A kind of paste creeper product and preparation method thereof

A creeper and paste technology, which is applied in the field of paste creeper products and its preparation, can solve the problems of high energy concentration, achieve high energy concentration, high digestibility, and improve the overall survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

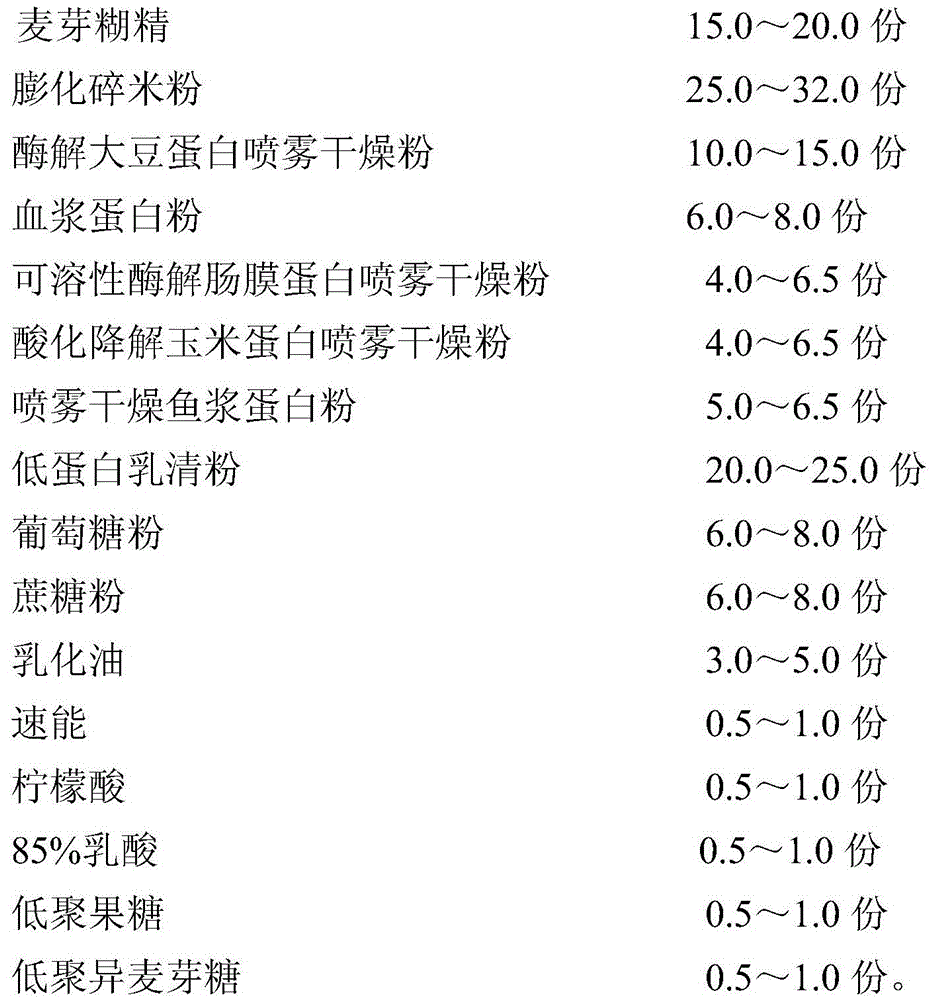

[0026] 1. Formula:

[0027]

[0028]

[0029] All the above-mentioned raw materials can be purchased in the raw material market.

[0030] Second, the operation process steps are as follows:

[0031] (1) Prepare intermediate material: spray the emulsified oil by the mass proportion into the puffed broken rice flour by the mass proportion to make the intermediate material;

[0032] (2) Raw material mixing: Pour the remaining other raw materials and the above-mentioned intermediate material into the twin-shaft paddle mixer according to the mass ratio, and mix evenly;

[0033] (3) Stir with water to form a paste: spray the uniformly mixed raw materials into water equivalent to 0.55 times the solid weight, and stir into a paste with a dough mixer;

[0034] (4) Tubular filling: the pasty material is measured and filled into a tubular finished product by a general toothpaste filling machine.

[0035] 3. Product composition testing:

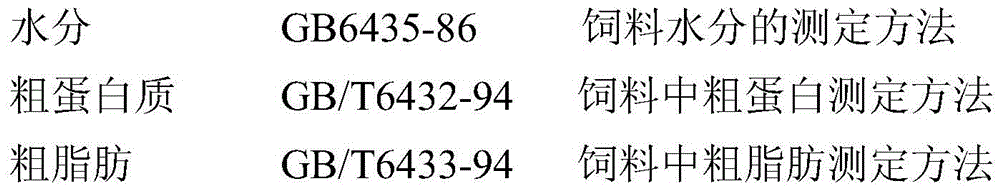

[0036] According to the detection method...

