Preparation method of micro-expansive graphite anode material

A technology of graphite material and graphite negative electrode, which is applied in the field of preparation of micro-expanded graphite material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

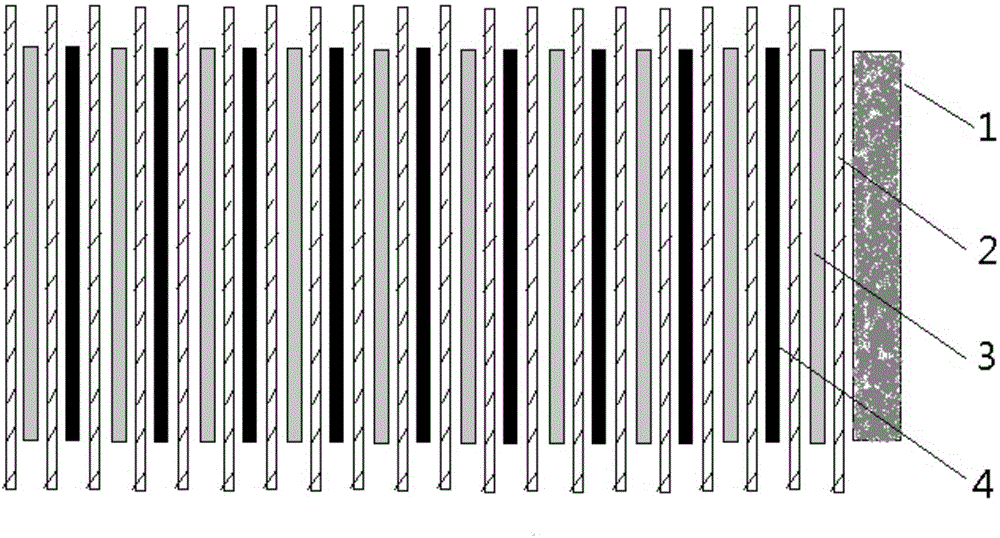

[0027] According to the micro-expanded graphite negative electrode material provided by the technical solution of the first aspect of the present invention, or the preparation method provided by the technical solution of the second aspect of the present invention, or the application provided by the technical solution of the third aspect of the present invention:

[0028] 1) In some embodiments, during the oxidation intercalation, the reaction system is also stirred.

[0029] 2) In some embodiments, after the solid is washed until the pH of the filtrate is 6-7, the solid is washed with absolute ethanol and then dried.

[0030] 3) In some embodiments, the mass ratio of the battery-grade graphite powder material to the oxidizing agent and the intercalation agent is 1:0.2-0.6:2-5.

[0031] 4) In some embodiments, the drying is vacuum drying at a temperature of 60-70° C.; the vacuum drying time is 6-12 hours.

[0032] 5) In some embodiments, the puffing temperature is 400-650° C.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com