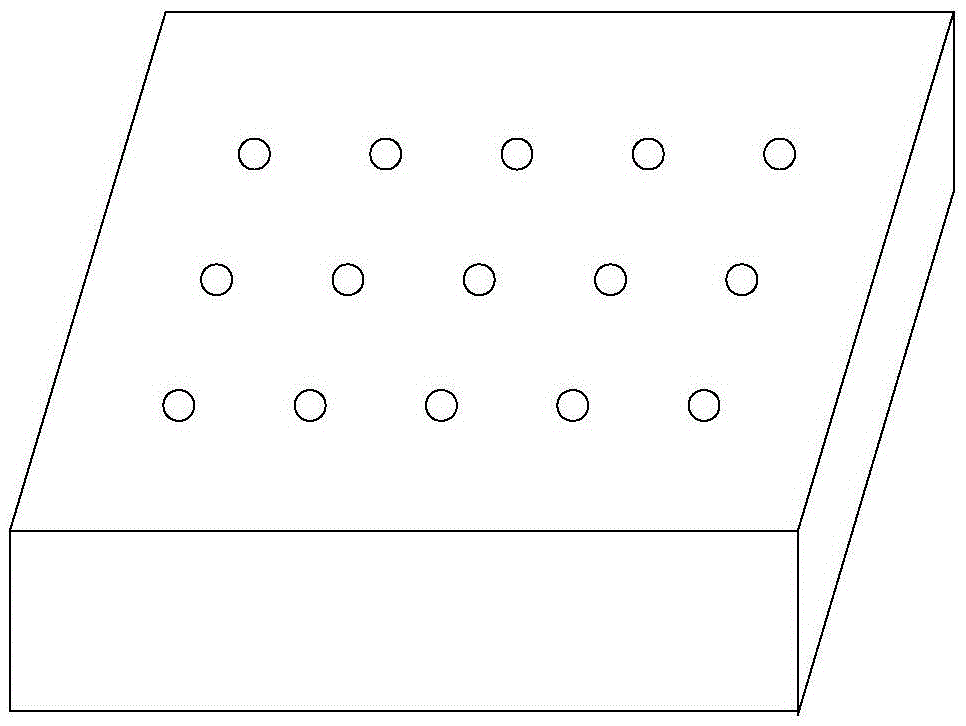

A water storage type industrial waste slag regenerated square brick and its preparation method

A technology for industrial waste residue and square brick, which is applied in the field of water storage type industrial waste residue recycling square brick and its preparation, can solve problems such as urban air drying and surface temperature, and achieve the advantages of improving the ecological circulation function of the road, increasing the air humidity and reducing the road runoff. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

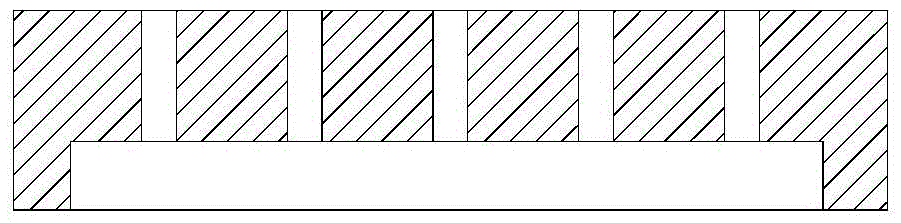

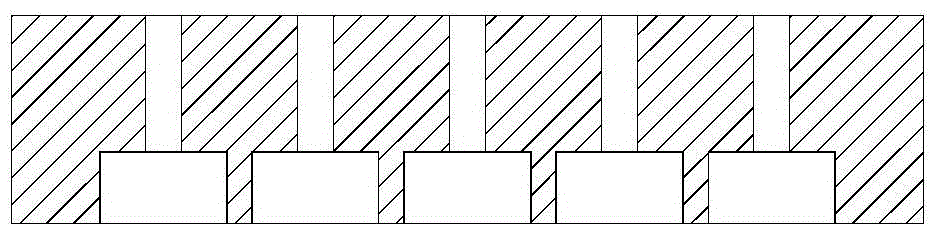

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the water storage type industrial waste slag regenerated square brick is made of main materials, water reducing agent, binder and tap water; wherein, the main materials are made of the following raw materials in mass percentage: desulfurized gypsum 61%, powder Coal ash 24%, silicon carbide slag 10%, quicklime 3%, cement 2%, wherein the mass percentage content of silicon carbide in the silicon carbide slag is 48%, the consumption of described tap water is 3 times of the main material quality, the described The consumption of water reducer is 0.05% of the sum of main ingredient and tap water quality, and the consumption of described binding agent is 0.02% of the sum of main ingredient and tap water quality; Described water reducer is preferably naphthalenesulfonic acid formaldehyde condensation product ( FDN) water reducing agent, the preferred mixture of sodium carboxymethylcellulose and redispersible latex powder mixed by mass ratio 1:1 of the binder....

Embodiment 2

[0046] In this embodiment, the water storage type industrial waste slag regenerated square brick is made of main material, water reducing agent, binder and tap water; wherein, the main material is made of the following raw materials in mass percentage: desulfurized gypsum 55%, powder Coal ash 28%, silicon carbide slag 13%, quicklime 3%, cement 1%, wherein the mass percentage content of silicon carbide in the silicon carbide slag is 48%, the consumption of described tap water is 2.5 times of the main material quality, the described The consumption of water reducer is 0.07% of the sum of main ingredient and tap water quality, and the consumption of described binding agent is 0.01% of the sum of main ingredient and tap water quality; Described water reducer is preferably naphthalenesulfonic acid formaldehyde condensation product ( FDN) water reducing agent, the preferred mixture of sodium carboxymethyl cellulose and redispersible latex powder mixed by mass ratio 3:1 of the binder....

Embodiment 3

[0053] In this embodiment, the water storage type industrial waste slag regenerated square brick is made of main material, water reducer, binder and tap water; wherein, the main material is made of the following raw materials in mass percentage: desulfurized gypsum 60%, powder Coal ash 20%, silicon carbide slag 13%, quicklime 5%, cement 2%, wherein the mass percentage content of silicon carbide in the silicon carbide slag is 45%, the consumption of described tap water is 3 times of main material quality, described The consumption of water reducer is 0.04% of the sum of main ingredient and tap water quality, and the consumption of described binding agent is 0.02% of the sum of main ingredient and tap water quality; Described water reducer is preferably naphthalenesulfonic acid formaldehyde condensation product ( FDN) water reducing agent, the preferred mixture of sodium carboxymethyl cellulose and redispersible latex powder mixed in a mass ratio of 2:1 as the binder.

[0054] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com