Method for preparing furan resin for cast iron with waste water and solid formaldehyde

A technology of solid formaldehyde and furan resin, which is applied in the processing field of cast iron resin, can solve environmental pollution and other problems, achieve the effects of reducing production costs, good collapsibility, and reducing the workload of sand cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

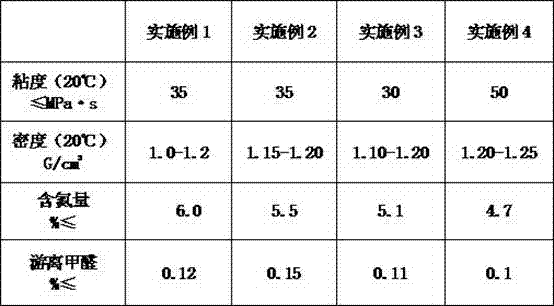

Examples

Embodiment 1

[0031] It is made from 740kg of furfuryl alcohol, 30kg of solid formaldehyde, 130kg of urea, 2kg of γ-methacryloxypropyl trimethoxysilane and 100kg of waste water through the following steps:

[0032] (1) Add waste water and furfuryl alcohol into the reaction kettle, start the mixer to stir, and adjust the pH value to 8.5-9.5 with sodium hydroxide;

[0033] (2) Add urea and solid formaldehyde, add steam to raise the temperature, keep raising the temperature by 8°C every 5 minutes, raise the temperature to 100-110°C, and keep it warm for 140 minutes;

[0034] (3) Cool down to 50°C, add furfuryl alcohol and γ-methacryloxypropyltrimethoxysilane, stir evenly, and discharge to obtain the finished product;

[0035] The above-mentioned solid formaldehyde is paraformaldehyde with a low degree of polymerization, and the content is 90.0%.

[0036] The mass percentage of furfuryl alcohol added in the above step (1) is 70% of the formula composition, and the amount of furfuryl alcohol ad...

Embodiment 2

[0038] It is made from 760kg of furfuryl alcohol, 20kg of solid formaldehyde, 120kg of urea, 2kg of silane coupling agent and 100kg of waste water through the following steps:

[0039](1) Add waste water and furfuryl alcohol into the reaction kettle, start the mixer to stir, and adjust the pH value to 8.5-9.5 with sodium hydroxide;

[0040] (2) Add urea and solid formaldehyde, add steam to raise the temperature, keep raising the temperature by 8°C every 5 minutes, raise the temperature to 100-110°C, and keep it warm for 150 minutes;

[0041] (3) Cool down to 50°C, add furfuryl alcohol and coupling agent, stir evenly, then discharge to obtain finished product;

[0042] The above-mentioned solid formaldehyde is paraformaldehyde with a low degree of polymerization, and its content is 96.0%.

[0043] The mass percentage of furfuryl alcohol added in the above step (1) is 75% of the formula composition, and the amount of furfuryl alcohol added in the step (3) is the rest of the fur...

Embodiment 3

[0045] It is made from 780kg of furfuryl alcohol, 30kg of solid formaldehyde, 110kg of urea, 3kg of silane coupling agent and 80kg of waste water through the following steps:

[0046] (1) Add wastewater and furfuryl alcohol into the reaction kettle, start the mixer to stir, and adjust the pH value to 8.5-9.5 with potassium hydroxide;

[0047] (2) Add urea and solid formaldehyde, add steam to raise the temperature, keep raising the temperature by 8°C every 5 minutes, raise the temperature to 100-110°C, and keep it warm for 155 minutes;

[0048] (3) Cool down to 50°C, add furfuryl alcohol and coupling agent, stir evenly, then discharge to obtain finished product;

[0049] The above-mentioned solid formaldehyde is paraformaldehyde with a low degree of polymerization, and its content is 93.0%.

[0050] The mass percentage of furfuryl alcohol added in the above step (1) is 78% of the formula composition, and the amount of furfuryl alcohol added in the step (3) is the remaining par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com