Embodiment 2

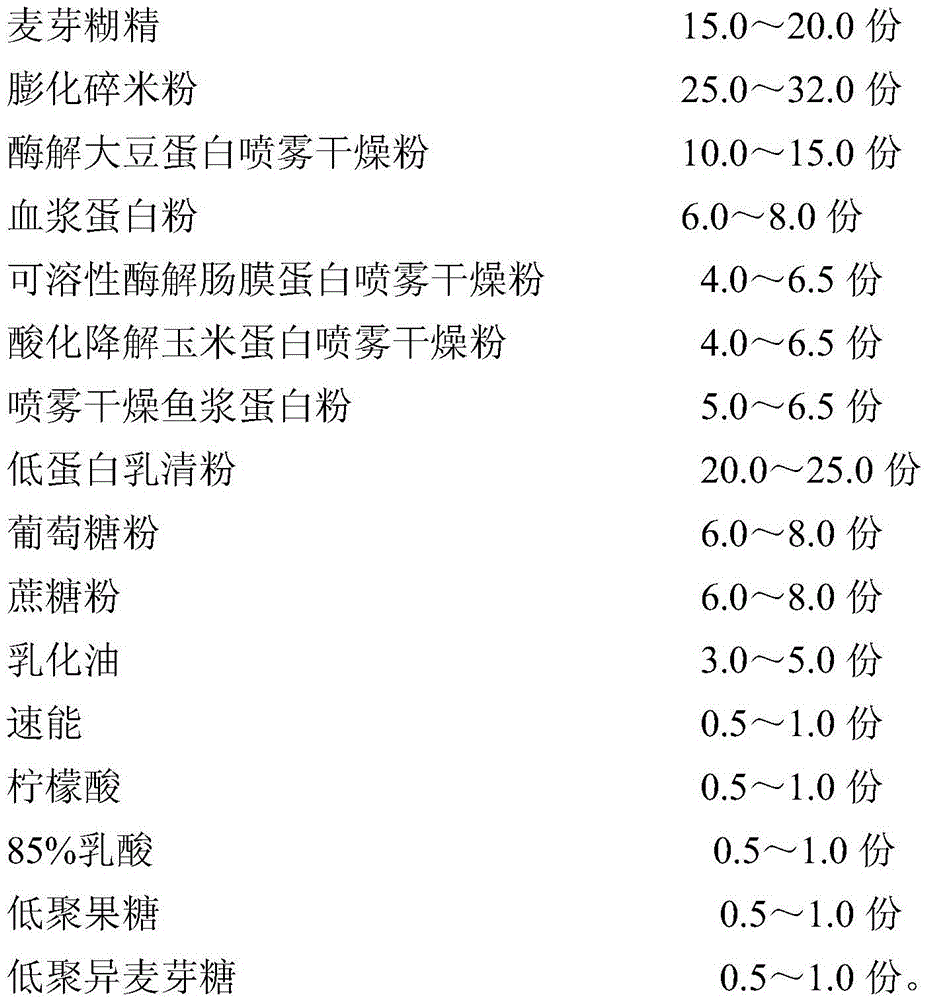

[0038] 1. Formula:

[0039]

[0040] All the above-mentioned raw materials can be purchased in the raw material market.

[0041] Second, the operation process steps are as follows:

[0042] (1) Prepare intermediate material: spray the emulsified oil by the mass proportion into the puffed broken rice flour by the mass proportion to make the intermediate material;

[0043] (2) Raw material mixing: Pour the remaining other raw materials and the above-mentioned intermediate material into the twin-shaft paddle mixer according to the mass ratio, and mix evenly;

[0044] (3) Stir with water to form a paste: spray the uniformly mixed raw materials into water equivalent to 0.55 times the solid weight, and stir into a paste with a dough mixer;

[0045] (4) Tubular filling: the pasty material is measured and filled into a tubular finished product by a general toothpaste filling machine.

[0046] 3. Product composition testing:

[0047] According to the detection method of the afor...

Embodiment 3

[0049] 1. Formula:

[0050]

[0051] All the above-mentioned raw materials can be purchased in the raw material market.

[0052] Second, the operation process steps are as follows:

[0053] (1) Prepare intermediate material: spray the emulsified oil by the mass proportion into the puffed broken rice flour by the mass proportion to make the intermediate material;

[0054] (2) Raw material mixing: Pour the remaining other raw materials and the above-mentioned intermediate material into the twin-shaft paddle mixer according to the mass ratio, and mix evenly;

[0055] (3) Stir with water to form a paste: spray the uniformly mixed raw materials into water equivalent to 0.55 times the solid weight, and stir into a paste with a dough mixer;

[0056] (4) Tubular filling: the pasty material is measured and filled into a tubular finished product by a general toothpaste filling machine.

[0057] 3. Product composition testing:

[0058] According to the detection method of the afor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com