Gas-barrier film and process for producing same, and gas-barrier laminate

A technology of gas barrier and manufacturing method, applied in chemical instruments and methods, coatings, layered products, etc., to achieve the effects of low haze value, suppression of background reflection, and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] The preparation method of the silicon compound particles is not particularly limited, for example, the 2nd page 16th line to the 10th page 26th line of the International Publication Pamphlet WO95 / 17349 or the [0012] to [0031 of the Japanese Patent Laid-Open No. 6-16414 A ], specifically, by hydrolyzing and aging alkoxysilane, dissolving water glass, performing ion exchange, and concentrating. The calculation of the functional group ratio when using the former preparation method can be performed, for example, by the method described in the above-mentioned International Publication Pamphlet on page 15, line 19 to page 16, line 8, and when the latter preparation method is used, it can be estimated that 100 silanol groups mol %.

[0092] In general, for the use of alkoxysilane, it is known to apply a coating solution in which alkoxysilane or its hydrolyzate is mixed in resin to a film having an inorganic layer, but since alkoxysilane or its hydrolyzate The cohesion stress ...

Embodiment

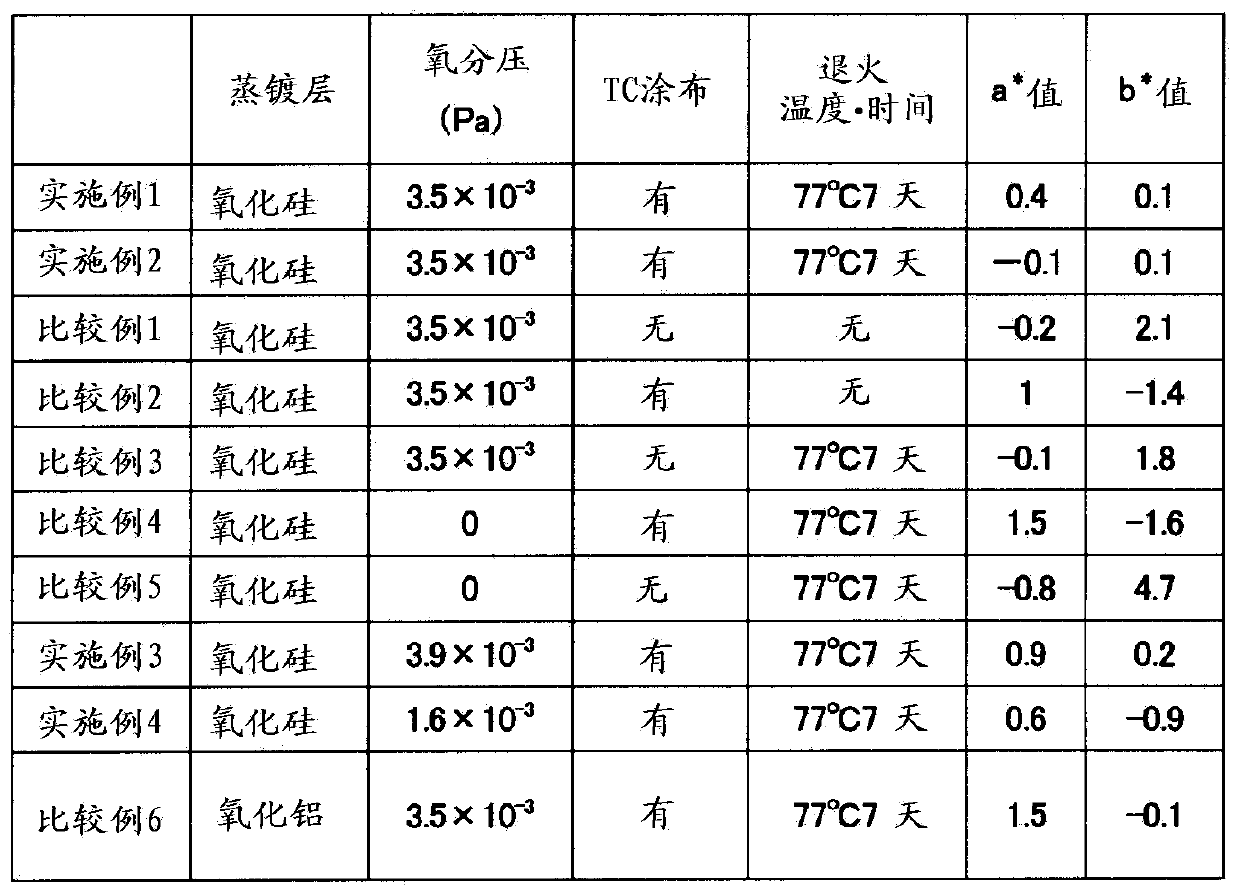

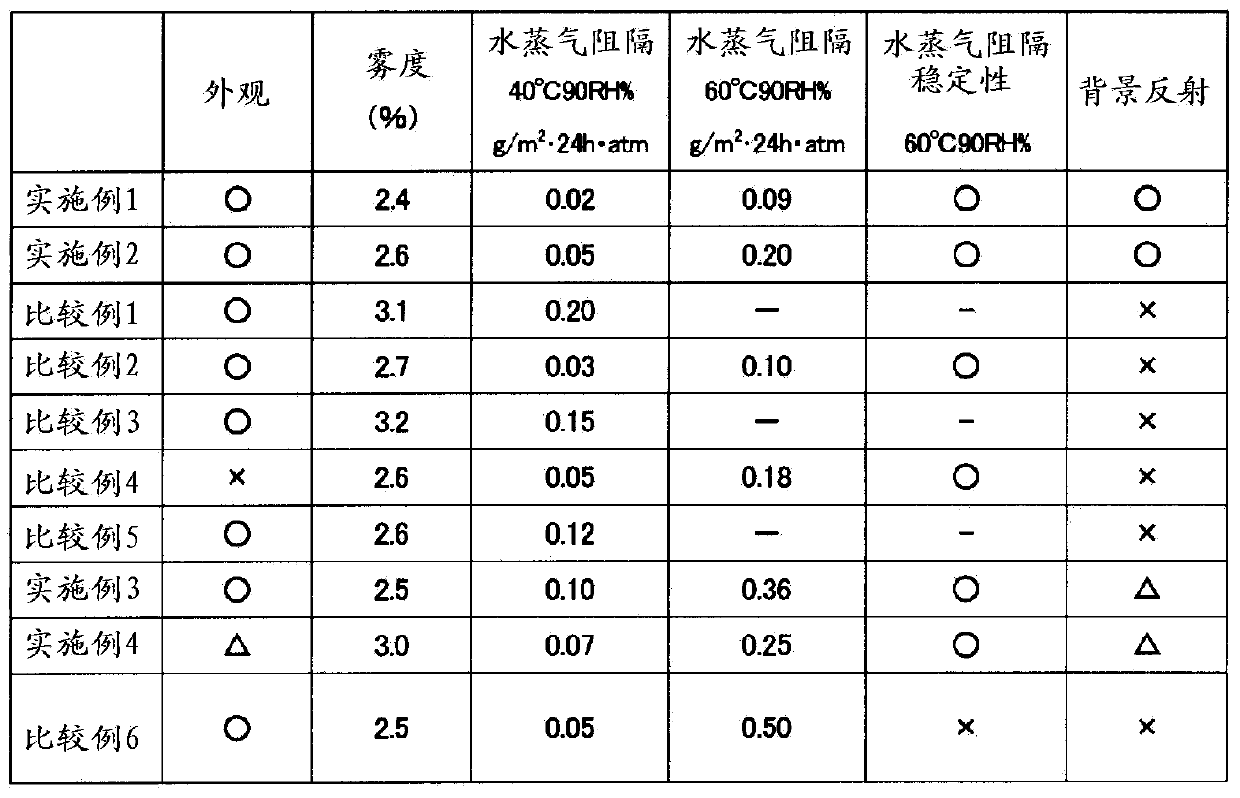

[0146] Next, the present invention will be described in further detail through examples, but the present invention is not limited by these examples.

[0147] The measurement methods of the properties of the gas barrier films and gas barrier laminates obtained in each example are shown below.

[0148]

[0149] Based on the conditions of JIS Z0222 "Moisture-proof packaging container test method for water vapor transmission" and JIS Z0208 "moisture-proof packaging material water vapor transmission test method", the following methods were used for evaluation.

[0150] Use 2 laminated films or laminates with a moisture permeable area of 10.0cm×10.0cm square, add about 20g of anhydrous calcium chloride as a moisture absorbent, make a bag with four sides sealed, and put the bag in a temperature of 40°C and a relative humidity In a 90% constant temperature and humidity device or a constant temperature and humidity device with a temperature of 60°C and a relative humidity of 90%, t...

preparation example 1

[0174] The preparation of preparation example 1 anchor coating agent

[0175] An isocyanate compound ("CORONATE L" manufactured by Nippon Polyurethane Industry Co., Ltd.) and a saturated polyester ("Vylon 300" manufactured by Toyobo Co., Ltd. with a number average molecular weight of 23,000) were mixed at a mass ratio of 1:1 to prepare an anchor coating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com