Carbon-wrapped polyhedron silver nano-particle and controllable self-assembly preparation method thereof

A technology of silver nanoparticles and nanoparticles, which is applied in the field of shape control and self-assembly preparation of noble metal nanoparticles, to achieve uniform size distribution, easy operation, and improved chemical reactivity and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of Ag / C core-shell composite particles: Dissolve 1.25g of glucose, 0.50g of PVP and 0.028g of silver nitrate in 100ml of deionized water in turn to obtain a reaction mixture solution, and ultrasonically for 20 minutes to completely dissolve the solid and PVP. The concentrations of glucose, PVP and silver nitrate in the solution were 0.07M, 0.04M and 0.25mM, respectively. 40ml of the mixed solution was transferred to a 50ml reaction kettle, and reacted at a constant temperature of 180°C for 6 hours. The reaction kettle was naturally cooled to room temperature, and the product was repeatedly centrifuged and washed, and finally vacuumed or N 2 Dry in an oven at 50±10°C under a protective atmosphere.

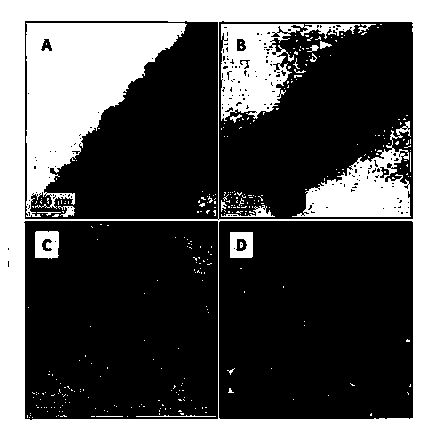

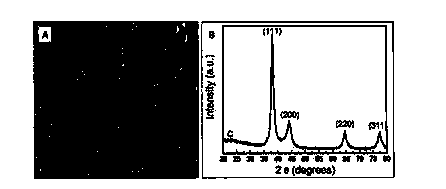

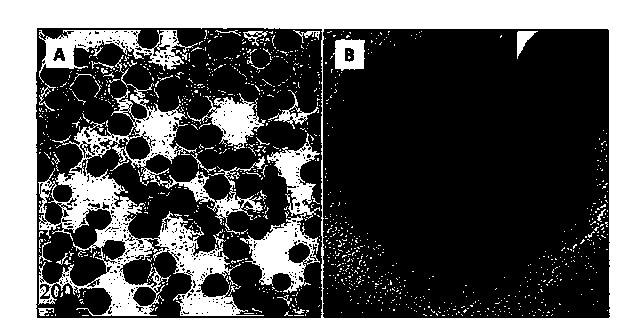

[0034]figure 1 (A) is the SEM picture of the product prepared in Example 1, it can be seen that a large number of monodisperse nanoparticles are formed. As can be seen from the high magnification SEM inset, the nanoparticles present a uniform polyhedral morpholo...

Embodiment 2

[0037] The reaction time was changed to 1 hour. Other conditions are with embodiment 1.

Embodiment 3

[0039] The reaction time was changed to 2 hours. Other conditions are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com