Ultrafiltration membrane aeration plate and method thereof

A technology of ultrafiltration membrane and aeration plate, applied in the direction of aerobic process treatment, sustainable biological treatment, etc., can solve the problems of low mass transfer rate and large aperture of aerator, so as to improve the gas-liquid mass transfer rate, strong Economical efficiency and the effect of improving the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

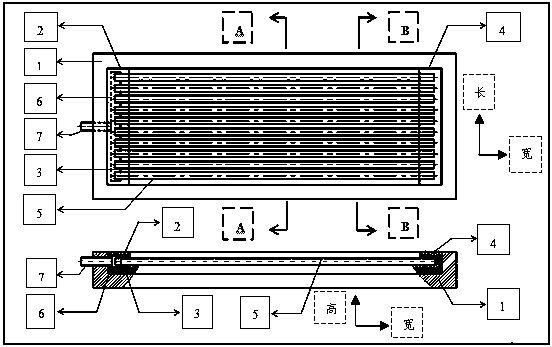

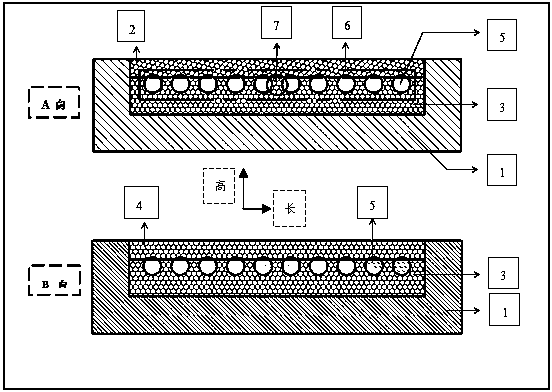

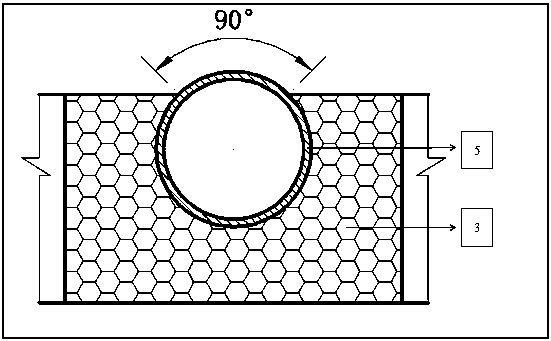

[0021] like figure 1 , 2 As shown in and 3, a base 1 is provided at the bottom of an ultrafiltration membrane aeration plate, and after the top of the base 1 is grooved, the starting glue 2, the main glue 3 and the end glue 4 are filled on the left side, the center and the right side respectively, After laying the ultrafiltration membrane 5, solidify as a whole. The top of the main glue 3 is lower than the top of the base 1, submerging and sealing 75% of the circumference of the ultrafiltration membrane 5. The top of the starting glue 2 is flush with the top of the base 1 to fix the starting end of the ultrafiltration membrane 5 . The starting end of the ultrafiltration membrane 5 is opened to the air distribution chamber 6 in the rubber 2 at the beginning end, and the air distribution chamber 6 is connected to the gas supply device through the air inlet pipe 7 . The top of the end glue 4 is flush with the top of the base 1 to fix and seal the end of the ultrafiltration mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com