Inorganic polyurethane heat insulation veneering decoration system

A polyurethane and inorganic technology, applied in thermal insulation, building components, fire protection, etc., can solve problems such as difficult control of construction flatness, lack of scientific connection, cracking of insulation layer, etc., to achieve rich performance, ensure overall quality, and reduce self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

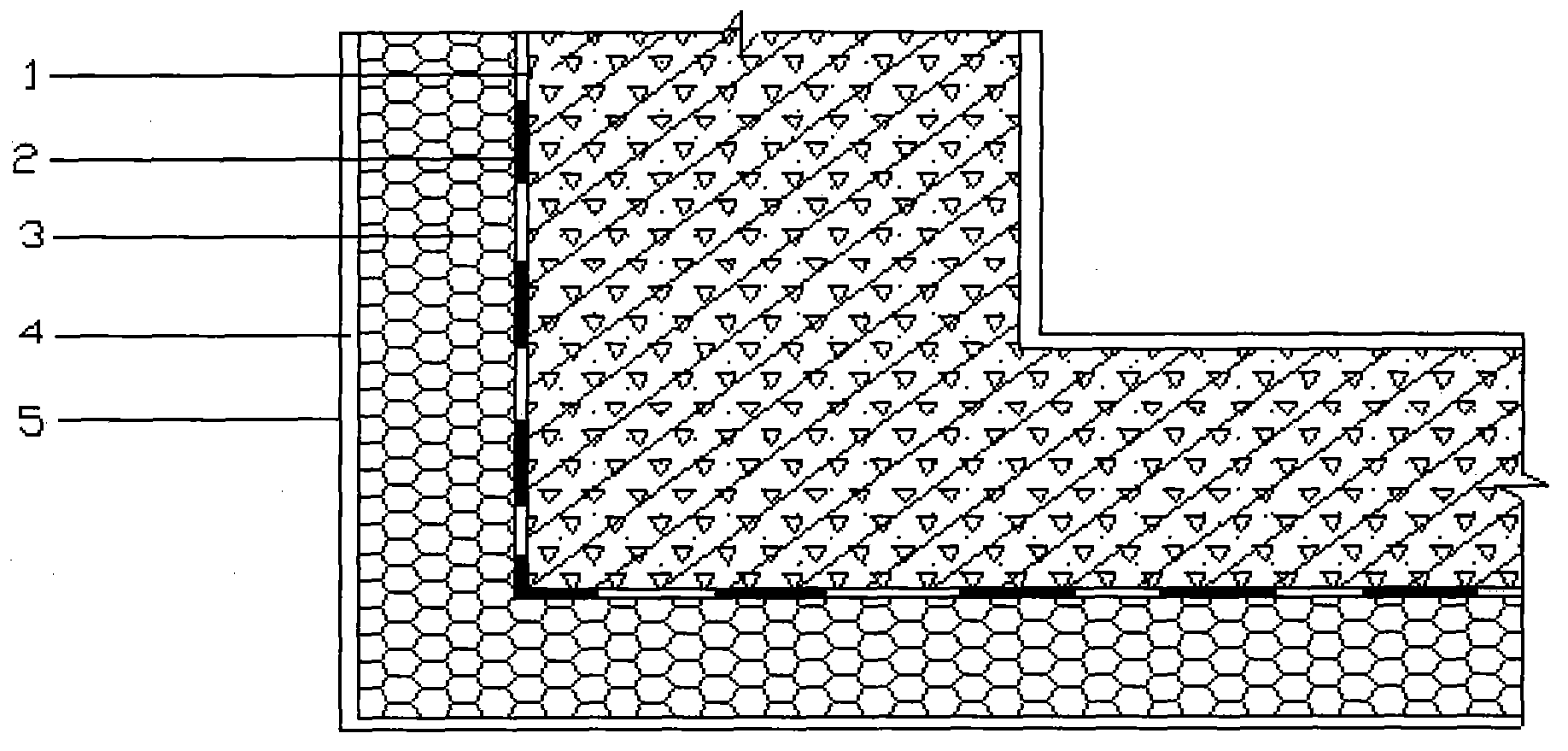

[0026] see figure 1 , A new type of inorganic polyurethane thermal insulation veneer decoration system, the system includes a bottom adhesive layer 2, a thermal insulation and fireproof board 3, a surface layer adhesive layer 4, and a protective finishing layer 5 from the outer wall base surface 1 to the outside.

[0027] The bonding layer 2 is composed of strip-shaped polymer bonding mortar located in the surrounding frame of the thermal insulation and fireproof layer 3 and a dot-shaped polymer bonding mortar in the middle, with a thickness of 5-10 mm.

[0028] The polymer bonding mortar is a general bonding mortar in construction.

[0029] The thermal insulation and fireproof board 3 is a rigid foam polyurethane PUR or PIR board with a thickness of 20-200mm.

[0030] The surface layer adhesive layer 4 is configured by modified polyurethane adhesive or polymer emulsion and heavy calcium carbonate, and has a thickness of 0.5-1.5 mm.

[0031] The protective finishing layer 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com