Composite board segmented explosive-distribution blast method

A composite board and drug distribution technology, applied in the direction of non-electric welding equipment, welding/welding/cutting items, manufacturing tools, etc., to achieve the effect of changing the overall bonding strength, high practical application value, and good layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of explosive method of composite plate subsection distributing explosives, such as Figure 4 shown, including the following steps:

[0038] 1) Base plate and cladding plate 5; the base plate is Q345R with a specification of 2460*5960*20mm; the cladding plate is TA10 (titanium) with a specification of 2500*6000*4mm. Both the base plate and the cladding plate are rectangular; the surface-treated base plate and the cladding plate are installed on the fort.

[0039] 2) Arranging the frame; installing a frame 6 for blocking explosives around the cladding plate; wherein the frame is made of wood or fiberboard.

[0040] 3) charge; such as Figure 4 As shown, the cladding plate 1 is divided into 5 regions symmetrically in the direction of the central axis with respect to the central axis in the length direction, and divided symmetrically on both sides into the central region-2 and the region-two symmetrical regions on both sides. Two (3a, 3b), two areas three (4a, 4b)...

Embodiment 2

[0046] The present invention also provides a method for exploding circular composite plates: as Figure 5 shown, including the following steps:

[0047] 1) Substrate and cladding plate 8; the substrate and cladding plate that have been surface-treated are installed on the fort, and the shape of the substrate and cladding plate is circular; the specification of the substrate is 4020 mm in diameter and 20 mm thick; the cladding plate is TA10 (titanium), The specification is 4000mm in diameter and 4mm in thickness.

[0048] 2) Arranging the frame; a frame 9 for blocking explosives is installed around the circumference of the cladding plate 8 .

[0049] 3) As shown in the figure, charges; the cladding plate is divided into a central circular area 10 along the circular direction, an annular area 11 surrounding the area 1, and an annular area extending from the enclosing area 2 to the boundary of the cladding plate The area three 12; the low detonation velocity explosive is loaded...

Embodiment 3

[0055] In the selection of the basic cladding plate, the substrate can also be other common alloy steel or carbon steel; the cladding plate can be one or more of aluminum, copper, titanium, zirconium, tantalum, niobium or stainless steel. Among them, if the cladding plate is rare metals such as zirconium, tantalum, and niobium, due to its high melting point, the two-layer plate is prone to disunity, and a thin buffer layer of titanium plate is added between the substrate and the cladding plate. The way of distributing explosives for explosive welding is as described in the above two embodiments and will not be repeated here.

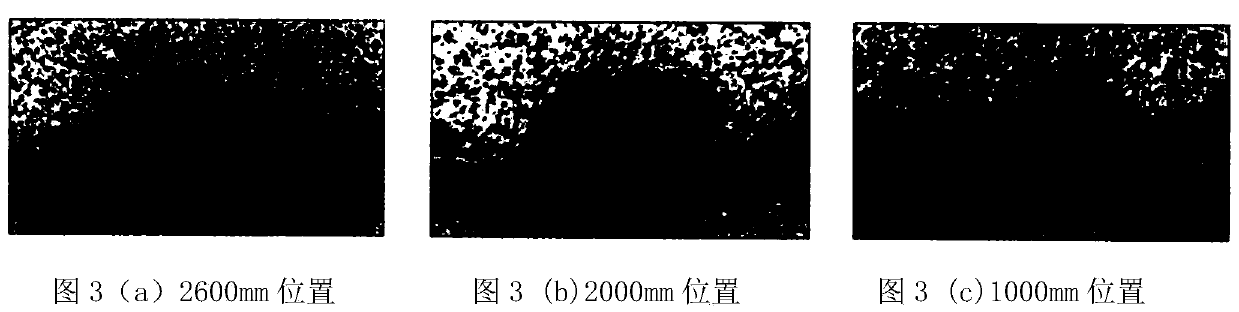

[0056] In order to compare the influence of the uniform charge distribution and segmented charge distribution methods on the combined interface wave, a pair of composite panels with the same size and different charge distribution methods were sampled for test analysis in the embodiment, and the samples were selected at the same position with the detonatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com