Building facade energy-saving system

An energy-saving system and facade technology, applied in the direction of building components, insulation, non-polymer adhesive additives, etc., can solve problems such as cracking of insulation boards and paint coatings, inconsistent thermal shock resistance, and reduced insulation effects, etc., to achieve Reduced weight, low density, and improved thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

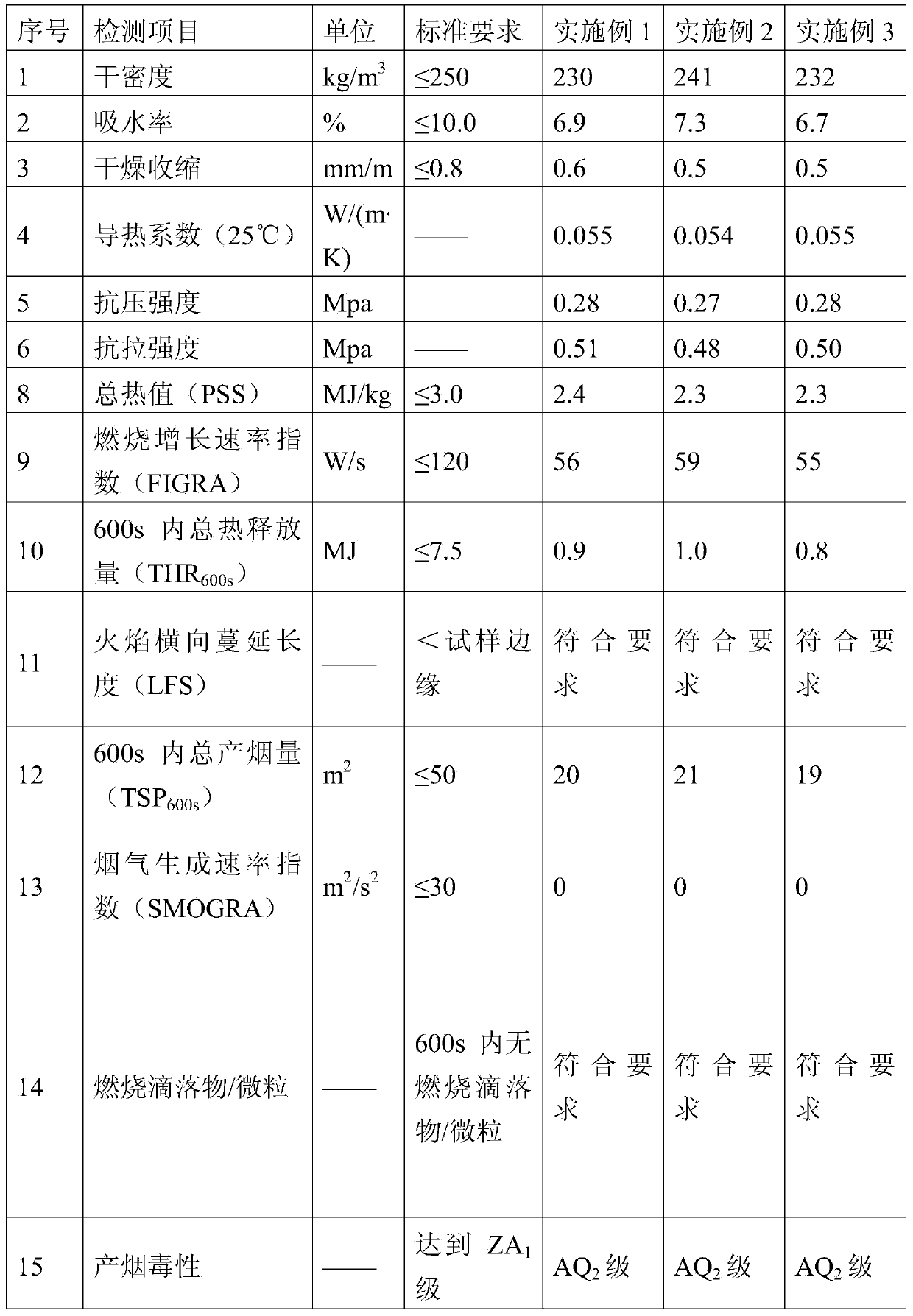

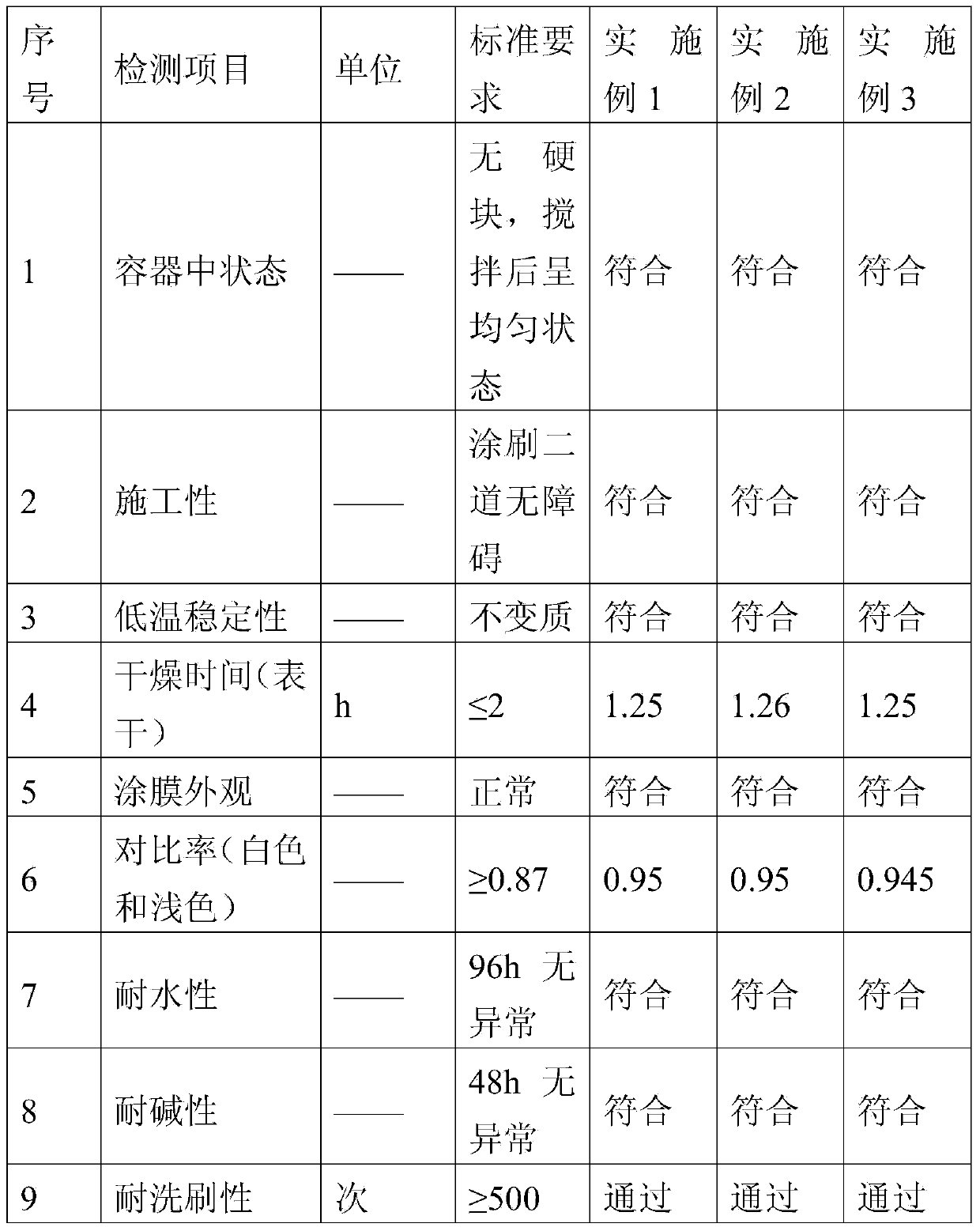

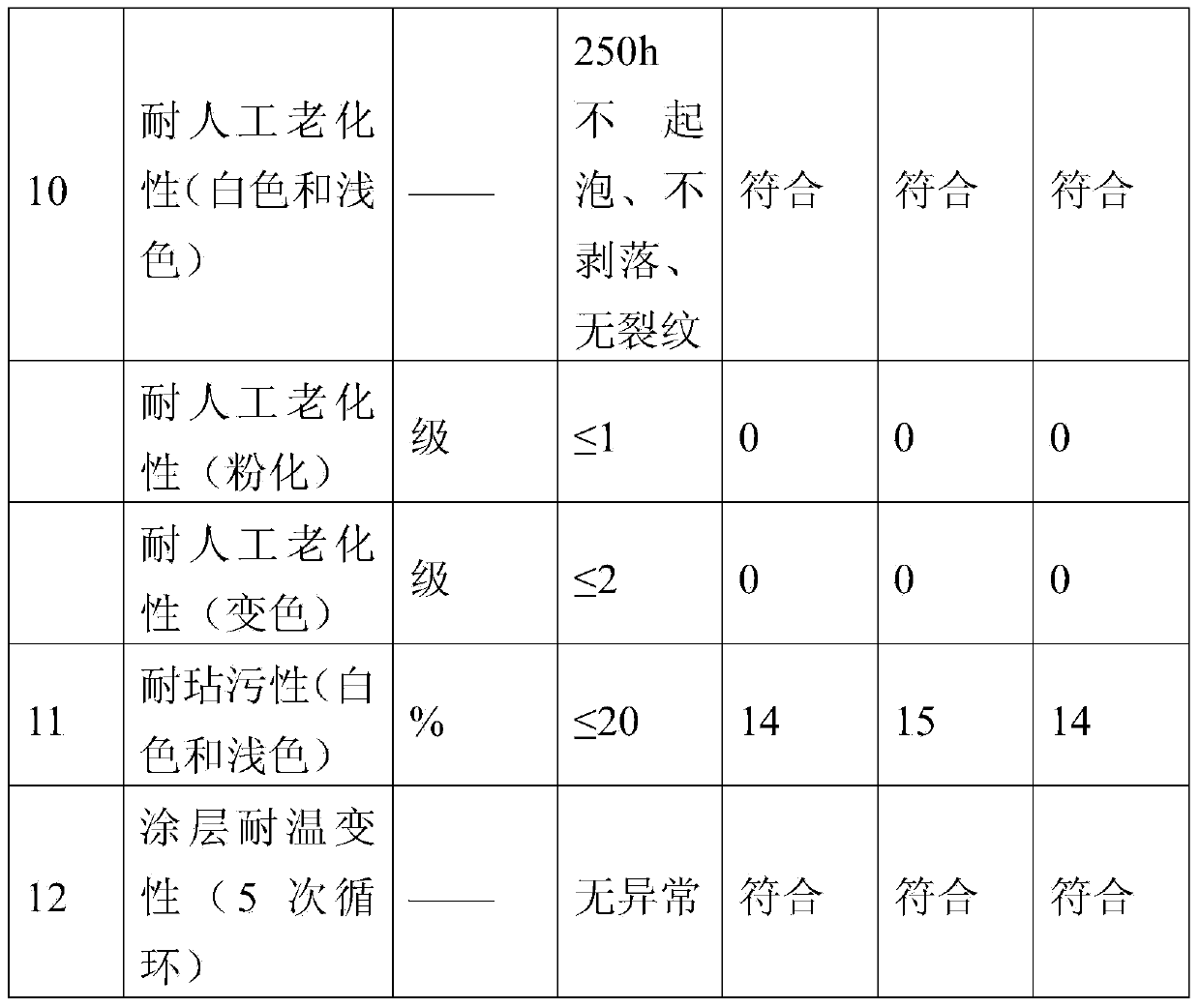

Examples

Embodiment 1

[0041] The building's facade energy-saving system consists of three parts. Firstly, the three parts are prepared separately:

[0042] (1) Insulation board: After mixing all raw materials, heat until the polyester resin is in a molten state. In this state, stir and mix the raw materials evenly, pour them into a mold, and cool. Described raw material and mass parts thereof are:

[0043] Polyester resin: 40 parts;

[0044] Expanded perlite: 6 parts;

[0045] Shell powder: average particle size ≤10μm, 10 parts;

[0046] Nut shell fine powder: average particle size ≤100μm, 7 parts;

