Iron-based vanadium-nitrogen microalloy additive and preparation method thereof

A micro-alloy additive, vanadium-nitrogen technology, applied in the field of iron-based vanadium-nitrogen microalloy additive and its preparation, can solve the problems of unstable nitriding quality, uneven nitriding, different reaction degrees, etc., and achieve stable composition, nitrogen The effect of uniform chemical and high vanadium-nitrogen ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An iron-based vanadium-nitrogen microalloy additive is characterized in that: by weight, 97.95 parts of 50% ferrovanadium, 2.00 parts of a combustion aid, and 0.05 parts of a nitriding catalyst.

[0028] Described 50 iron vanadiums are the iron vanadiums of FeV50-A or FeV50-B of the GB / T 4139-2004 iron vanadium standard, with an average particle diameter of 80-180 microns;

[0029] Said nitrogen is nitrogen with a purity greater than 99.99%;

[0030] The combustion aid is aluminum powder with a purity greater than 99% and a particle size of 150 microns;

[0031] The nitriding catalyst is titanium powder with a purity greater than 90% and a particle size of 150 microns.

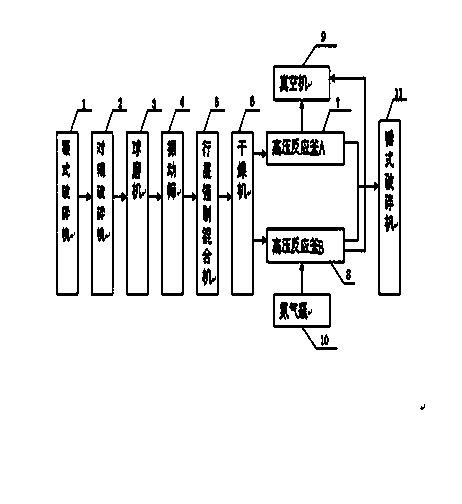

[0032] A preparation method for an iron-based vanadium-nitrogen microalloy additive comprises the following steps:

[0033] a. Put 50% ferrovanadium into the jaw crusher 1 for crushing, and crush it into particles smaller than or equal to 10 mm;

[0034] B. put the broken vanadium particles into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com