Heat-insulating coating material for firing enamel on surface of titanium alloy and preparation method thereof

A technology of thermal insulation coating and titanium alloy, which is applied in the field of firing enamel thermal insulation coating material and its preparation on the surface of titanium alloy, which can solve the problems of short service life of the coating and achieve good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

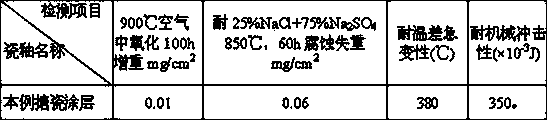

example 1

[0030] The chemical composition (by weight percentage) of the raw material formula of the titanium alloy enamel thermal insulation coating material is:

[0031] SiO 2 65

[0032] Al 2 o 3 2.0

[0033] B 2 o 3 4

[0034] CoO 1.5

[0035] TiO 2 4

[0036] CaO 2.3

[0037] NaNO 3 9

[0038] KMnO 4 2

[0039] ZrO 2 8

[0040] V 2 o 5 0.6

[0041] CaF 2 3.3

[0042] NiO 0.3.

[0043] After mixing the above raw materials, put them into the muffle furnace at 1350°C, heat preservation and melting at 1350°C for 4 hours, then discharge the material firstly through water quenching, and then air-dry in a hot air drying oven at 90°C for four hours to obtain a block-shaped enamel glaze .

[0044] Put the block enamel glaze into the ball mill, and add the following materials at the same time, the quality of the grinding material is compared with the enamel glaze: 5% clay, 0.5% bentonite, 8% cerium oxide, 3% yttr...

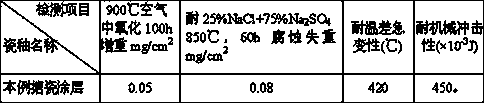

example 2

[0049] The chemical composition (by weight percentage) of the raw material formula of the titanium alloy enamel thermal insulation coating material is:

[0050] SiO 2 70

[0051] Al 2 o 3 2.0

[0052] B 2 o 3 3.0

[0053] CoO 1.0

[0054] TiO 2 5.0

[0055] CaO 2.0

[0056] NaNO 3 7.0

[0057] KMnO 4 2.9

[0058] ZrO 2 4.0

[0059] V2 o 5 0.5

[0060] CaF 2 2.0

[0061] NiO 0.6.

[0062] After mixing the above raw materials, put them into the muffle furnace at 1370°C, keep them warm at 1370°C for 4 hours, and then quench them with water, and then dry them in a hot air drying oven at 90°C for four hours to obtain a block-shaped enamel glaze. .

[0063] Put the block enamel glaze into the ball mill, and add the following materials at the same time, the quality of the grinding material is compared with the enamel glaze: 5% clay, 0.5% bentonite, 8% cerium oxide, 3% yttrium oxide, 0.5% sodium silicon fl...

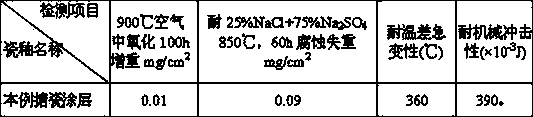

example 3

[0068] The chemical composition (by weight percentage) of the raw material formula of the titanium alloy enamel thermal insulation coating material is:

[0069] SiO 2 60

[0070] Al 2 o 3 2.5

[0071] B 2 o 3 5.0

[0072] CoO 2.0

[0073] TiO 2 6.0

[0074] CaO 3.0

[0075] NaNO 3 9.5

[0076] KMnO 4 4.0

[0077] ZrO 2 2.0

[0078] V 2 o 5 1.0

[0079] CaF 2 4.0

[0080] NiO 1.0.

[0081] After mixing the above raw materials, put them into the muffle furnace at 1370°C, keep them warm at 1370°C for 4 hours, and then quench them with water, and then dry them in a hot air drying oven at 90°C for four hours to obtain a block-shaped enamel glaze. .

[0082] Put the block enamel glaze into the ball mill, and add the following materials at the same time, the quality of the grinding material is compared with the enamel glaze: 5% clay, 0.5% bentonite, 8% cerium oxide, 3% yttrium oxide, 0.5% sodium silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com