[0047] Animal hair fiber: average length ≤0.1mm, 12 parts;

[0048] Straw fiber: average length ≤ 1mm, 12 parts;

[0049] Lime paste: 15 parts;

[0050] (2) Outer coating: After mixing all raw materials, stir and mix evenly. Described raw material and mass parts thereof are:

[0051] Animal hair fiber: average length ≤ 5μm, 1 part;

[0052] Straw fiber: average length ≤ 5μm, 1 part;

[0053] ...

Embodiment 2

[0067] The building's facade energy-saving system consists of three parts. Firstly, the three parts are prepared separately:

[0068] (1) Insulation board: After mixing all raw materials, heat until the polyester resin is in a molten state. In this state, stir and mix the raw materials evenly, pour them into a mold, and cool. Described raw material and mass parts thereof are:

[0069] Polyester resin: 48 parts;

[0070] Expanded perlite: 9 parts;

[0071] Shell powder: average particle size ≤10μm, 15 parts;

[0072] Nut shell fine powder: average particle size ≤100μm, 9 parts;

[0073] Animal hair fiber: average length ≤0.1mm, 15 parts;

[0074] Straw fiber: average length ≤ 1mm, 15 parts;

[0075] Lime paste: 18 parts;

[0076] (2) Outer coating: After mixing all raw materials, stir and mix evenly. Described raw material and mass parts thereof are:

[0077] Animal hair fiber: average length ≤ 5μm, 3 parts;

[0078] Straw fiber: average length ≤ 5 μm, 3 parts;

[0079]...

Embodiment 3

[0093] The building's facade energy-saving system consists of three parts. Firstly, the three parts are prepared separately:

[0094] (1) Insulation board: After mixing all raw materials, heat until the polyester resin is in a molten state. In this state, stir and mix the raw materials evenly, pour them into a mold, and cool. Described raw material and mass parts thereof are:

[0095] Polyester resin: 45 parts;

[0096] Expanded perlite: 7 parts;

[0097] Shell powder: average particle size ≤10μm, 12 parts;

[0098] Nut shell fine powder: average particle size ≤100μm, 8 parts;

[0099] Animal hair fiber: average length ≤0.1mm, 14 parts;

[0100] Straw fiber: average length ≤ 1mm, 14 parts;

[0101] Lime paste: 15-18 parts;

[0102] (2) Outer coating: After mixing all raw materials, stir and mix evenly. Described raw material and mass parts thereof are:

[0103] Animal hair fiber: average length ≤ 5μm, 2 parts;

[0104] Straw fiber: average length ≤ 5μm, 2 parts;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com