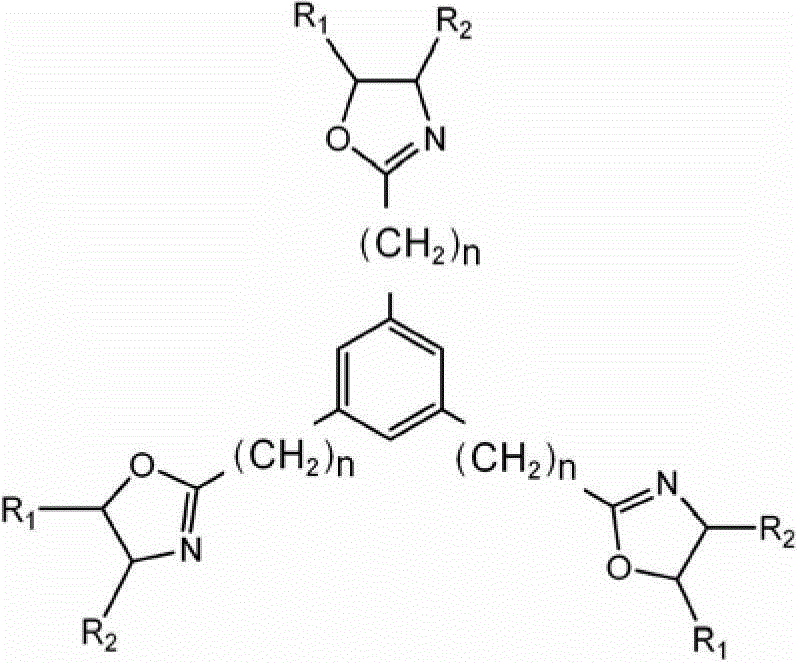

1,3,5-benzenetricarboxylic acid derivative and making method thereof

A technology of trimenetricarboxylic acid and trimenetricarboxylate, applied in coatings, organic chemistry, powder coatings, etc., can solve problems such as inability to completely replace TGIC, inferiority, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

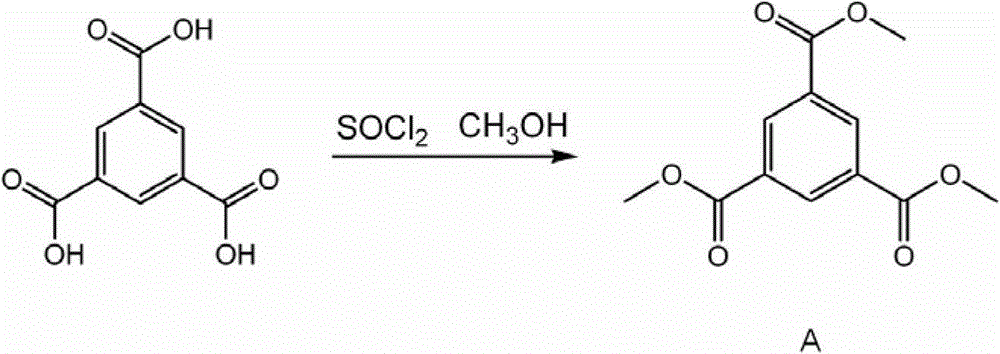

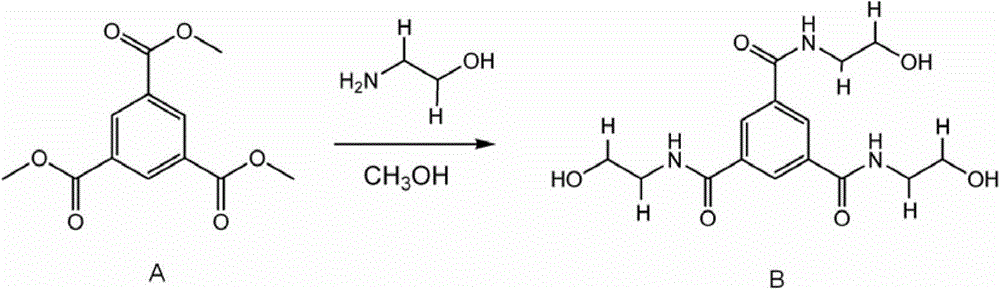

[0017] A preferred embodiment of the present invention is to first prepare trimethylenetricarboxylate (trimethyl1,3,5-benzenetricarboxylate), and then use trimellitic acid methyl ester to manufacture 1,3,5-tri(2-oxazoline base) ) Benzene (1,3,5-tris(2-oxazolidinyl-2-y1)benzene, hereinafter referred to as TOX-1). The detailed implementation steps and reaction formula are as follows:

[0018] Preparation of trimethyl trimesate

[0019] Take a four-neck bottle, install a mechanical stirrer, a condenser tube and a thermometer, weigh trimesic acid (1.0 equiv), add solvent methanol (7.0 equiv), and heat up to 35-40°C. Add thionyl chloride (3.4 equiv) slowly, control the temperature to 40°C, and stir for 3 hours. Sampling is detected, and the reaction is completed if the content of the starting material is less than 1%. Then the temperature was lowered to 20°C, and a white solid was obtained by suction filtration. Wash the white solid with solvent methanol, and dry it to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com