A kind of preparation method of porous metal treatment liquid and composite material

A porous metal and treatment liquid technology, applied in the field of preparation of porous metal treatment liquid and composite materials, can solve the problems of difficult to reach the ideal level, unfavorable processing, limited bonding strength, etc., to improve the bonding force and processing process Environmental protection and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] According to an embodiment of the present invention, a method for preparing a composite material may include the following steps:

[0039] 1) Provide porous metal substrates formed by powder metallurgy sintering method, which can be but not limited to aluminum alloy 7075, aluminum alloy 6262, aluminum alloy 6063, aluminum alloy 6061, aluminum alloy 2024, aluminum alloy 2017, aluminum alloy 2011, aluminum alloy One of 5086, aluminum alloy 5052, and aluminum alloy 5083.

[0040] 2) Carry out chemical degreasing treatment on the metal substrate with degreasing agent to remove the oil stain on the metal surface; the chemical degreasing temperature is 55-85°C, and the degreasing time depends on the specific degreasing effect.

[0041] 3) Putting the porous metal substrate with micron-scale pores after surface activation treatment into the metal treatment solution for surface modification treatment. Preferred processing parameters: a) temperature: 50-80; b) time: 7-25min.

...

Embodiment 1

[0044] 1. Preparation of porous metal treatment liquid:

[0045] In 1000 parts of water, add the raw material with following weight ratio:

[0046] 1) 65 parts of inorganic alkaline agent

[0047] Wherein: potassium hydroxide 65 parts;

[0048] 2) 120 parts of organic alkaline agent

[0049] Among them: 60 parts of ammonia water, 60 parts of ethylenediamine.

[0050] 2. A preparation method of porous metal composite material, specifically comprising the following steps:

[0051] 1) Provide a shaped porous metal substrate. The porous metal substrate is a shaped metal substrate prepared by powder metallurgy, which can be aluminum alloy 7075, aluminum alloy 6262, aluminum alloy 6063, aluminum alloy One of alloy 6061, aluminum alloy 2024, aluminum alloy 2017, aluminum alloy 2011, aluminum alloy 5086, aluminum alloy 5052, aluminum alloy 5083 and other models.

[0052] 2) Carry out chemical degreasing treatment on the metal substrate with a degreasing agent sold on the market t...

Embodiment 2

[0058] 1. Preparation of porous metal treatment liquid:

[0059] In 1000 parts of water, add the raw material with following weight ratio:

[0060] 1) 128 parts of inorganic alkaline agent

[0061] Wherein: potassium hydroxide 95 parts, sodium bicarbonate 33 parts;

[0062] 2) 135 parts of organic alkaline agent

[0063] Among them: 45 parts of ammonia water, 90 parts of p-phenylenediamine.

[0064] 2. A preparation method of porous metal composite material, specifically comprising the following steps:

[0065] 1) Provide a shaped porous metal substrate. The porous metal substrate is a shaped metal substrate prepared by powder metallurgy, which can be aluminum alloy 7075, aluminum alloy 6262, aluminum alloy 6063, aluminum alloy One of alloy 6061, aluminum alloy 2024, aluminum alloy 2017, aluminum alloy 2011, aluminum alloy 5086, aluminum alloy 5052, aluminum alloy 5083 and other models.

[0066] 2) Carry out chemical degreasing treatment on the metal substrate with a degr...

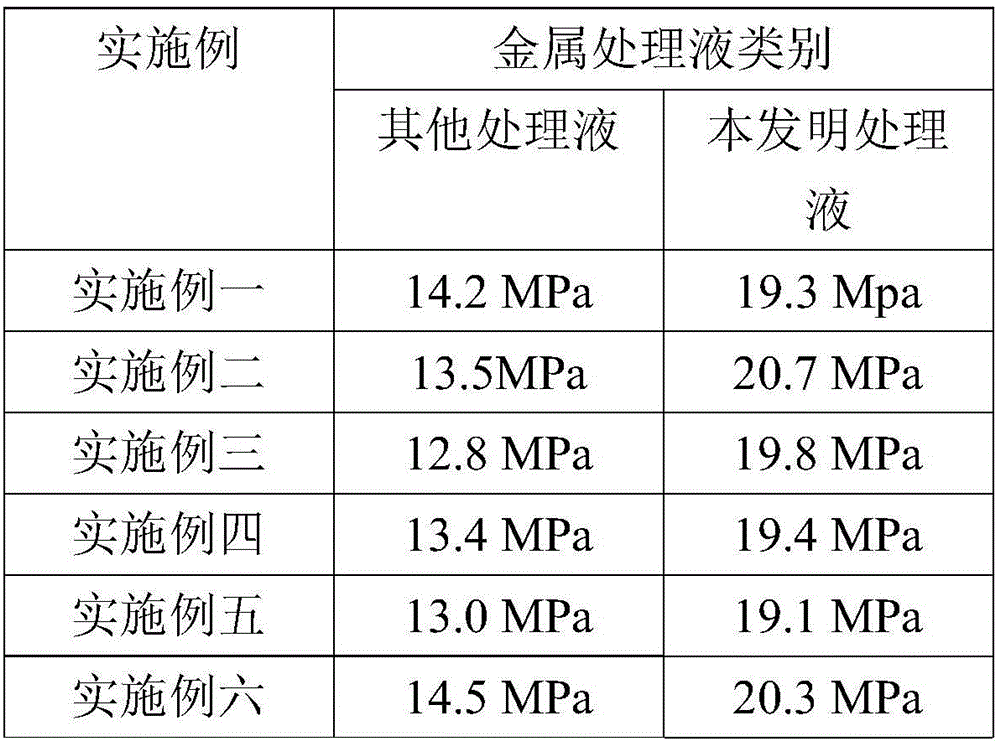

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com