Structure of coaxial pulse tube refrigerator for cooling high-temperature superconductivity filter and manufacturing method thereof

A pulse tube refrigerator and high-temperature superconducting technology, which is applied in the direction of refrigerators, waveguide devices, refrigeration and liquefaction, etc., can solve the problems of reliability and working life affecting working performance, and the influence of high-temperature superconducting filter working output signals, etc. , to achieve the effect of compact structure, high reliability, and reduced cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

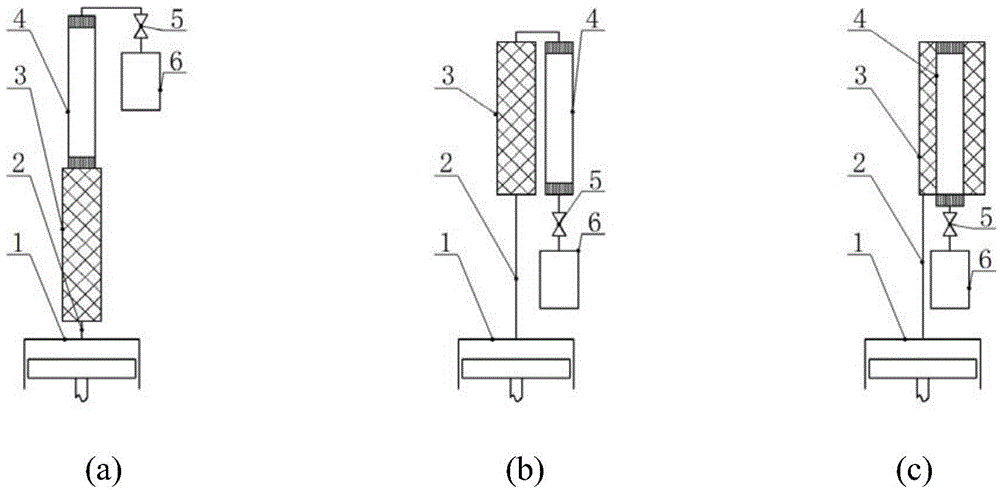

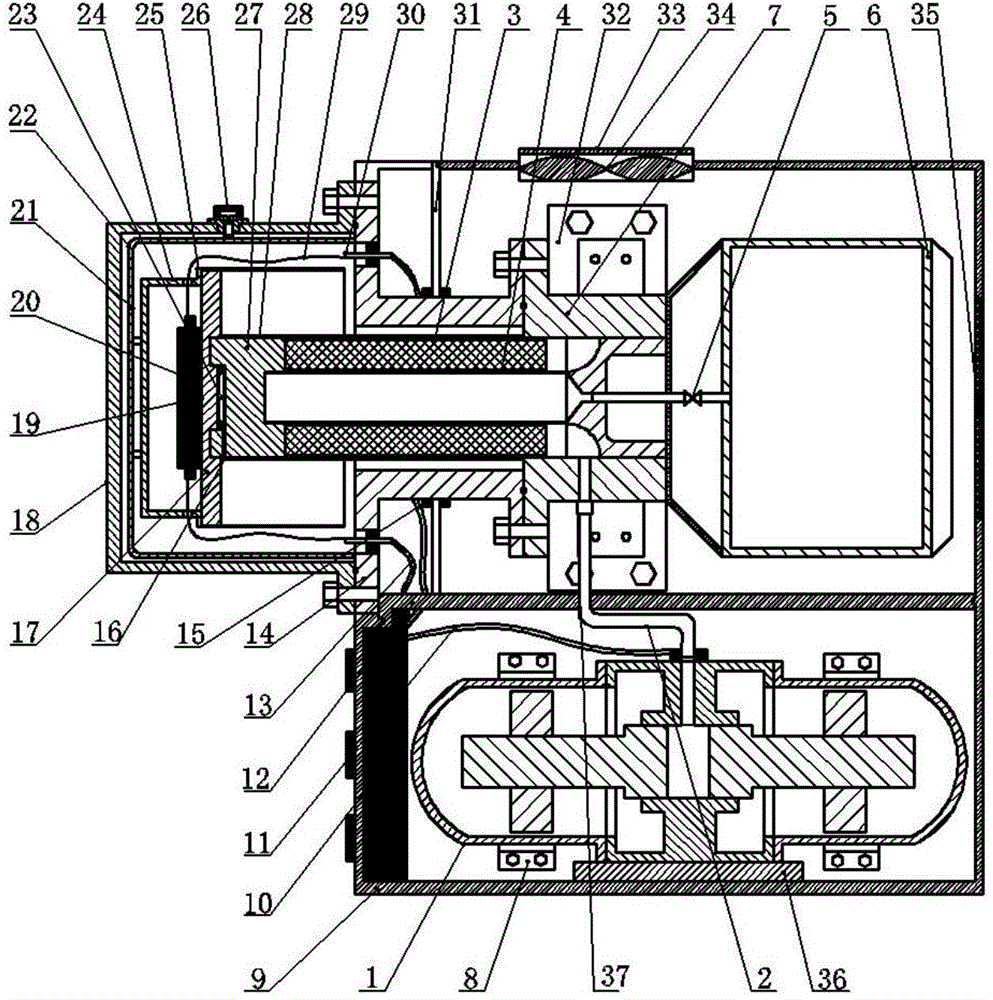

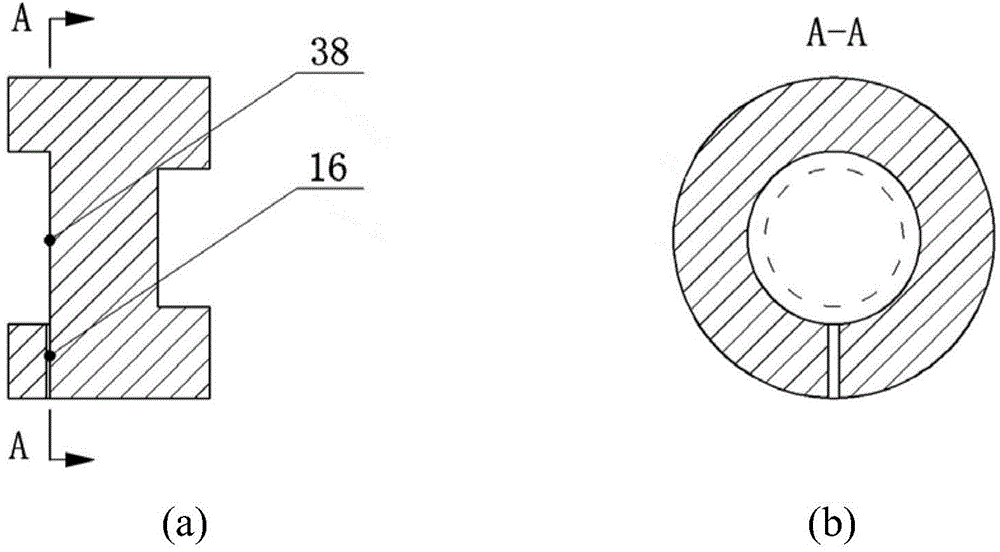

[0036] Such as figure 2 As shown, the coaxial pulse tube refrigerator is composed of structural components such as compressor 1, connecting pipe 2, regenerator 3, pulse tube 4, phase modulation mechanism 5, gas storage 6, hot end heat exchanger 7, cold head 27, etc. The pulse tube 4 is concentrically inserted into the regenerator 3, and the compressor 1 is connected to the hot-end heat exchanger 7 of the coaxial pulse tube refrigerator through the connecting pipe 2; Pulse tube 4 , hot end heat exchanger 7 , phase adjustment mechanism 5 and gas storage 6 reciprocate inside, and through the phase adjustment of phase adjustment mechanism 5 and gas storage 6 , cooling capacity is generated at cold head 27 . Cold head 27 structure such as image 3 As shown, there is a central hole 38 on its left side, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com