Device and method for controlling fine particle emission in wet flue gas desulfurization

A technology for wet flue gas desulfurization and fine particles, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of difficulty in adding seed particles, reduce the energy consumption of sonic agglomeration, and low efficiency of sonic agglomeration, and achieve improved Agglomeration growth efficiency, simplification of operating process and operating costs, and the effect of reducing sound pressure level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

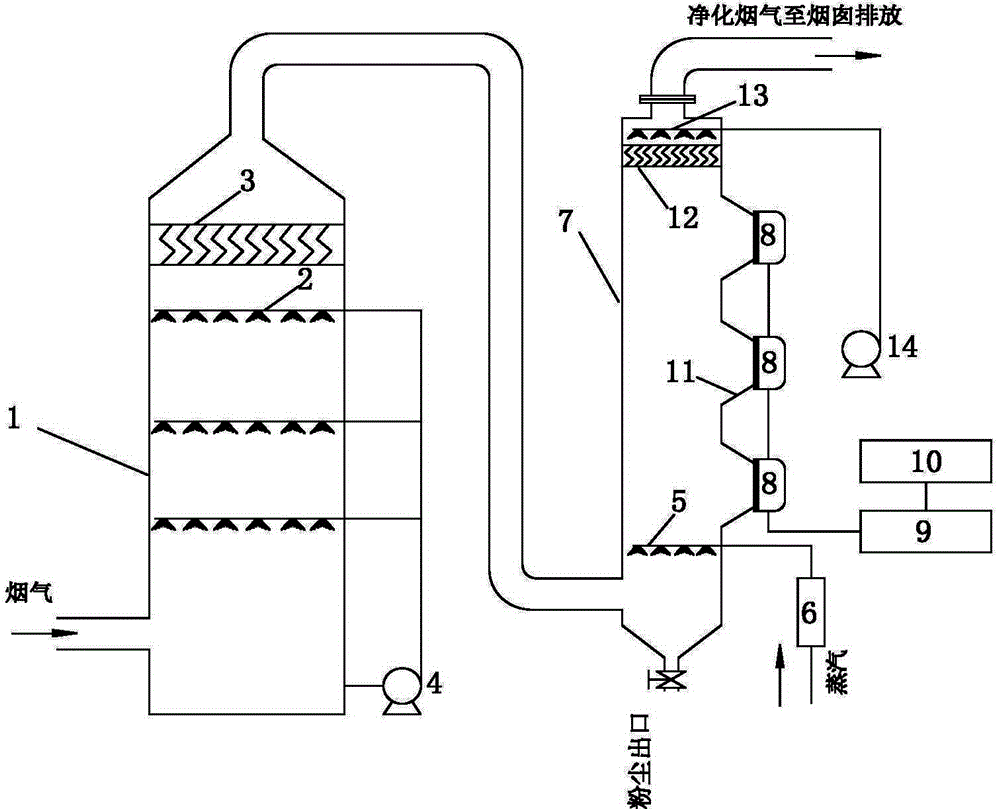

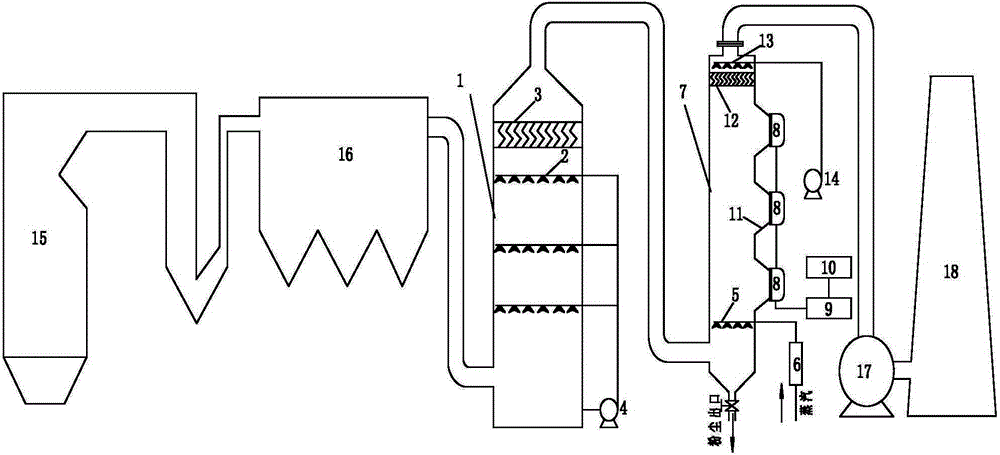

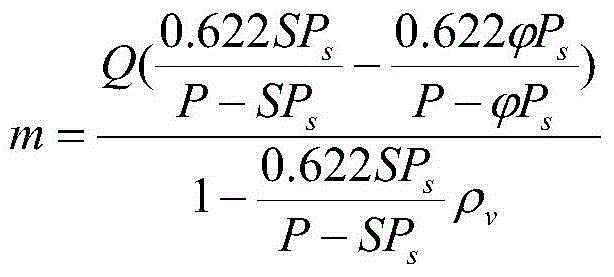

[0025] A device for controlling the emission of fine particles from wet flue gas desulfurization, such as figure 1As shown, it includes a wet flue gas desulfurization tower 1 and an acoustic agglomeration chamber 7. The wet flue gas desulfurization tower 1 is equipped with three sets of parallel desulfurization liquid nozzles 2 and a desulfurization demister 3. The desulfurization demister 3 is set in the desulfurization above the liquid nozzle 2. The top outlet of the wet flue gas desulfurization tower 1 communicates with the lower entrance of the acoustic agglomeration chamber 7, wherein the acoustic agglomeration chamber 7 includes a diffused steam nozzle 5, a steam mass flow controller 6, an acoustic wave generating unit, a demister 12 and a flushing Nozzle 13. The sound wave generating unit includes up to three sound sources 8, a power amplifier 9, a signal generator 10 and a retractable telescopic diffuser tube 11. The sound source 8 is connected to the power amplifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com