Technology and device for co-producing tight-peel citrus juice and mashed pulp

A technology of fruit juice and fruit puree, which is applied in the field of comprehensive utilization of citrus fruit juice and fruit puree, which can solve the problems of affecting the filtration effect of pectin liquid, the quality of pectin finished products, the obstacles of rinsing and filtration process, and the waste of fruit puree resources. Achieve the effects of increasing processing utilization, increasing product added value, and reducing waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

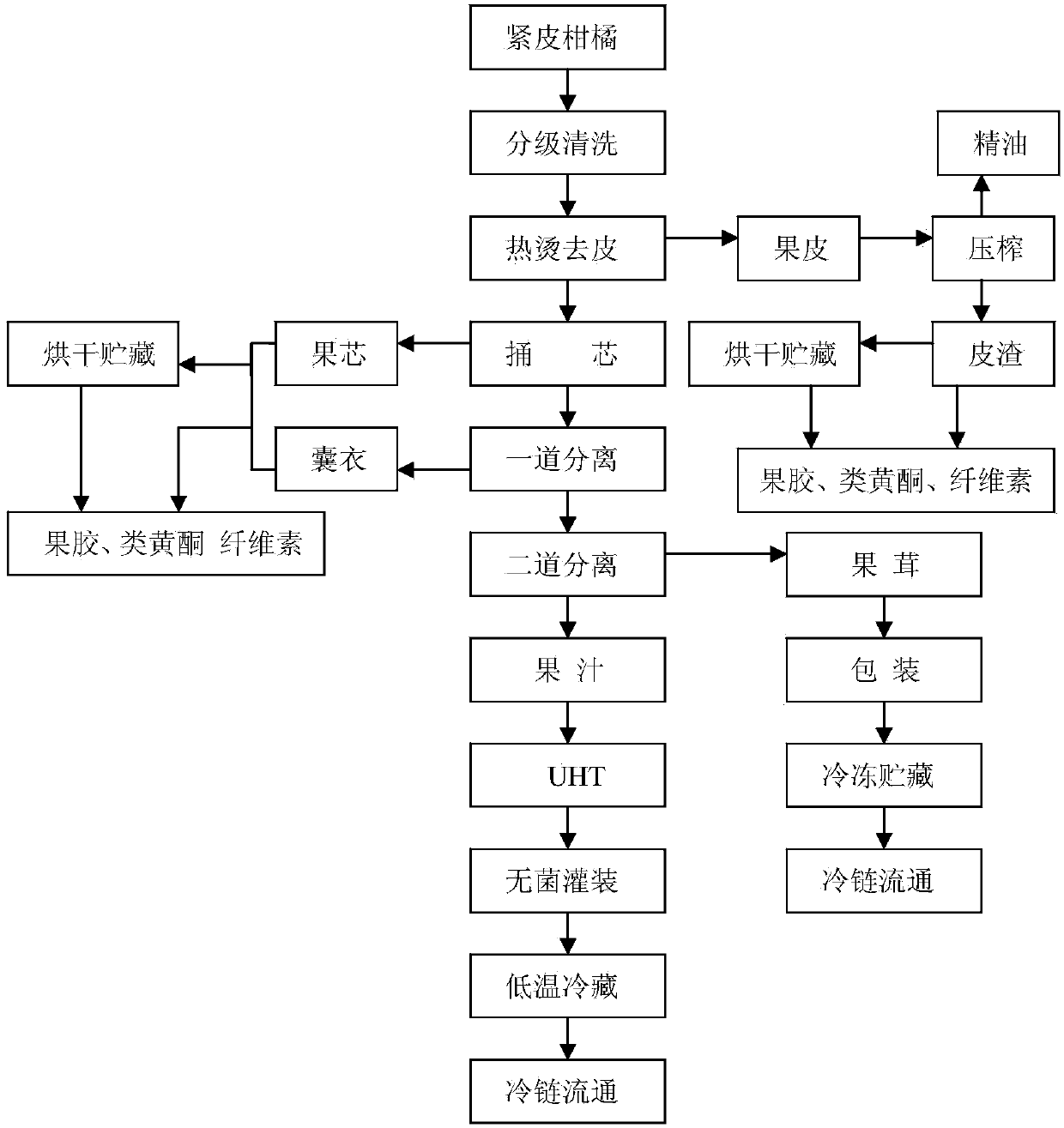

[0044] The co-production process 1 of citrus fruit juice and fruit puree comprises the following steps in sequence:

[0045] a) Take 1000kg of navel orange variety "Pengna" fruit, soak it in disinfectant water containing 0.2‰ available chlorine for 5 minutes, and then spray it once with clear water;

[0046] b) Blanch the cleaned fruit in hot water at 95°C for 1.5 minutes, and manually peel the fruit while it is still hot to obtain 245 kg of peel, which is used to extract essential oil, pectin, flavonoids and cellulose;

