Welding method for temperature pipe and reheat cooling section pipe

A technology of reheating and cold section and welding method, which is applied in the field of steel welding, can solve problems such as joint failure, creep resistance, durable strength and plasticity decline, and achieve good reliability, satisfactory weld performance and good crack resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

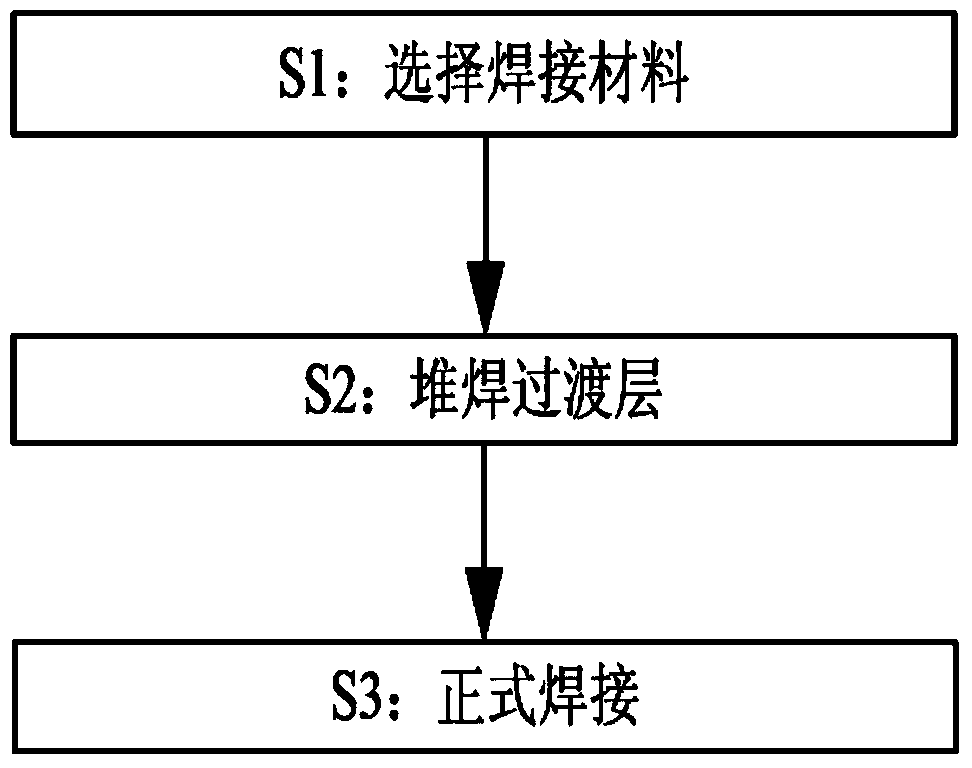

[0029] Such as figure 1 As shown, preferably, this embodiment provides a method for welding a temperature tube and a reheated cold section tube, and the steps include:

[0030] S1, select welding material:

[0031] Choose high chromium nickel austenitic stainless steel welding wire or nickel-based welding wire as welding material. Now choose Inconel 82 welding wire, the chemical composition of the welding wire is shown in Table 1.

[0032] Table 1 Chemical composition of welding wire:

[0033] Welding wire NiC Mn Nb SiCuCr Ti S, P Inconel 82 670.103.02.50.50.25200.750.02

[0034] The welding material is Inconel 82 welding wire. The Inconel 82 welding wire includes 67% Ni, 0.1% C, 3.0% Mn, 2.5% Nb, 0.5% Si, 0.25% Cu, 20% Cr, 0.75% Ti, 0.02% S and P.

[0035] Before welding, clean the temperature tube and the reheating cold section tube: before the weldment is assembled, the oil, paint, rust, scale, etc. on the surface of the groove and the inner and outer walls of the adjacent bas...

