Multi-stage serial modular domestic wastewater treatment system and domestic wastewater treatment method

A technology for domestic sewage and treatment systems, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problems of high operation and maintenance costs, complex technological processes, and low treatment efficiency. , to achieve the effect of convenient construction, low cost and improving the effect of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

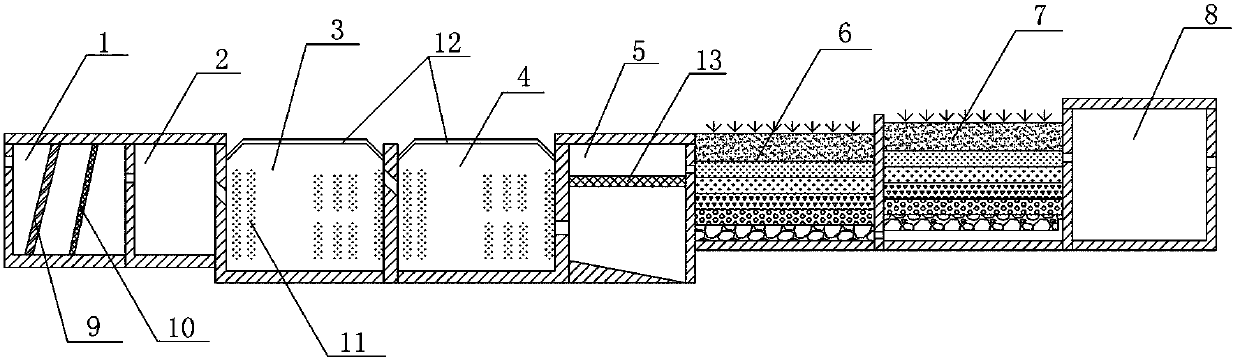

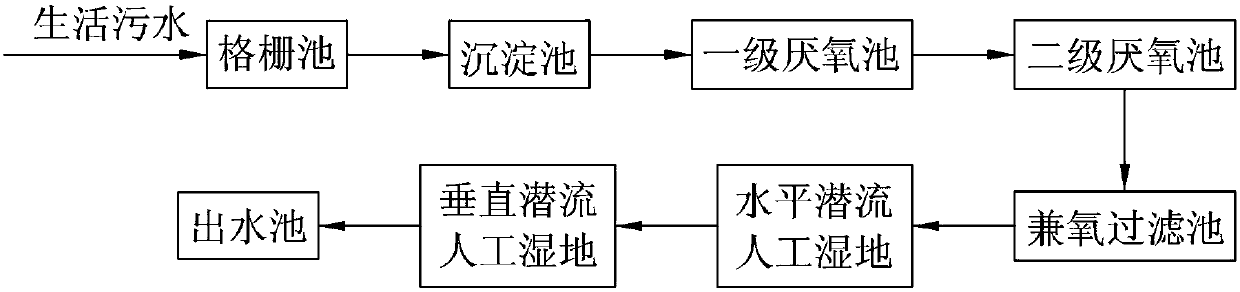

[0032] Embodiment 1: A multi-stage serial modularized domestic sewage treatment system, including grid tank 1, sedimentation tank 2, anaerobic tank, aerobic filter tank 5, horizontal subsurface flow constructed wetland 6, and vertical subsurface flow constructed wetland 7 in series in sequence And effluent pool 8, grid pool 1 is provided with sewage water inlet, and effluent pool 8 is provided with clean water outlet; In grid pool 1, be provided with grid 9 and grease trap 10; At the top of anaerobic pool, be provided with The self-regulating biogas anaerobic fermentation cover 12 is hung with three-dimensional elastic packing 11 in the anaerobic tank; There is a filter screen 13; the bottom of the vertical subsurface flow constructed wetland 7 is provided with a water distribution pipe network connected to the water outlet of the horizontal subsurface flow constructed wetland 6.

[0033] In the grid pool 1, the grid spacing is 2.5mm, which is used to intercept and remove larg...

Embodiment 2

[0037] Embodiment 2: The difference from Example 1 is that, by weight percentage, the red loam layer contains 3-12% of modified attapulgite, and the preparation method of this modified attapulgite is as follows:

[0038] (1) Pretreatment: Grind attapulgite and pass through a 20-100 mesh sieve, then calcinate at 200°C for 3-5 hours, soak in deionized water for 20-30 hours, wash several times until the washing water is clarified, and then dry it for later use ;

[0039] (2) Activation modification: Slowly dissolve a certain amount of chitosan with HAc solution with a volume fraction of 2-4%. A certain amount of the chitosan colloidal solution is mixed and stirred into a paste, and the amount of the chitosan colloidal solution is used so that the attapulgite is fully infiltrated, and then the obtained paste is dried at 105° C. to complete.

Embodiment 3

[0040] Embodiment 3: A multi-stage serial modularized domestic sewage treatment system. The difference from Embodiment 1 is that the anaerobic tank is a first-level anaerobic tank 3 and a second-level anaerobic tank 4 connected in series. The filler 11 is provided with polyvinyl alcohol-sodium alginate gel balls and porous spherical suspension fillers. The preparation method of the polyvinyl alcohol-sodium alginate gel ball is as follows: polyvinyl alcohol and sodium alginate with a mass ratio of 9:1 are prepared by a solution blending method.

[0041] Using two-stage anaerobic tanks in series to treat sewage can effectively improve the anaerobic digestion of organic matter. Polyvinyl alcohol-sodium alginate gel balls and porous spherical suspension fillers are added on the three-dimensional elastic filler. Polyvinyl alcohol (PVA)-sodium alginate (SA) gel balls are prepared by solution blending method, and the mixing ratio is: m(PVA):m(SA)=9:1. The diameter of the polyvinyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com