Coal gasification pressurized molten carbonate fuel cell hybrid power system with CO2 recycling function

A molten carbonate and fuel cell technology, applied in molten electrolyte fuel cells, fuel cells, circuits, etc., to achieve improved efficiency, high energy conversion efficiency, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

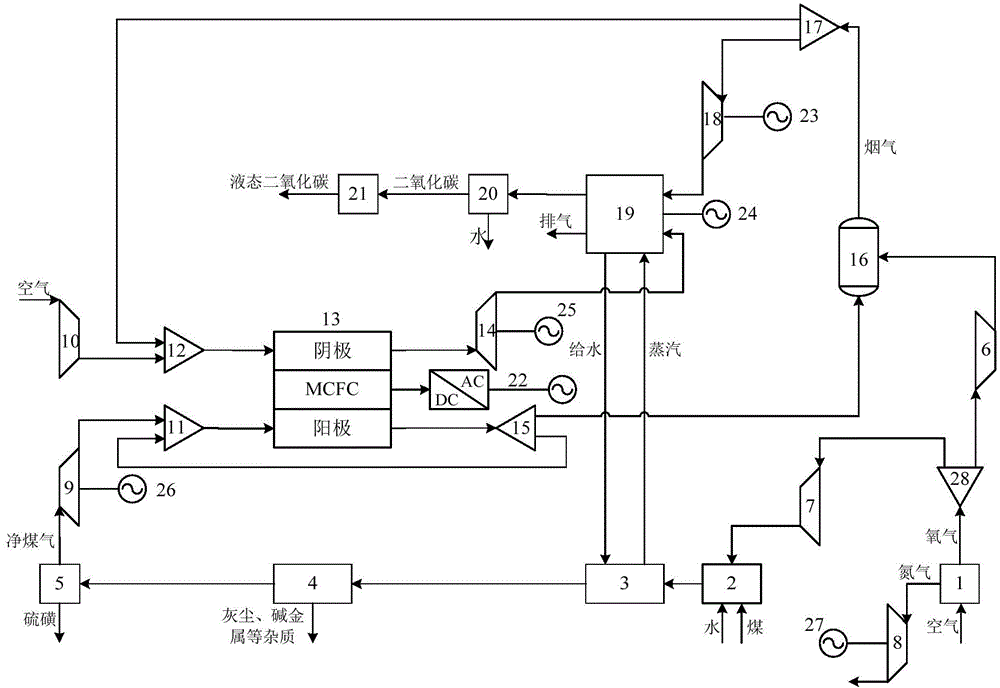

[0021] The invention provides a CO recovery 2 The coal gasification pressurized molten carbonate fuel cell composite power system, the present invention will be further described below through the description of the drawings and specific embodiments.

[0022] Process flow of the present invention such as figure 1 As shown: the oxygen separated by the cryogenic air separation unit 1 is divided into two paths through the third separator 28, one path is compressed by the second oxygen compressor 6 and enters the afterburner 16 to participate in pure oxygen combustion, and the other path passes through the first After being compressed by the oxygen compressor 7, it enters the gasifier 2 for coal gasification reaction with coal and water, and the synthesized crude gas passes through the gas cooler 3, the dust removal unit 4, and the acid gas removal unit 5 in turn to generate clean gas, which passes through the gas After the expander 9 expands and works and drives the fourth gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com