Insulation fireproof building profile and manufacturing methods thereof

A technology for fire-proof buildings and manufacturing methods, which is applied in the directions of heat preservation, fire prevention, building components, etc., can solve the problems of flammability of external wall heat preservation materials, and lack of heat preservation and sound insulation of indoor gypsum decorative materials, so as to suppress large-scale occurrence, enhance heat preservation and The effect of sound insulation formation and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 A thermal insulation and fireproof building profile

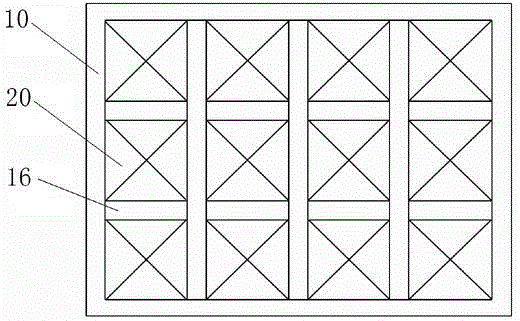

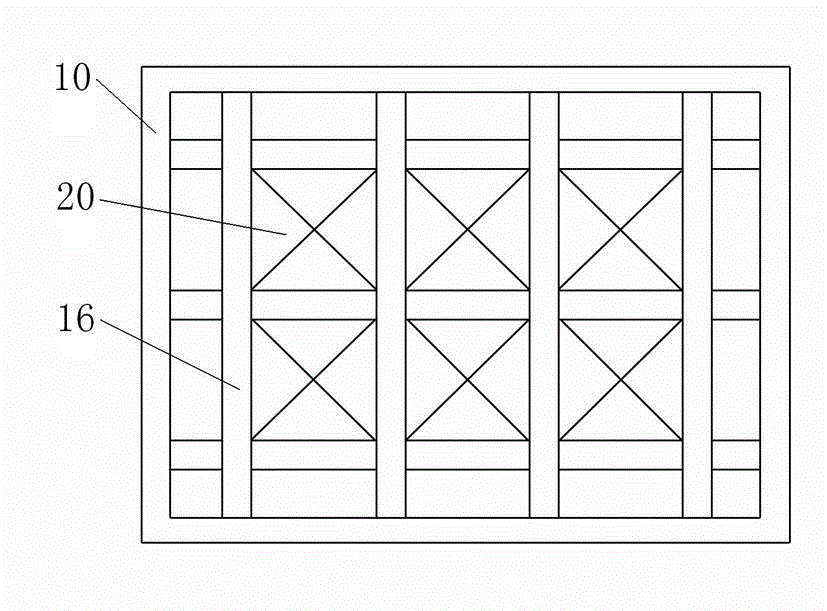

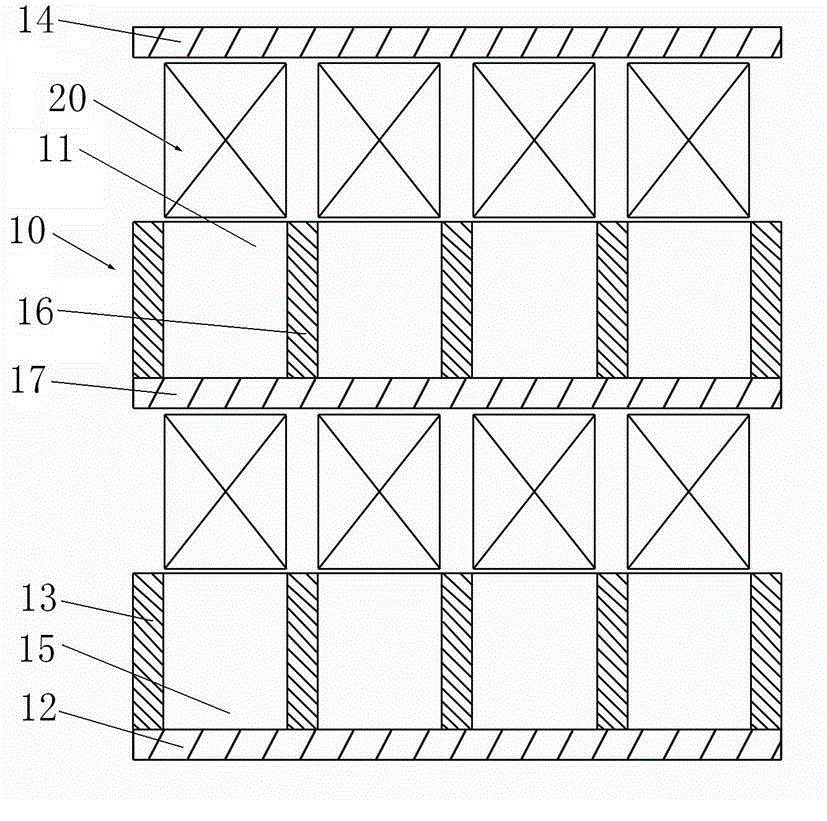

[0034] Such as Figure 1-3 As shown, the thermal insulation and fireproof building profile in this embodiment includes a square profile body 10 built with gypsum, brick material or cement material and an air storage bag 20 filled with carbon dioxide gas exceeding the normal atmospheric pressure. The carbon dioxide gas has Flame retardant and excellent thermal insulation performance, the profile body 10 is provided with a plurality of unit cavities 11 , and the air storage bag 20 is provided with multiple units, which are respectively arranged in each unit cavity 11 . The air storage bag 20 can be made of plastic or rubber material; the unit cavity 11 is square or circular. Preferably, the profile body 10 is mainly composed of a sealing layer 12, a side wall 13 and a cover plate 14, the side wall 13 is arranged on the periphery of the sealing layer 12 and connected with the periphery of the cover plate 14, ...

Embodiment 2

[0038] Example 2 A method of manufacturing thermal insulation and fireproof building profiles

[0039] The method for manufacturing thermal insulation and fireproof building profiles in this embodiment mainly includes the following steps: S1) Making gypsum boards with multiple unit cavities: making the bottom cavity 15 with multiple unit cavities 11 by mold forming The structure, specifically, lay multi-layer fiber fabrics in the forming mold first, then pour the pre-modulated gypsum slurry into the forming mold, and then make the bottom cavity 15 after the gypsum is solidified and formed;

[0040]S2) Combination: place a carbon dioxide gas storage bag 20 in the unit cavity of the cured gypsum board in step S1 to obtain a semi-finished gypsum board filled with a carbon dioxide gas storage bag, and wrap the semi-finished gypsum board with one or more layers of fiber cloth and cover the air storage bag 20, then put it into the combination mold and pour the pre-prepared gypsum sl...

Embodiment 3

[0043] Example 3 Another manufacturing method of thermal insulation and fireproof building profiles

[0044] Such as Figure 4 As shown, the manufacturing method of thermal insulation and fireproof building profiles in this embodiment mainly includes the following steps: a) Making a brick body 30 with a unit cavity: Extruding the raw materials through extrusion equipment in the molding method of making hollow bricks in the prior art Press into a hollow brick adobe containing a square or circular unit cavity 11, the unit cavity 11 runs through both sides of the hollow brick adobe, then cut the hollow adobe horizontally into a plurality of unit hollow adobes, and burn the unit hollow adobes through a sintering process into a brick body 30 with a unit cavity 11, and the thickness of the brick body 30 is not more than 10 cm; b) making the connecting plate 31: extruding the raw material into a solid brick adobe by the method of making a solid brick in the prior art, and then pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com