Modification and preparation methods based on IRMOF-3 functional material

An IRMOF-3, functional material technology, applied in the field of material chemistry, can solve the problem that MOFs materials cannot meet the harsh requirements of materials, and achieve the effects of easy operation, simple characterization method and mild processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the embodiments.

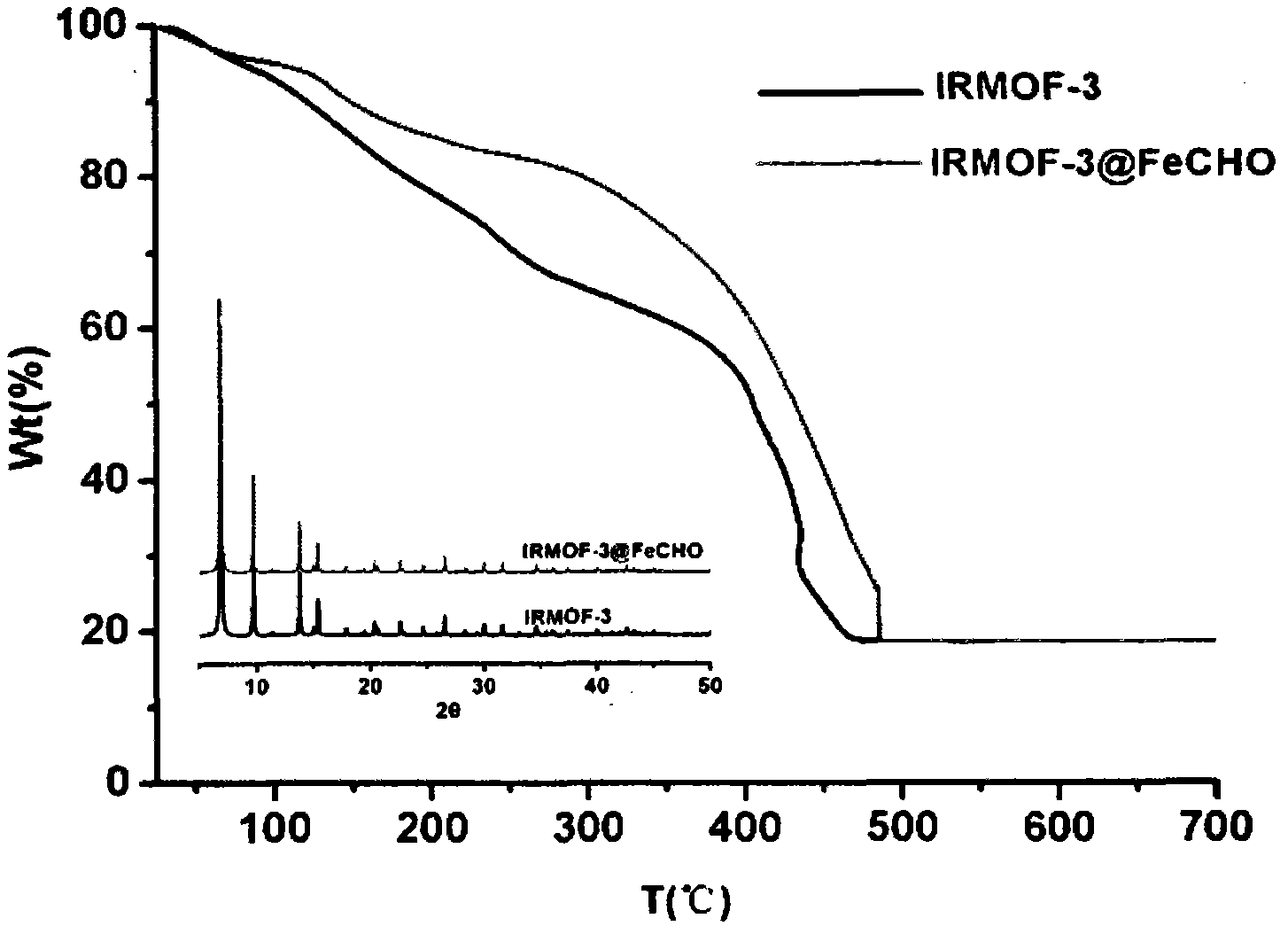

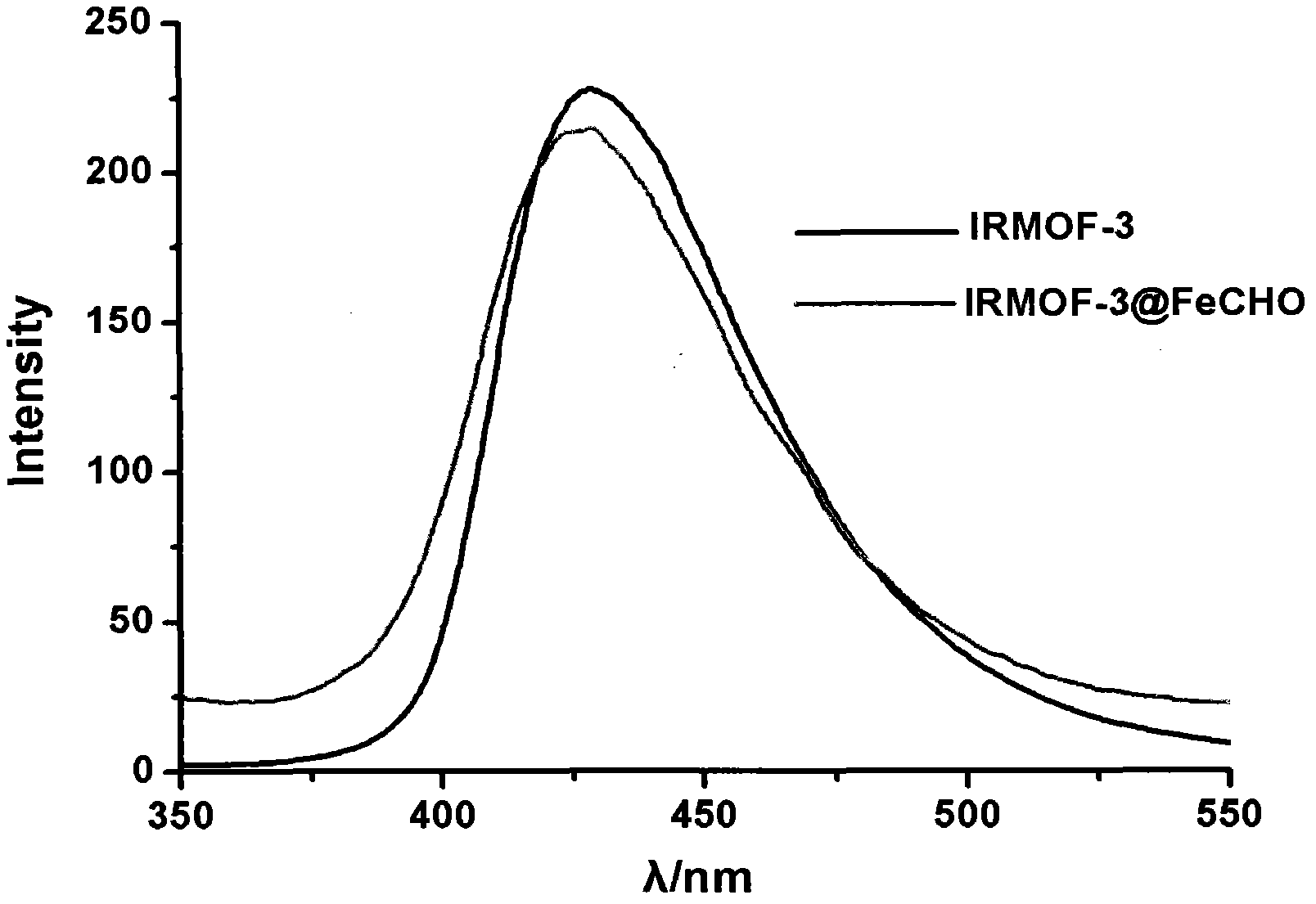

[0017] Divide the prepared IRMOF-3 functional material into several parts with an amount of 9mg-15mg, pretreat it with 5-10ml dichloromethane for 3-7 days, and then combine 1-10mg of the guest molecule ferrocene aldehyde with the treated Put the raw material in 5-10ml of dichloromethane for 1-10 days, and dry the material under reduced pressure for 1-2 days to remove the guest molecules remaining on the surface of the material. Observation in the electron microscope shows that IRMOF-3 is changed from the original Amber changes to black. Elemental analysis, thermogravimetric analysis, fluorescence analysis, X-ray powder diffraction (PXRD) analysis and characterization of the material found that about 2.87 ferrocene aldehyde molecules entered the IRMOF-3 porous material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com