High-birefringence nematic phase liquid crystal material and application thereof

A technology of liquid crystal materials and nematic phases, applied in liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of not meeting the electro-optical performance indicators of PDLC films at the same time, and achieve the improvement of off-state scattering intensity and electric field response speed, wide Use temperature range to meet the effect of building energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

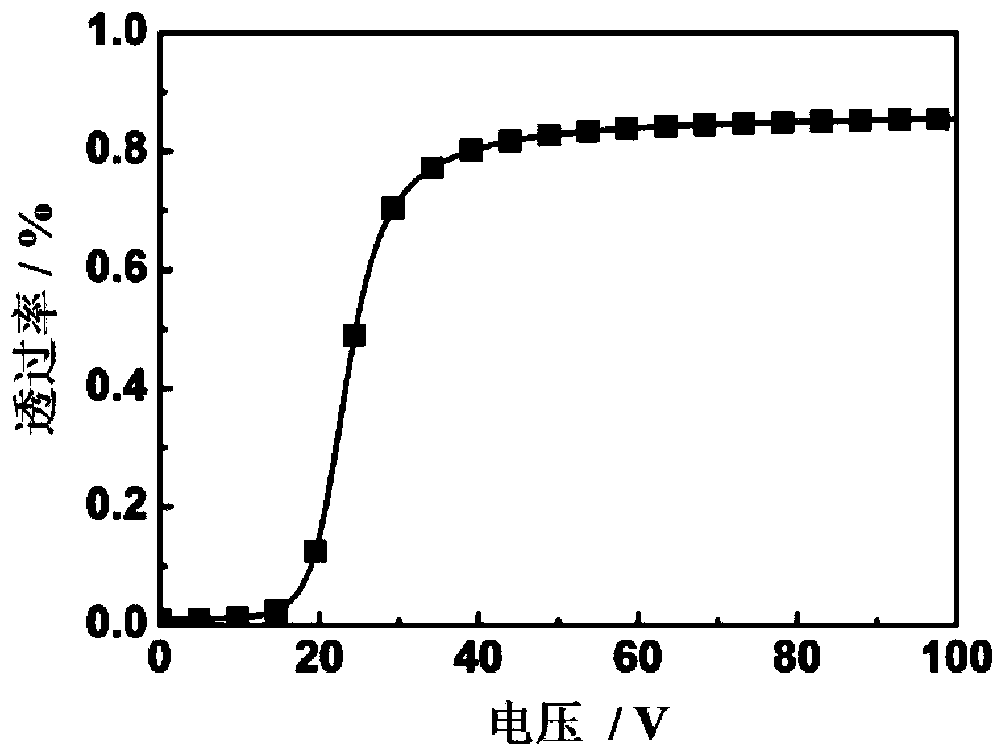

[0052] Prepare the nematic liquid crystal mixture according to the corresponding compounds and mass fractions in Table 1, and ultrasonically for more than 1 h to ensure that the components are evenly mixed. The obtained liquid crystal mixture was poured into a liquid crystal cell with a cell thickness of 10 μm for performance testing.

[0053] Compound type and mass percent and performance parameters in the nematic liquid crystal mixture of Table 1 Example 1

[0054]

[0055]

Embodiment 2

[0057] Prepare the nematic liquid crystal mixture according to the corresponding compounds and mass fractions in Table 2, and ultrasonically for more than 1 h to ensure that the components are mixed evenly. The obtained liquid crystal mixture was poured into a liquid crystal cell with a cell thickness of 10 μm for performance testing.

[0058] Compound species and mass percent and performance parameters in the nematic liquid crystal mixture of the second embodiment of table 2

[0059]

[0060]

Embodiment 3

[0062] Prepare the nematic liquid crystal mixture according to the corresponding compounds and mass fractions in Table 3, and ultrasonically for more than 1 h to ensure that the components are mixed evenly. The obtained liquid crystal mixture was poured into a liquid crystal cell with a cell thickness of 10 μm for performance testing.

[0063] Compound type and mass percent and performance parameters in the nematic liquid crystal mixture of the third embodiment of table 3

[0064]

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com