Aldehyde/benzene-removal ecological putty and manufacturing method thereof

An ecological and putty technology, applied in the field of building decoration materials, can solve the problems of not being able to meet daily needs, not having other functions, polluting indoor air, etc., and achieve the effects of enhancing human immune function, good leveling, and fresh air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

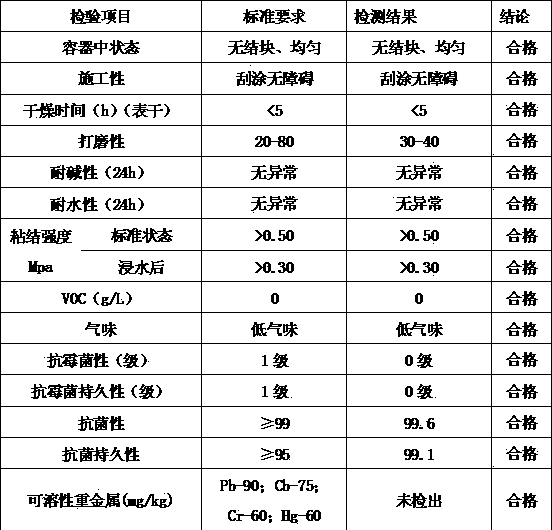

Image

Examples

Embodiment 1

[0025] An ecological putty for removing aldehyde and benzene, whose raw materials are composed of the following parts by weight: 200kg of water, 70kg of heavy calcium carbonate powder, 16kg of ash calcium powder, 15v of white cement, 2.5kg of HPMC, 6kg of negative ion natural mineral powder, Brightener 2kg, Toosendan 3kg, Honeysuckle 2kg, Tripterygium wilfordii 2kg, Capillaris 1kg, Clove Basil 1.5kg, Angelica dahurica 2kg, Ambergris 1kg, the negative ion natural mineral powder is tourmaline, lanthanide rare earth compound salt A mixture of titanium dioxide and titanium oxide in a weight ratio of 3:4:3, wherein tourmaline is a mixture of magnesium tourmaline and lithium tourmaline in a weight ratio of 7:3.

[0026] Specifically, the fineness of the negative ion natural mineral powder is 8000 mesh; the viscosity of the HPMC is 80000mPa·s; the fineness particle size of the ground calcium carbonate powder is 700; the fineness of the gray calcium powder The particle size is 700 mes...

Embodiment 2

[0031] An ecological putty for removing aldehyde and benzene, whose raw materials are composed of the following parts by weight: 280kg of water, 55kg of heavy calcium carbonate powder, 25kg of gray calcium powder, 10kg of white cement, 4kg of HPMC, 3kg of negative ion natural mineral powder, and whitening agent 2.5kg, Toosendan 2kg, Honeysuckle 3kg, Tripterygium wilfordii 1kg, Capillaris 2kg, Clove Basil 1kg, Angelica dahurica 3kg, Ambergris 0.5kg, described negative ion natural mineral powder is tourmaline, lanthanide rare earth compound salts and A mixture of titanium oxide in a weight ratio of 3:4:3, wherein tourmaline is a mixture of magnesium tourmaline and lithium tourmaline in a weight ratio of 7:3.

[0032] Specifically, the fineness of the negative ion natural mineral powder is 6000 mesh; the viscosity of the HPMC is 100000mPa·s; the fineness particle diameter of the heavy calcium carbonate powder is 1200 mesh; The fineness particle diameter is 1200 meshes; the finene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Fine particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com