Oil chili and its preparation method

A production method and oil pepper technology, applied in food science and other directions, can solve problems affecting product production and sensory quality, and achieve the effects of promoting appetite, bright red color, and suitable spiciness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

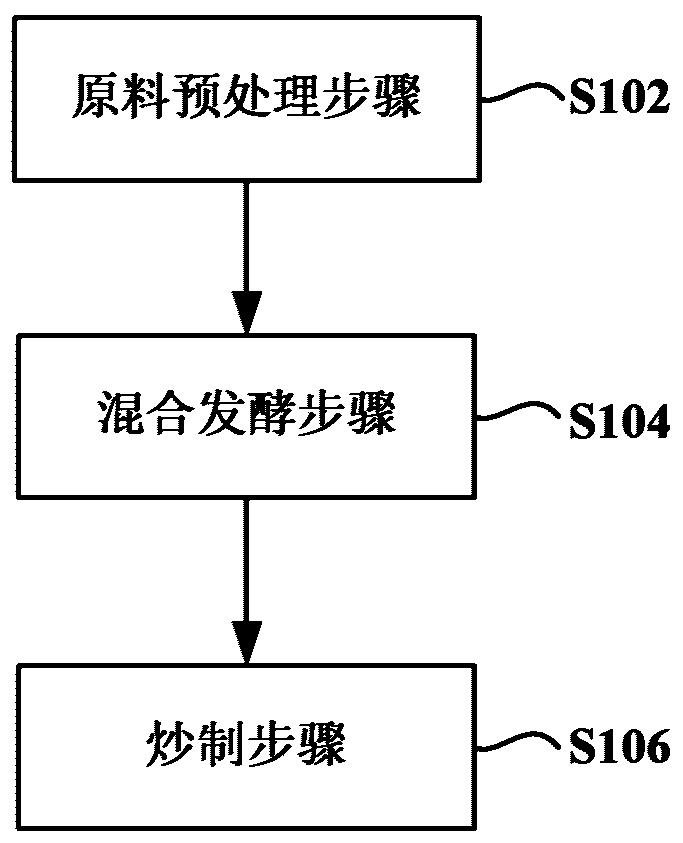

Method used

Image

Examples

Embodiment 1

[0056] Weigh raw materials according to the following weights:

[0057] 100g fresh red pepper, 80g rapeseed oil, 60g tomato, 30g garlic, 10g ginger, 15g minced meat, 8g salt, 10g white wine, 15g rock sugar, 10g wheat sauce, 6g monosodium glutamate.

[0058] (1) Raw material pretreatment steps:

[0059] a. Remove the stalks of the bright red peppers, wash them, drain the water, crush them to a size below 8mm to form raw chili sauce, and set aside;

[0060] b. Peel the garlic and ginger, mince until 2-3mm granular, and set aside;

[0061] c. Wash the tomatoes, drain the water, chop them until they are 2-3mm granular, and set aside;

[0062] d. Heat the rapeseed oil to remove the smell of raw oil, let it cool, and set aside.

[0063] (2) mixed fermentation step:

[0064] Mix the raw chili sauce, garlic, ginger, salt, and rock sugar obtained in the raw material pretreatment step, then add white wine and 4g of rapeseed oil to make oily chili raw material, put it in an altar and...

Embodiment 2

[0068] Weigh raw materials according to the following weights:

[0069] 100g fresh red pepper, 70g rapeseed oil, 50g tomato, 20g garlic, 20g ginger, 4g salt, 8g white wine, 10g rock sugar, 5g wheat sauce, 7g monosodium glutamate.

[0070] (1) raw material pretreatment step: same as embodiment 1.

[0071] (2) mixed fermentation step:

[0072] Mix the raw chili sauce, garlic granules, ginger granules, salt, and rock sugar obtained in the raw material pretreatment step, then add white wine and 5.6g of rapeseed oil to make oily chili raw material, put it in an altar and ferment it. Make chili sauce raw material, put it in an altar and ferment it for about 10 days, and set it aside.

[0073] (3) Frying steps:

[0074] Heat the remaining 64.4g rapeseed oil to 80°C again, add the fermented oil chili raw material and tomato dices to the rapeseed oil, and stir-fry evenly at 100°C for 1.5 hours; Heat to 120°C, add wheat sauce and monosodium glutamate to taste, and let it cool natura...

Embodiment 3

[0076] Weigh raw materials according to the following weights:

[0077] 100g fresh red pepper, 50g rapeseed oil, 40g tomato, 10g garlic, 10g ginger, 6g salt, 4g white wine, 8g rock sugar, 1g wheat sauce, 5g monosodium glutamate.

[0078] (1) raw material pretreatment step: same as embodiment 1.

[0079] (2) mixed fermentation step:

[0080] Mix the raw chili sauce, garlic, ginger, salt, and rock sugar obtained in the raw material pretreatment step, then add white wine and 5g of rapeseed oil to make oily chili raw material, put it in an altar and ferment it into Chili sauce raw materials, put in jars and ferment for about 10 days, set aside.

[0081] (3) Frying steps:

[0082] Heat the remaining 45g of rapeseed oil to 80°C again after removing the oily smell, add the fermented pepper raw material and tomato dices to the rapeseed oil, fry evenly at 100°C for 1.5 hours; To 120°C, add wheat sauce and monosodium glutamate to taste, and let it cool naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com