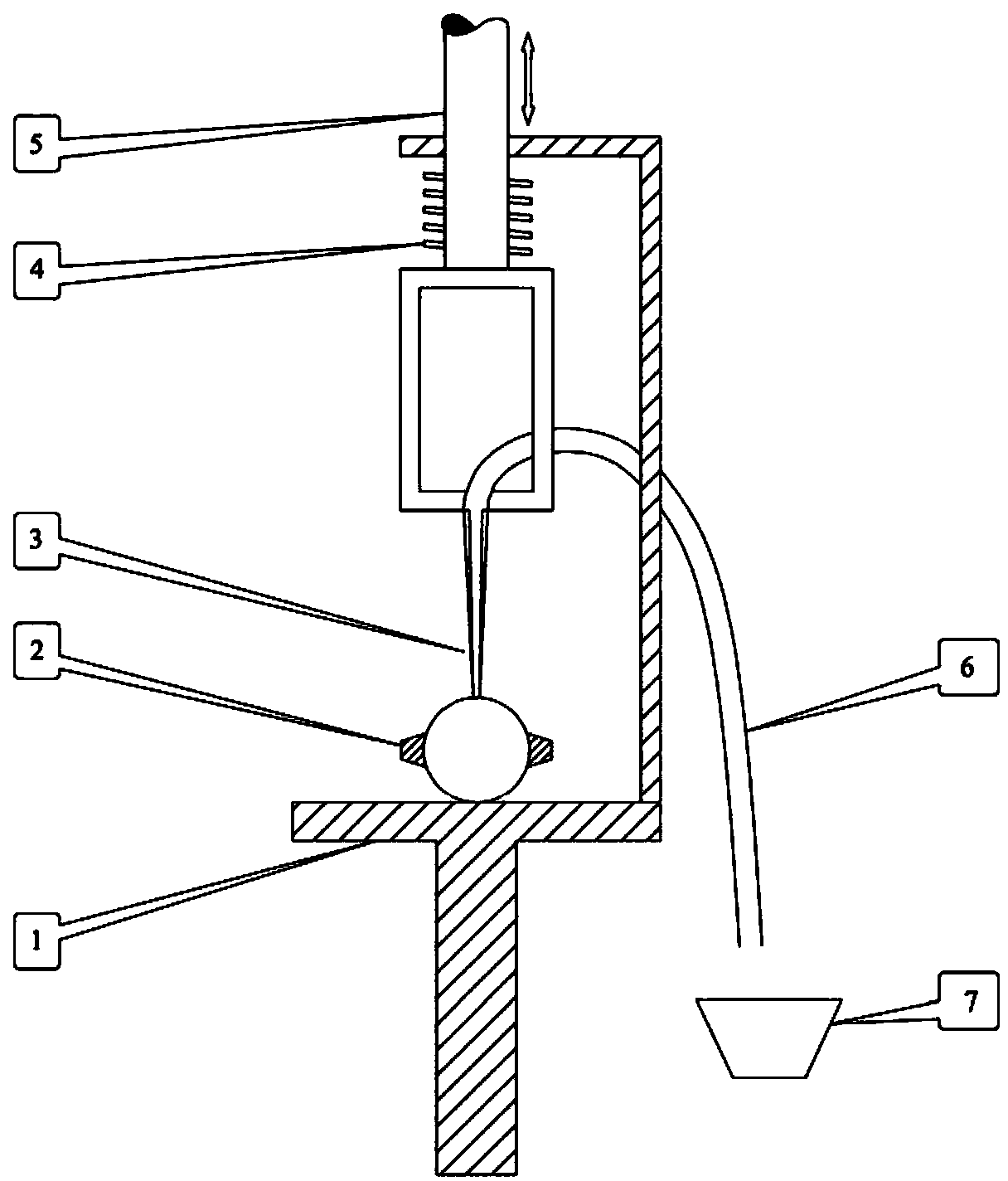

[0047] c) removing the core of the peeled fruit balls with a corer to obtain 53 kg of fruit cores for extracting pectin, flavonoids and cellulose;