Embodiment 2

[0049] S1, select welding material:

[0050] Choose high chromium nickel austenitic stainless steel welding wire or nickel-based welding wire as welding material. Now choose Inconel 82 welding wire

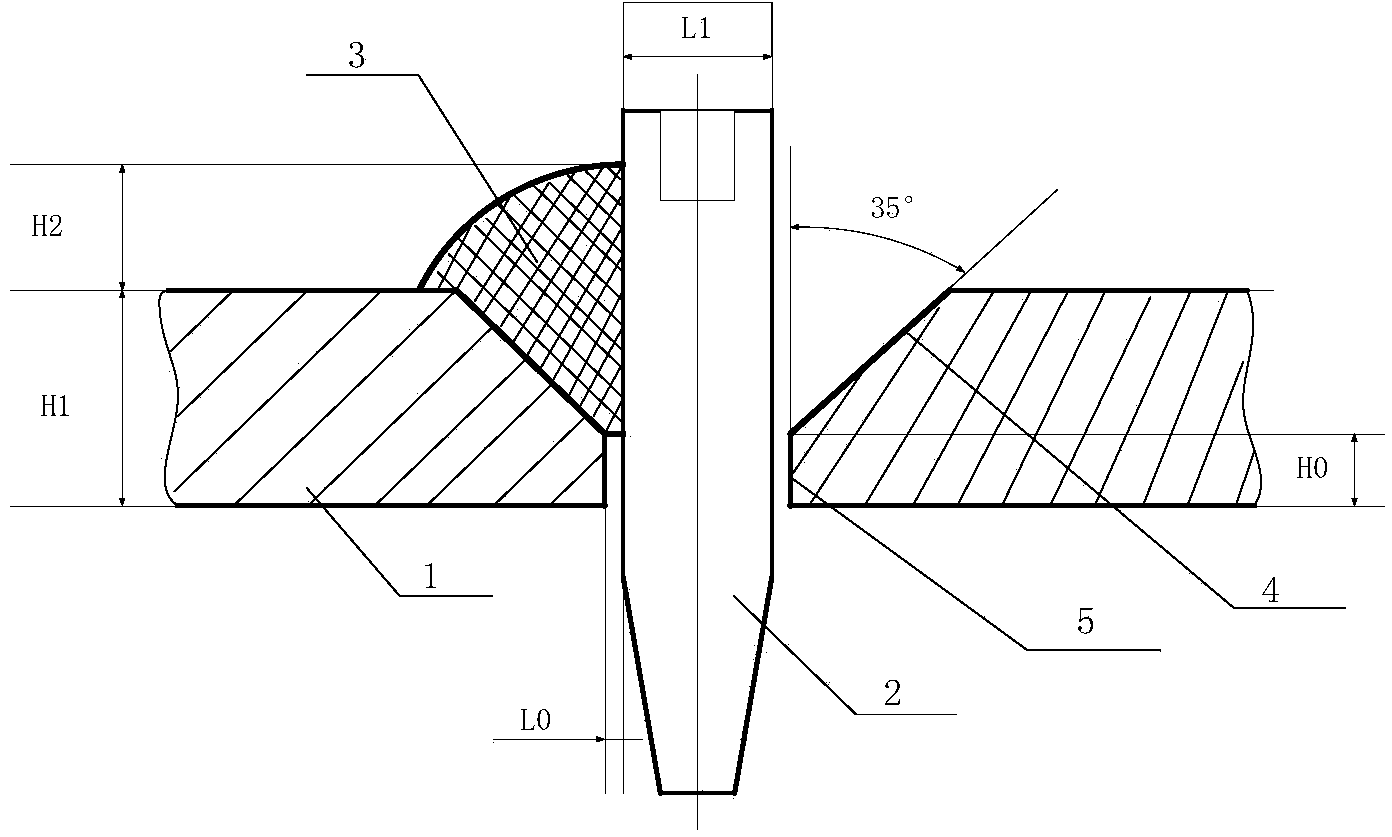

[0051] S2, over-surfacing layer:

[0052] The transition layer is welded on the base material side of the reheated cold section pipe with the welding material in step 1, and the transition layer includes five layers.

[0053] S3, formal welding:

[0054] Find the welding center of the reheated cold section tube and the temperature tube, and weld the temperature tube and the reheated cold section tube by electric welding with the welding material in step 1.

[0055] The welding method in step S3 is manual argon tungsten arc welding; and the welding voltage range is 25V, the welding current is direct current, the current is 90A, and the welding speed is 80mm / min; in the welding method of step three, the first layer welding speed 60mm / min, the second layer welding speed is 65mm / min, the third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com