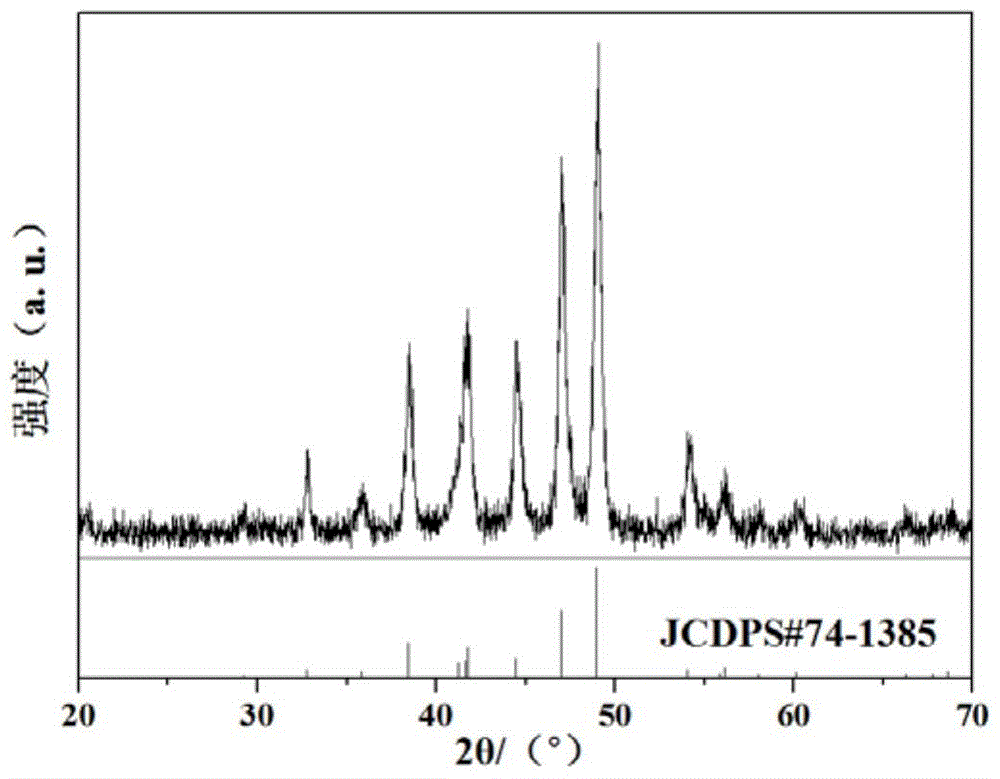

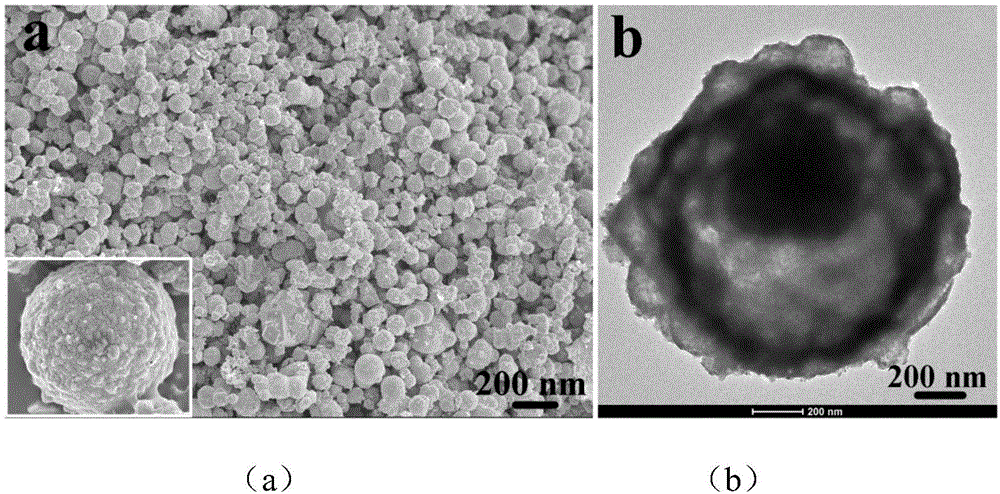

Preparation method for nickel phosphide with hollow core-shell structure

A core-shell structure, nickel phosphide technology, applied in the direction of phosphide, etc., to achieve the effect of easy control of reaction conditions, high repeatability, and high photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing nickel phosphide with a hollow core-shell structure, comprising the following steps:

[0037] 1) Add 8-22 mL of deionized water to the polytetrafluoroethylene lining of the reaction kettle, weigh 0.1-2 g of soluble nickel salt into the deionized water, and stir on a magnetic stirrer until dissolved;

[0038] 2) Add 0.01-0.5g of anionic surfactant and 0.01-0.5g of cationic surfactant, stir until completely dissolved;

[0039] 3) Add 0.1-2g of elemental phosphorus to the solution, then seal the polytetrafluoroethylene lining into a stainless steel mold, and heat it from room temperature to 100-200°C under airtight conditions for 0.1-24h;

[0040] 4) After the reaction is completed, the resulting black precipitate is transferred to a centrifuge tube, washed several times with benzene, water, and absolute ethanol and centrifuged;

[0041] 5) Put the washed product into a vacuum drying oven at 50-60°C for 4-8 hours to obtain nickel phosphide Ni with a...

Embodiment 2

[0048] In embodiment 1 step 2) the quality of anionic surfactant and cationic surfactant becomes 0.01~0.3g and 0.03~0.4 respectively, other conditions are constant, product is compared with embodiment 1, to Congo red and saffron T The degradation rates of organic dyes were 78% and 56%, respectively.

Embodiment 3

[0050] In embodiment 1 step 2) the quality of anionic surfactant and cationic surfactant becomes 0.03~0.4 and 0.01~0.3g respectively, other conditions are constant, product is compared with embodiment 1, to Congo red and saffron T The degradation rates of organic dyes were 89% and 63%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com