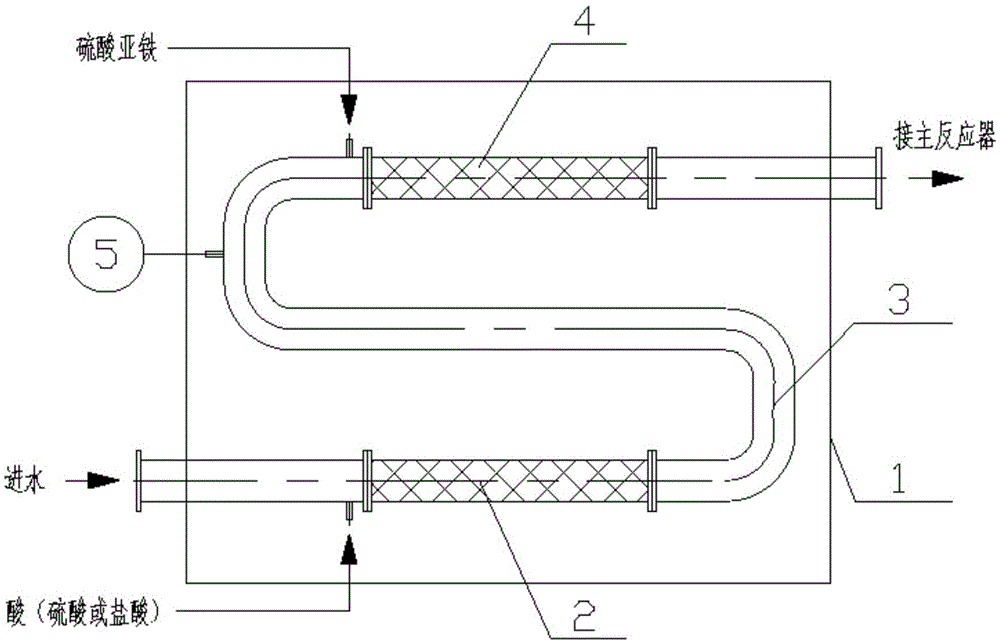

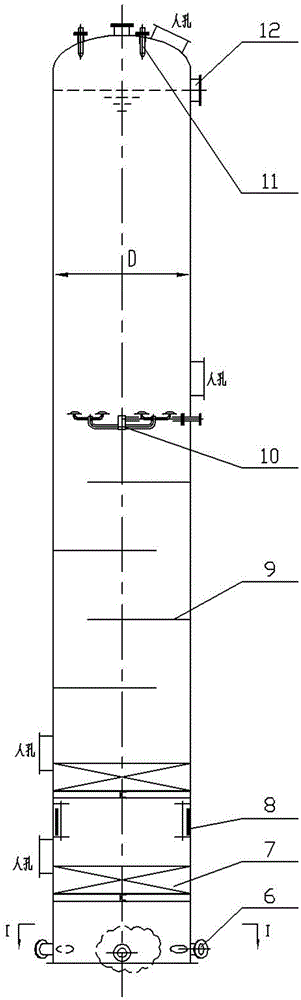

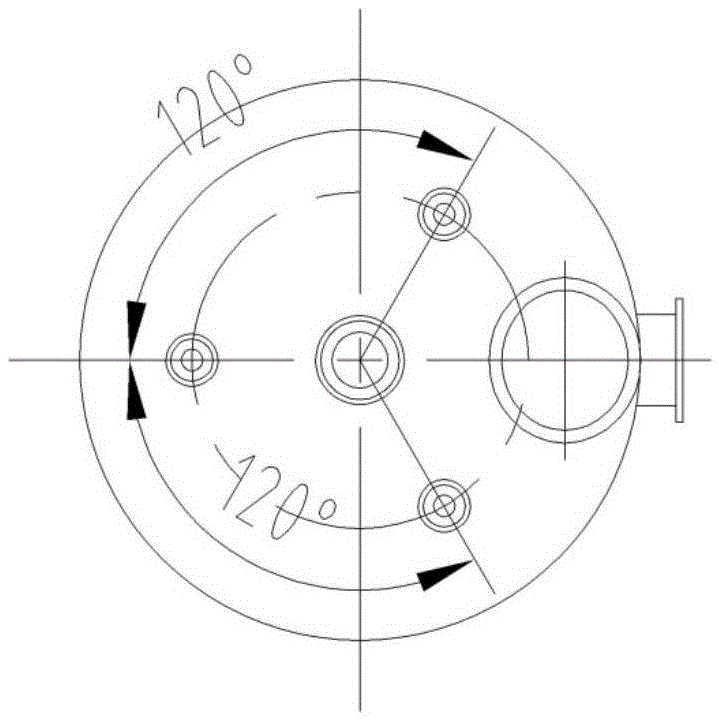

[0030] The heterogeneous effect wastewater advanced treatment reactor includes a pre-reactor 13 and a main reactor 14, the pre-reactor includes an inlet and an outlet, and two static mixers are connected between the inlet and the outlet through a connecting pipeline 3, Respectively the first static mixer 2 and the second static mixer 4, the static mixer is arranged in the steel frame 1, the pipeline between the static mixers is provided with a pH measuring device 5, the upstream of the static mixer Filling ports are provided on the pipelines; the main reactor is a hollow reaction tower, the bottom of the tower is provided with a swirl water inlet distributor 6, and the upstream of the swirl water inlet distributor is provided with a filling port. There are at least two catalyst layers 7, a group of baffles 9, an aerator 10 and a spray defoamer 11, a high-frequency catalytic system 8 is provided between the catalyst layers, and a water outlet device 12 is provided at the top of ...

Embodiment 2

[0043]The heterogeneous effect wastewater advanced treatment reactor includes a pre-reactor 13 and a main reactor 14, the pre-reactor includes an inlet and an outlet, and two static mixers are connected between the inlet and the outlet through a connecting pipeline 3, Respectively the first static mixer 2 and the second static mixer 4, the static mixer is arranged in the steel frame 1, the pipeline between the static mixers is provided with a pH measuring device 5, the upstream of the static mixer Filling ports are provided on the pipelines; the main reactor is a hollow reaction tower, the bottom of the tower is provided with a swirl water inlet distributor 6, and the upstream of the swirl water inlet distributor is provided with a filling port. There are two catalyst layers 7, a group of baffles 9, an aerator 10 and a spray defoamer 11, a high-frequency catalytic system 8 is arranged between the catalyst layers, and a water outlet device 12 is arranged at the top of the tower;...

Embodiment 3

[0045] The heterogeneous effect wastewater advanced treatment reactor includes a pre-reactor 13 and a main reactor 14, the pre-reactor includes an inlet and an outlet, and two static mixers are connected between the inlet and the outlet through a connecting pipeline 3, Respectively the first static mixer 2 and the second static mixer 4, the static mixer is arranged in the steel frame 1, the pipeline between the static mixers is provided with a pH measuring device 5, the upstream of the static mixer Filling ports are provided on the pipelines; the main reactor is a hollow reaction tower, the bottom of the tower is provided with a swirl water inlet distributor 6, and the upstream of the swirl water inlet distributor is provided with a filling port. There are two catalyst layers 7, a group of baffles 9, an aerator 10 and a spray defoamer 11, a high-frequency catalytic system 8 is arranged between the catalyst layers, and a water outlet device 12 is arranged at the top of the tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com