Welding gun of high-energy tungsten electrode inert gas welding and process thereof

A tungsten inert gas, high-energy technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problem of low energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

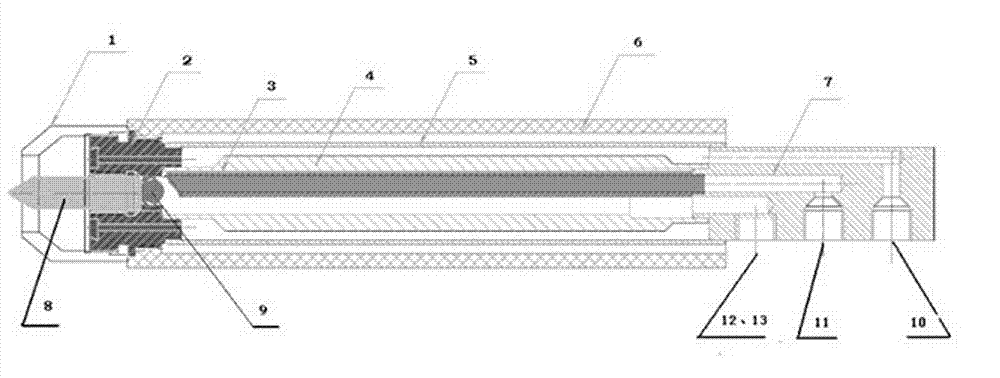

[0021] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a high-energy tungsten inert gas shielded welding torch, which includes an outer insulating tube 6, a tungsten pole seat 2 threadedly connected to one end of the outer insulating tube 6, and a ceramic nozzle 1 threadedly connected to the tungsten pole seat 2, A tungsten pole 8 is arranged inside the ceramic nozzle 1 , and the tungsten pole 8 is installed on the tungsten pole seat 2 , and the other end of the outer insulating tube 6 is connected to the joint end 7 . In the present embodiment, the tungsten pole 8 is processed with an external thread, and correspondingly, an internal thread is processed in the central hole of the tungsten pole seat.

[0022] The welding gun also has a cooling water system. The cooling water system includes a water channel. One end of the water channel is the water inlet 11 of the joint ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com