Preparation method of chili sauce

A technology of oily chili and chili, applied in the field of preparation of oily chili

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

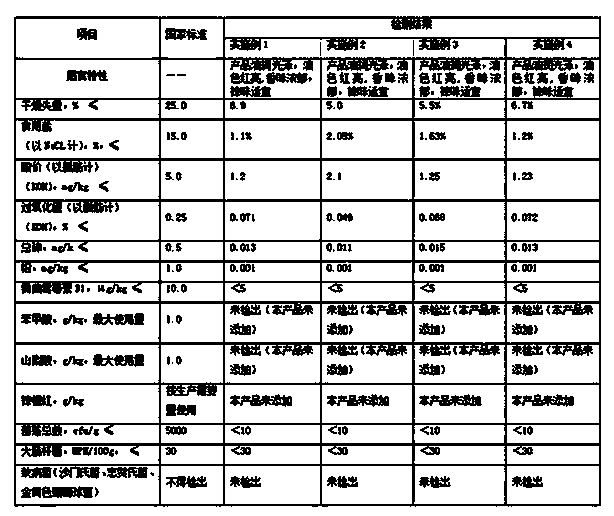

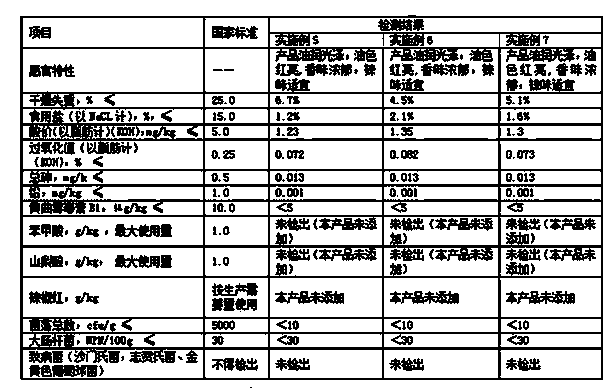

Examples

Embodiment 1

[0024] (1) Preparation of pepper raw materials: take mature fresh peppers with bullet-heads without worms and mildew, clean them, and twist them into pepper pieces with a length and width of 5mm-8mm;

[0025] (2) Stir-frying: Weigh 20 parts of rapeseed blended oil, when the oil temperature rises to 180°C, add 5 parts of bean paste and 35 parts of peppers processed in step (1) and fry for 5 minutes, then add 0.1 parts of ginger, Stir-fry 0.1 part of green onion and 0.4 part of garlic for 5 minutes, then add 2 parts of sweet noodle sauce, 0.1 part of monosodium glutamate, 0.1 part of vinegar, and 1 part of salt, and fry until the temperature of the material reaches 120°C. , and stir evenly to get the fried chili oil;

[0026] (3) Packaging: Clean the undamaged glass bottle, steam sterilize it, and immediately fill the fried pepper in step (2) into the sterilized glass bottle at a speed of 5kg / min. After the filling is completed The finished product is obtained by sealing under ...

Embodiment 2

[0029] (1) Preparation of chili raw materials: take mature, worm-free and mildew-free steamed bullet-head dried chili peppers, clean them and twist into chili pieces with a length and width of 5mm-8mm;

[0030] (2) Stir-frying: Weigh 30 parts of rapeseed blended oil, and when the oil temperature rises to 200°C, add 10 parts of bean paste and 40 parts of peppers treated in step (1) and fry for 8 minutes, then add 0.3 parts of ginger, 0.3 Stir-fry 1 portion of shallot and 0.6 portion of garlic for 8 minutes, then add 5 portions of sweet noodle sauce, 0.5 portion of monosodium glutamate, 0.3 portion of vinegar, and 2 portions of salt, and fry until the temperature of the material reaches 125°C. Stir well to get fried chili oil;

[0031] (3) Packing: Clean the undamaged glass bottle, steam sterilize it, and immediately fill the fried pepper in step (2) into the sterilized glass bottle at a speed of 6kg / min. The finished product is obtained by sealing under vacuum conditions.

[...

Embodiment 3

[0034] (1) Preparation of pepper raw materials: take mature fresh peppers with bullet-heads without worms and mildew, clean them and twist them into pepper pieces with a length and width of 5mm-8mm;

[0035] (2) Stir-frying: Weigh 25 parts of rapeseed blended oil. When the oil temperature rises to 190°C, add 8 parts of bean paste and 38 parts of peppers processed in step (1). After frying for 7 minutes, add 0.2 parts of ginger, Stir-fry 0.2 parts of green onions and 0.5 parts of garlic for 6 minutes, then add 3 parts of sweet noodle sauce, 0.3 parts of monosodium glutamate, 0.2 parts of vinegar, and 1.5 parts of salt, and fry until the temperature of the material reaches 123°C. , Stir evenly to get fried chili oil;

[0036] (3) Packaging: Clean the undamaged glass bottle, steam sterilize it, and immediately fill the fried pepper in step (2) into the sterilized glass bottle at a speed of 5kg / min. After the filling is completed The finished product is obtained by sealing under va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com