Method for extracting active substances for fertilizers from algae

A technology of active substances and algae, applied in the field of biotechnology, can solve the problems of easy precipitation of alginic acid, complicated technology, and large damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

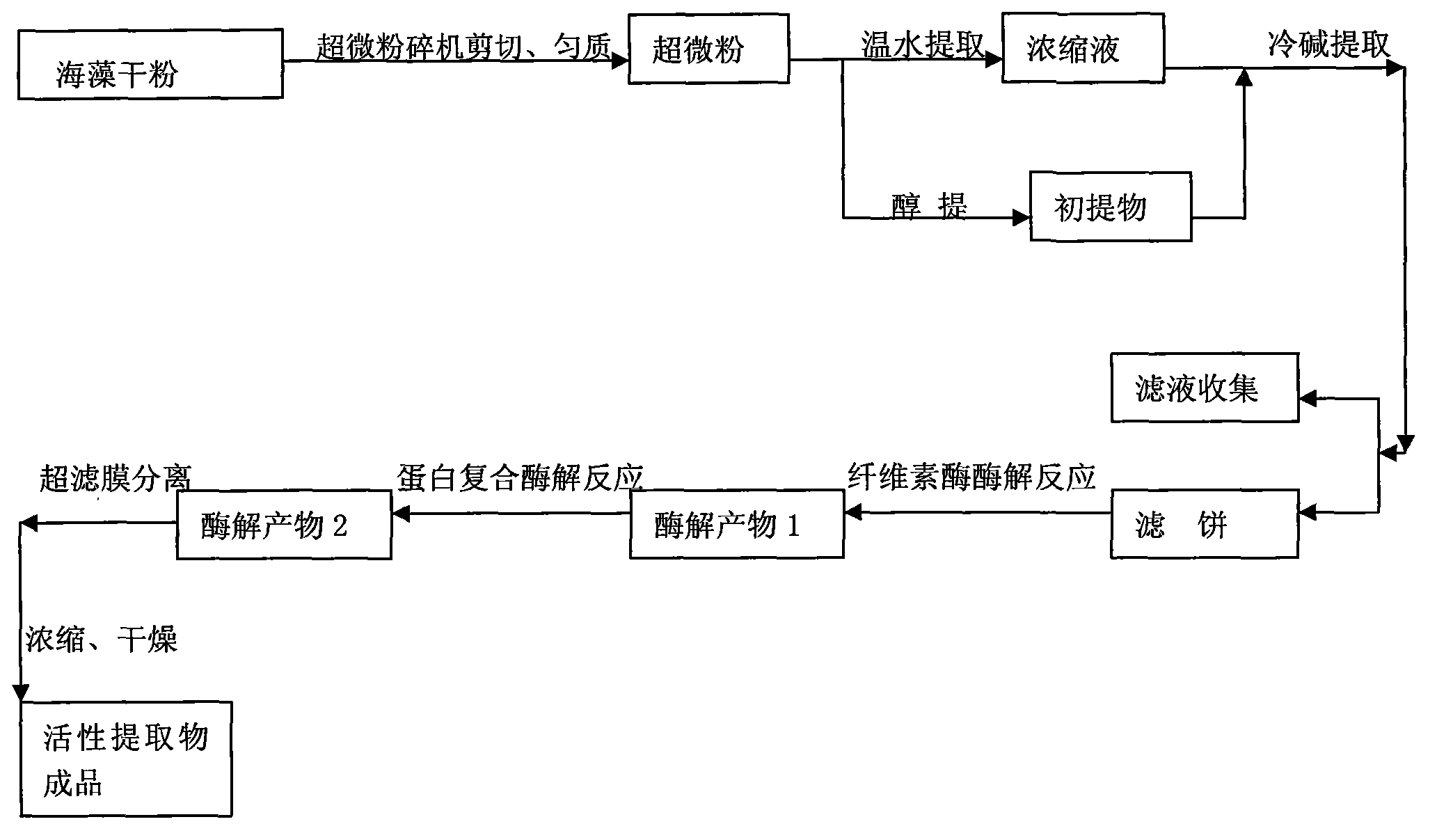

Image

Examples

Embodiment 1

[0011] Step 1: After mixing the dry seaweed powder and water with a pH close to neutral at a ratio of 1:20 to 1:10, enter the superfine pulverizer to shear and homogenize.

[0012] The second step: the homogenized sample is refluxed under reduced pressure, and the temperature is controlled at 50°C-70°C for water extraction; after water extraction, the extract is concentrated to below the original volume of 2096. The initial extract is placed in 40 times of 11% alkaline solution, extracted at 2-6°C for 10 hours, adjusted to a pH value of about 7.0 with acetic acid, centrifuged after the extraction is completed, and the filtrate is collected. The filtrate contains seaweed polysaccharides with small molecular weight. The active substance can be obtained by desalination under reduced pressure. The filter cake enters the next step of processing.

[0013] Step 3: After the filter cake is homogenized in water at a ratio of 1:10, it is put into a biochemical reaction tank for enzymol...

Embodiment 2

[0016] Step 1: After mixing the dry seaweed powder and water with a pH close to neutral at a ratio of 1:20 to 1:10, enter the superfine pulverizer to shear and homogenize.

[0017] The second step: the homogenized sample is concentrated under reduced pressure, the volume is reduced to 10% of the original volume, 9 times the volume of ethanol is added, refluxed for 3 hours, filtered, the filtrate is collected, the filtrate is concentrated to a paste under pressure, and the primary extraction of green algae is obtained. things. The initial extract is placed in 40 times of 11% alkaline solution, extracted at 2-6°C for 10 hours, adjusted to a pH value of about 7.0 with acetic acid, centrifuged after the extraction is completed, and the filtrate is collected. The filtrate contains seaweed polysaccharides with small molecular weight. The active substance can be obtained by desalination under reduced pressure. The filter cake enters the next step of processing.

[0018] Step 3: Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com