Novel negative thermal expansion material Sm1-xSrxMnO3-sigma

A negative thermal expansion material, a new type of technology, applied in the field of inorganic non-metallic materials, can solve the problem of few materials, and achieve the effect of simple method, good scope of application, and good adaptability to popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

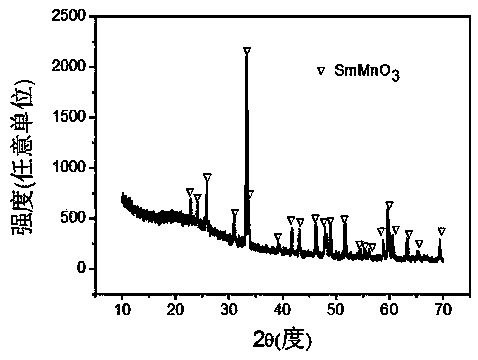

Embodiment 1

[0028] The new negative thermal expansion material Sm prepared in this embodiment 1-x Sr x MnO 3-σ , In Sm 2 O 3 , SrO, Mn 2 O 3 As a raw material, it is prepared by solid-phase synthesis, which specifically includes the following steps:

[0029] (1) Weigh the raw materials with the molar ratio Sm:Sr:Mn=(1-x):x:1, where x=0, that is, the raw materials used in this embodiment only include Sm 2 O 3 , Mn 2 O 3 , The molar ratio of the two is 1:1; mix and grind the raw materials for 0.5h, in order to make the mixing uniform, add an appropriate amount of absolute ethanol and continue to grind for 0.5h, then dry at 353K for 30min, continue to grind for a few minutes to mix the raw materials Evenly

[0030] (2) tableting the mixture in step (1); the tableting is compressed by a uniaxial tablet press at a pressure of 200 MPa for 2 to 3 minutes to form a cylindrical embryo with a diameter of 10 mm and a height of about 5 mm;

[0031] (3) Put the material after pressing in step (2) into a box ...

Embodiment 2

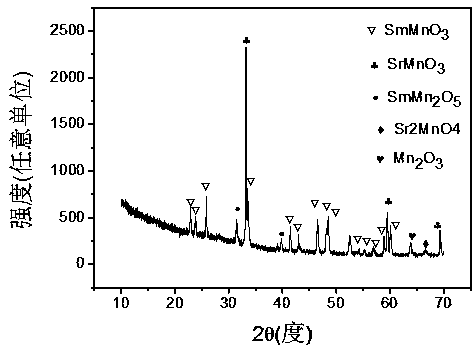

[0034] The steps of preparing the negative thermal expansion material in this embodiment are the same as in embodiment 1, only adjusting x=0.1, and adjusting the sintering parameters as follows: heat preservation at 1273K for 10 hours, and then continue to heat up to 1723K for sintering and heat preservation for 24 hours.

[0035] Prepared negative thermal expansion material Sm 0.9 Sr 0.1 MnO 2.95 The XRD spectrum phase analysis is as figure 2 . Analysis shows that the product mainly contains SmMnO 3 Phase (PDF No. 00-025-0747), SrMnO 3 Phase (PDF number 00-023-1413) and SmMn 2 O 5 (PDF number is 00-052-1096), Sr 2 MnO 4 Phase (PDF number is 01-089-4543), Mn 2 O 3 Phase (PDF number is 01-073-1826).

Embodiment 3

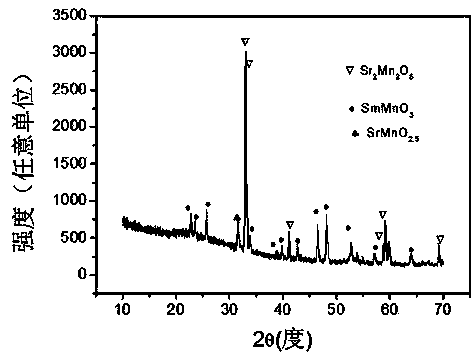

[0037] The steps for preparing the negative thermal expansion material in this embodiment are the same as in embodiment 1, only adjusting x=0.15, and adjusting the sintering parameters as follows: heat preservation at 1273K for 24h, then continue to heat up to 1623K for sintering and heat preservation for 24h.

[0038] Prepared negative thermal expansion material Sm 0.85 Sr 0.15 MnO 2.925 The XRD spectrum phase analysis is as image 3 . Analysis shows that the product mainly contains Sr 2 MnO 5 Phase (PDF number 01-070-3790), SmMnO 3 Phase (PDF number 00-025-0747) and SrMnO 2 . 5 (PDF number is 00-028-1232).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com