Automatic tin soldering device of transformer

An automatic welding and transformer technology, applied in the direction of tin feeding device, auxiliary device, welding equipment, etc., can solve the problems of high work intensity and low efficiency, and achieve the effects of reducing labor costs, reasonable overall layout, and accelerating welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

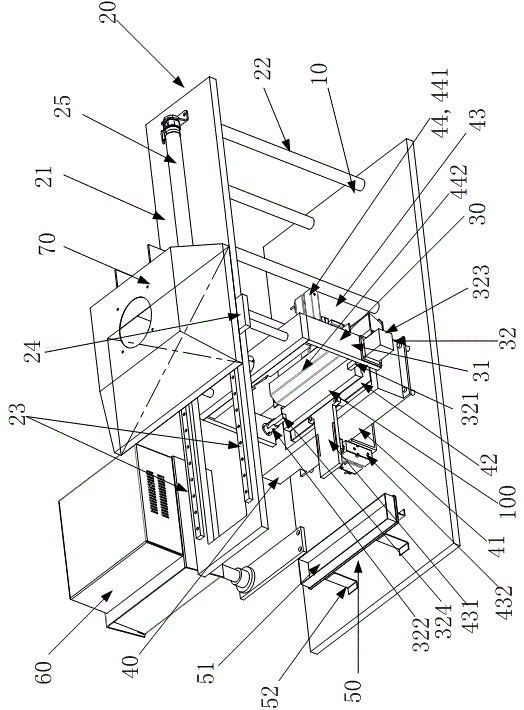

[0010] Specific embodiments of the present invention are described with reference to the above drawings.

[0011] Depend on figure 1 It can be seen from the figure that this transformer automatic soldering device includes a frame 10, a horizontal feeding mechanism 20 fixed on the frame 10, a work material holder that is suspended on the horizontal feeding mechanism 20 and can move horizontally on the horizontal feeding mechanism. Mechanism 30, solder tank 40 and auxiliary solder tank 50 located on the frame 10 and below the material clamping mechanism 30, the automatic soldering device also includes controls for controlling the work of the above-mentioned mechanisms and tanks system60. This automatic soldering machine adopts the method of manually clamping the material rack on the material clamping mechanism, or further configures the automatic feeding mechanism, etc. The soldering process completely uses the control system to complete the welding process and related cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com