Copolymer for lithography and method for manufacturing same, resist composition, and method for manufacturing substrate

一种共聚物、基团的技术,应用在半导体/固态器件制造、用于光机械设备的光敏材料、光学等方向,能够解决抗蚀剂组合物灵敏度不充分、配制抗蚀剂组合物困难、增加制造工序数等问题,达到灵敏度良好、溶解性良好、高灵敏度的效果

Active Publication Date: 2014-11-19

MITSUBISHI CHEM CORP

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] If the composition of the monomer units in the copolymer is different, the solubility in the solvent is likely to be uneven. When preparing a resist composition, it takes a long time to dissolve it in the solvent, or it needs to be increased due to the generation of insoluble components. The number of manufacturing steps, etc., brings difficulties to the preparation of resist compositions

In addition, the sensitivity of the obtained resist composition tends to become insufficient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

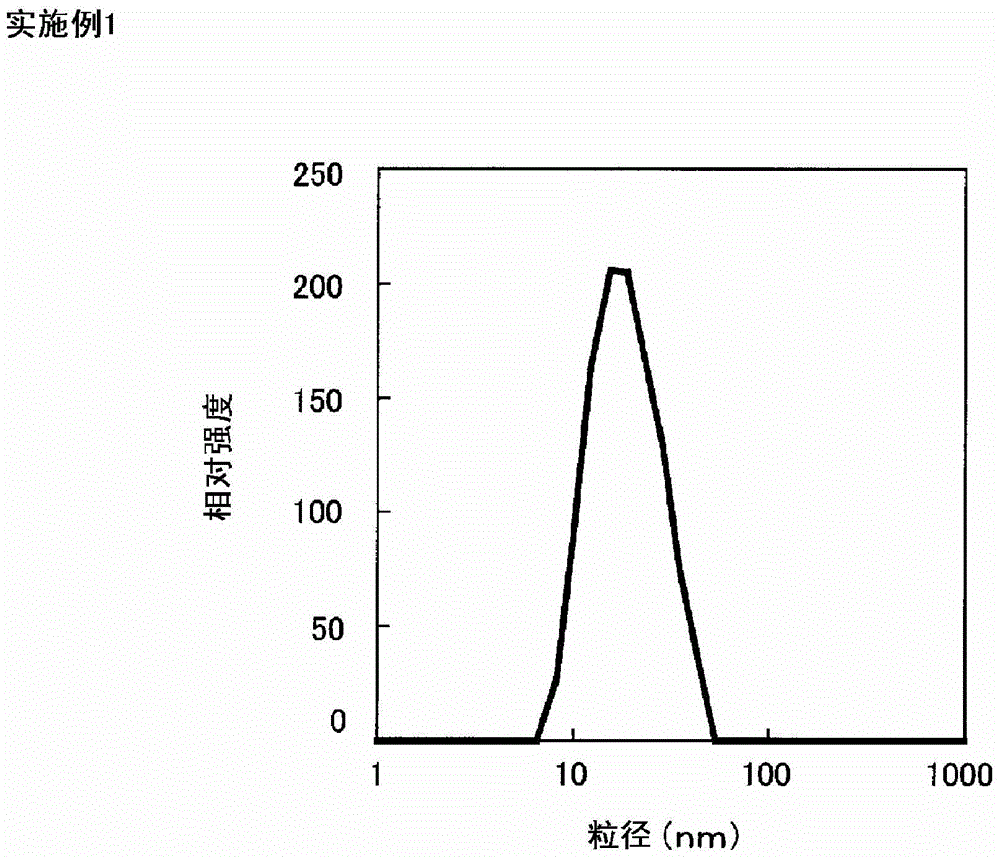

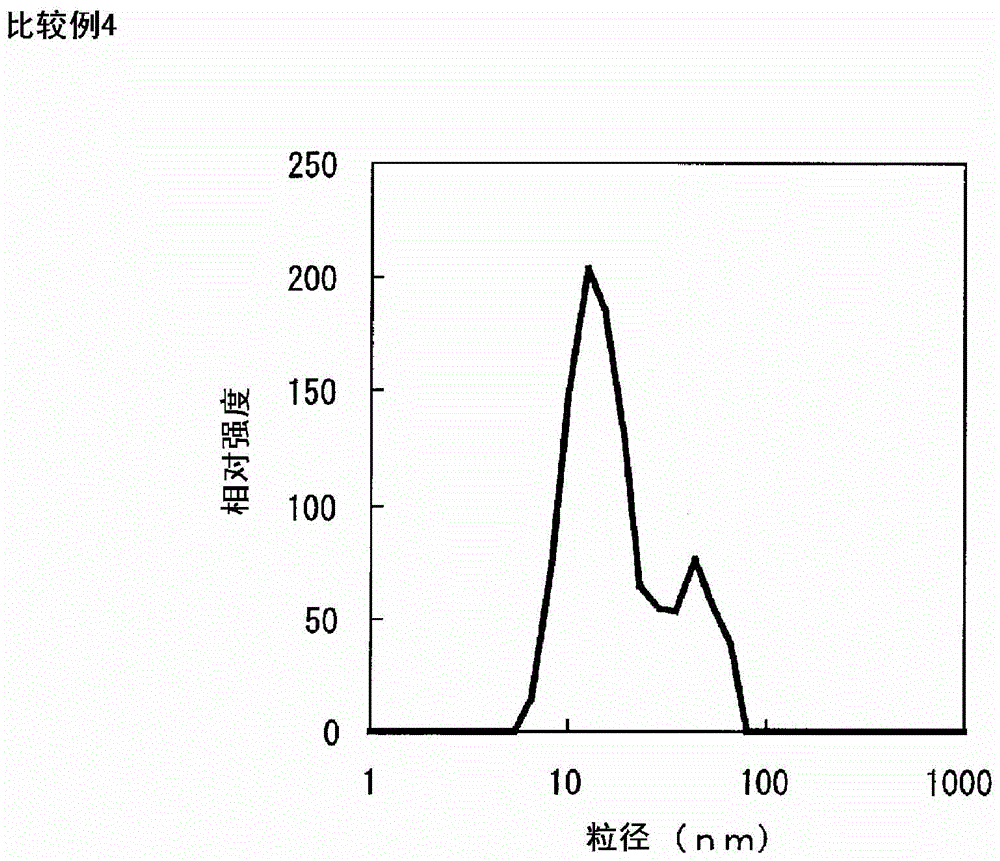

[0301] Hereinafter, the present invention will be described more specifically based on examples, but the present invention is not limited thereto. In addition, "part" in each Example and a comparative example means a "mass part" unless it specifically limits. As the measurement method and evaluation method, the following methods were used.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Weight-average Molecular Weight | aaaaa | aaaaa |

| Weight-average Molecular Weight | aaaaa | aaaaa |

Login to View More

Abstract

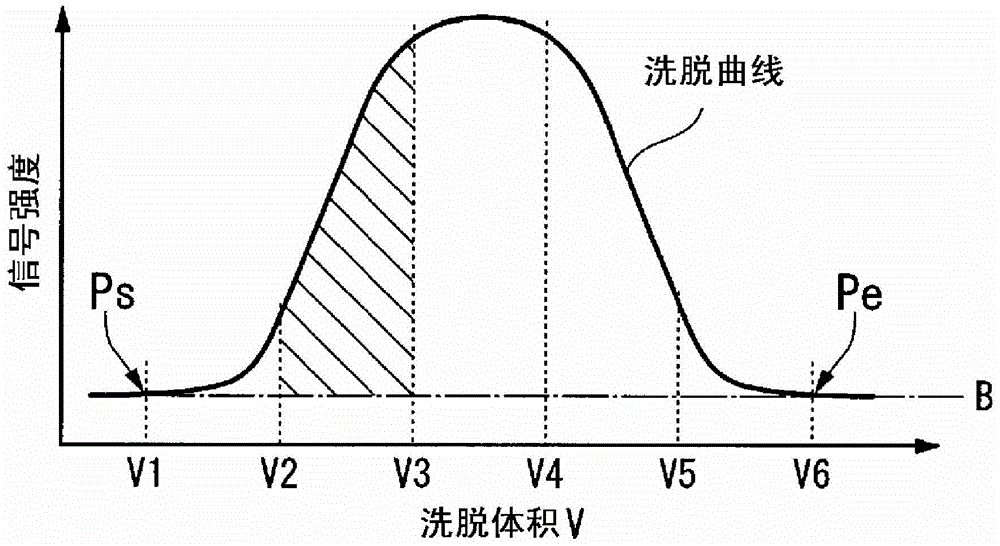

Provided is a copolymer for lithography, comprising monomer units that include oxygen leaving groups and monomer units that do not include oxygen leaving groups. Among five fractions in which an eluent showing peaks for copolymers in an elution curve obtained through gel