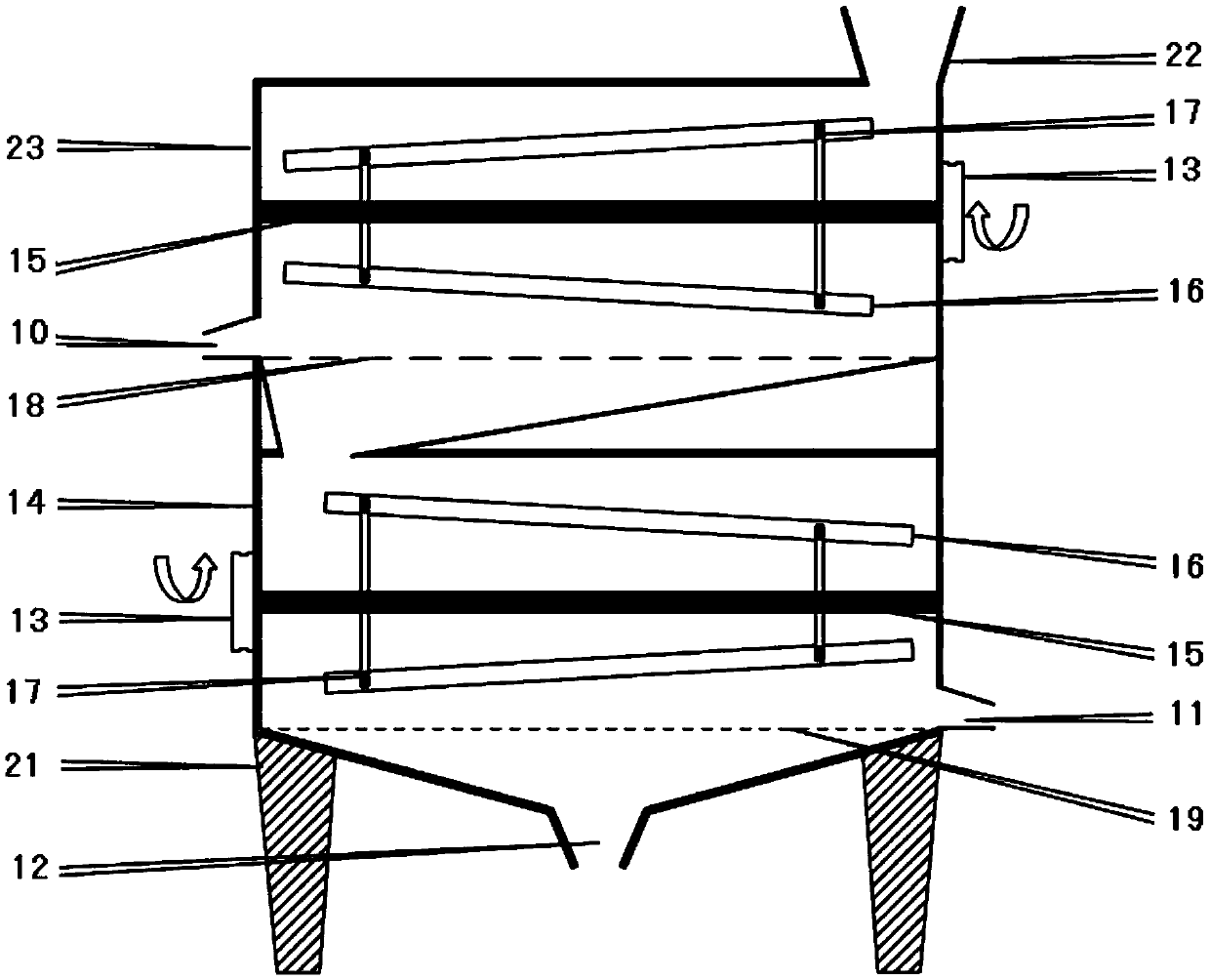

[0048] d) With the fruit balls after core removal, the fruit juice, fruit puree and capsule coating are separated by a secondary separator to obtain 525kg of fruit juice, 146kg of fruit pulp, and 31kg of rough capsule coating;

[0049] e) The fruit juice is sterilized at 110° C., 6S, rapidly cooled to 40° C., pa...

Embodiment 2

[0052] The co-production process 2 of tangerine juice and puree comprises the following steps in sequence:

[0053] a) Take 1000kg of lemon variety "Lisbon" fruit, soak it in disinfectant water containing 0.2‰ available chlorine for 5 minutes, and then spray it once with clear water;

[0054]b) Blanch the washed fruit in hot water at 95°C for 2 minutes, and manually peel the fruit while it is hot to obtain 251 kg of peel, which is used to extract essential oil, pectin, flavonoids and cellulose;

[0055] c) removing the core of the peeled fruit balls with a corer to obtain 56 kg of fruit cores for extracting pectin, flavonoids and cellulose;

[0056] d) With the fruit balls after core removal, the fruit juice, fruit puree and capsule coating are separated by a secondary separator to obtain 546kg of fruit juice, 102kg of fruit pulp, and 45kg of rough capsule coating;

[0057] e) The fruit juice is sterilized at 105° C., 4S, rapidly cooled to 40° C., packed in a 20 L aseptic bag...

Embodiment 3

[0060] The co-production process 3 of citrus fruit juice and fruit puree includes the following steps in sequence:

[0061] a) Take 1000kg of grapefruit variety "Maxu Seedless" fruit, soak it in disinfectant water containing 0.2‰ available chlorine for 5 minutes, and then spray it once with clear water;

[0062] b) Blanch the washed fruit in hot water at 98°C for 1 min, and manually peel the fruit while it is hot to obtain 232 kg of peel, which is used to extract essential oil, pectin, flavonoids and cellulose;

[0063] c) removing the core of the peeled fruit balls with a corer to obtain 48 kg of fruit cores for extracting pectin, flavonoids and cellulose;

[0064] d) The fruit balls after core removal are separated from fruit juice, fruit puree and capsule coating with a secondary separator to obtain 565kg of fruit juice, 112kg of fruit pulp, and 43kg of rough capsule coating;

[0065] e) The fruit juice is sterilized at 108° C., 4S, rapidly cooled to 40° C., packed in a 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com