High-hardness impact-resistant heat-insulation foamed plastic

A foamed plastic and impact-resistant technology, applied in the field of foamed plastics, can solve the problems of unsatisfactory effect, difficult to achieve uniform impact resistance and hardness of foamed plastics, achieve uniform bubbles, no shrinkage and warping, and improve oxidation resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

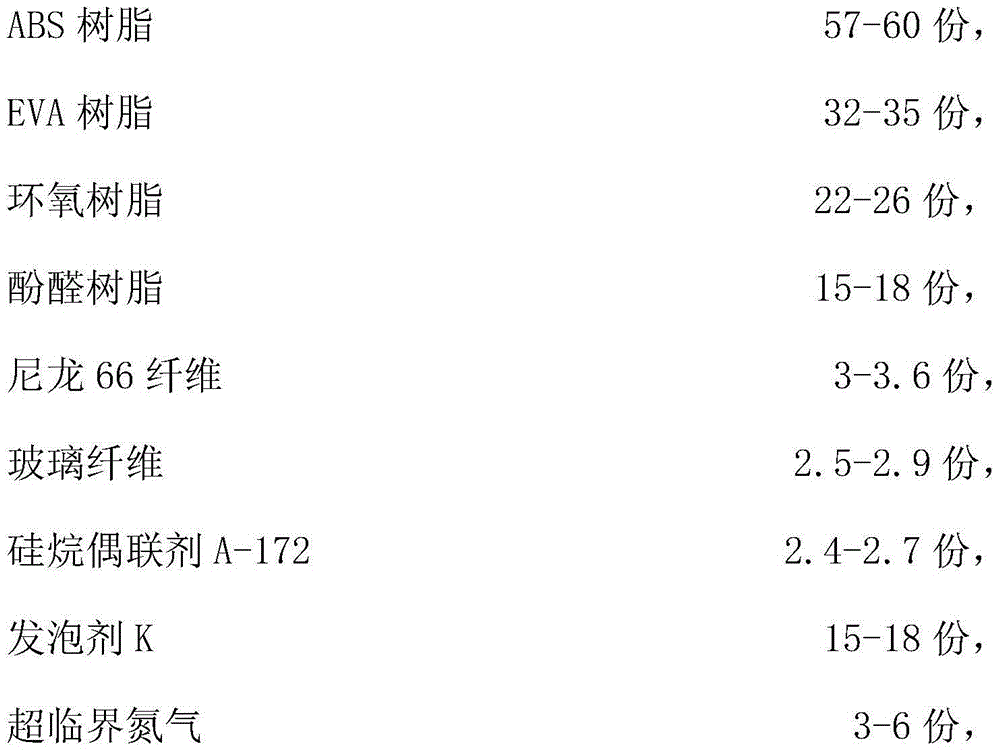

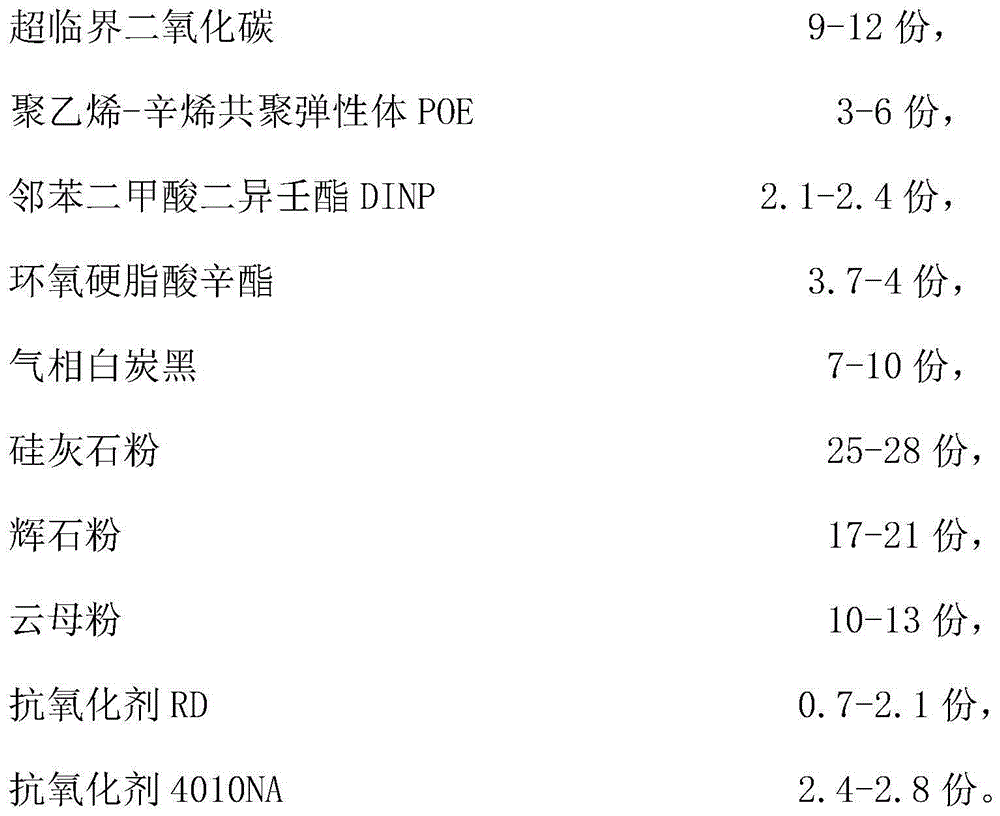

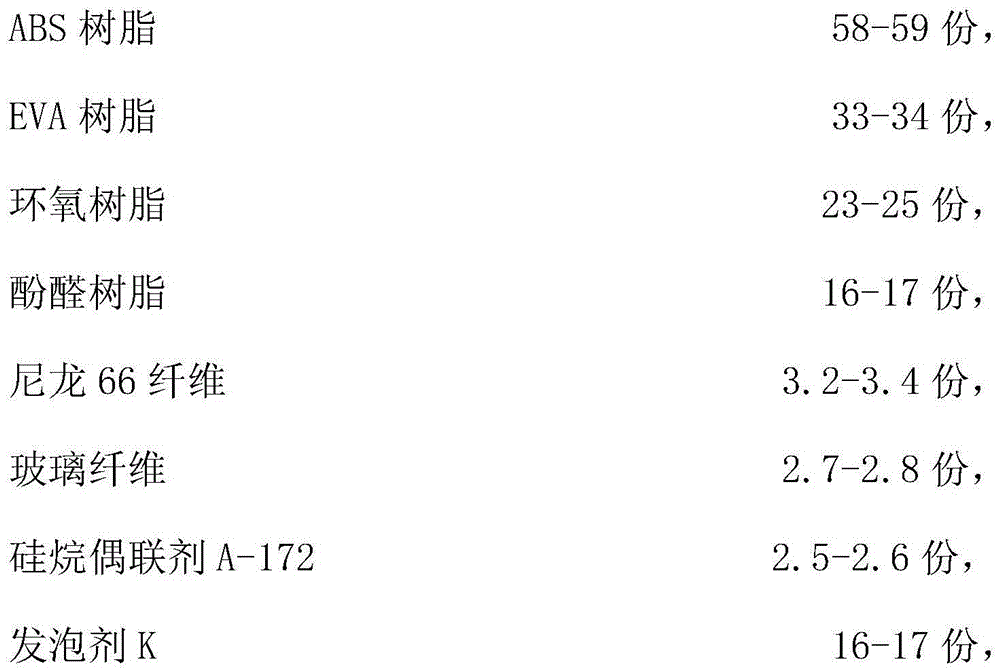

[0014] Next, the technical solution of the present invention will be described in detail through specific examples. In Examples 1-4, the raw materials of a high-hardness, impact-resistant and heat-insulating foamed plastic proposed by the present invention are composed as shown in the following table in parts by weight.

[0015]

[0016]

[0017] Wherein, the weight ratio of acrylonitrile, butadiene and styrene of the ABS resin in Example 1 is 29:28:47, and the Shore hardness of the polyethylene-octene copolymerized elastomer POE is 72HA; Acrylonitrile, butadiene and styrene weight ratio are 32:27:49, and the vinyl acetate content of EVA resin is 12wt%; The vinyl acetate content of EVA resin is 16wt% among the embodiment 3, polyethylene-octene copolymerization elastomer The shore hardness of POE is 80HA; the weight ratio of acrylonitrile, butadiene and styrene of ABS resin in embodiment 4 is 30:27.5:48, the vinyl acetate content of EVA resin is 14wt%, polyethylene-octene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com