permeation chromatography (GPC) is divided in order of elution so as to have equal volumes, when the proportions of monomer units that include oxygen leaving groups in the copolymers included in the first through fourth fractions, where the first is the earliest to elute, are N(v1)-N(v4) mol% and the proportions of monomer units that include oxygen leaving groups in the copolymers included in the total of the five fractions is Nave mol%, N(v1) / Nave is 1.01-1.09, and N(v2) / Nave, N(v3) / Nave, and N(v4) / Nave are each 0.95-1.05.

Description

technical field [0001] The present invention relates to a copolymer for lithography, a method for producing the copolymer for lithography, a resist composition using the copolymer for lithography, and a method for producing a patterned substrate using the resist composition. [0002] This application claims priority based on Japanese Patent Application No. 2012-048249 filed in Japan on March 5, 2012, and the content thereof is incorporated herein. Background technique [0003] In the manufacturing process of semiconductor elements, liquid crystal elements, and the like, the refinement of patterns formed by photolithography has rapidly progressed in recent years. As a method of refinement, there is shortening of the wavelength of irradiation light. [0004] Recently, KrF excimer laser (wavelength: 248nm) lithography technology has been introduced, and ArF excimer laser (wavelength: 193nm) lithography technology and EUV (wavelength: 13.5nm) lithography technology are being st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F220/12C08F2/00G03F7/039H01L21/027

CPCC08F220/20C08F2/00C08F220/18C08F220/12G03F7/0397C09D4/00C08F220/1808C08F24/00G03F7/004G03F7/20

Inventor 安田敦押切友也中条美帆

Owner MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com