Waterborne polyurethane resin and application thereof in waterborne micropore coating leather of split leather

A technology of water-based polyurethane and split skin, applied in the chemical industry, can solve problems such as poor appearance, achieve good hand feeling, reduce costs, and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

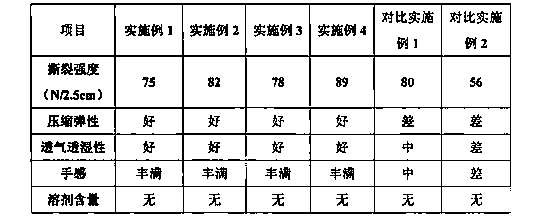

Examples

Embodiment 1

[0029] A split leather with a thickness of 2 mm made of cowhide is coated with water-based polyurethane adhesive resin by roller coating to form an adhesive layer. 100 parts of water-based anionic polyurethane slurry (the company's FU-2315 is selected, and the 100% tensile strength of the dry film is 30kg / cm 3 , with a solid content of 40%), 3 parts of sodium sulfosuccinate, 3 parts of ammonium stearate, 2 parts of polyisocyanate crosslinking agent, 1 part of polyurethane associative thickener PU40W, stir for 1 hour with a high-speed mixer, and mix well , to obtain a foamed resin. The foamed material was applied to the treated split skin by roller coating to a wet thickness of 0.5 mm. After being dried in a drying oven, the split leather is obtained.

Embodiment 2

[0031] A split leather with a thickness of 1.8 mm made of cowhide is coated with water-based polyurethane adhesive resin by roller coating to form an adhesive layer. 100 parts of water-based anionic polyurethane slurry (the company's FU-2305 is selected, and the 100% tensile strength of the dry film is 50kg / cm 3 , with a solid content of 42%), 2 parts of sodium sulfosuccinate, 4 parts of ammonium stearate, 6 parts of melamine-formaldehyde resin, 1.2 parts of polyurethane associative thickener PU40W, stir with a high-speed mixer for 1.5h, fully Mix well to obtain a foamed resin. The foamed material was applied to the treated split skin by roller coating to a wet thickness of 0.7 mm. After being dried in a drying oven, the split leather is obtained.

Embodiment 3

[0033] A split skin made of pigskin with a thickness of 3 mm is coated with water-based polyurethane adhesive resin by roller coating to obtain an adhesive layer. 100 parts of water-based anionic polyurethane slurry (the company's FU-2305 is selected, and the 100% tensile strength of the dry film is 50kg / cm 3 , with a solid content of 42%), 4 parts of sodium sulfosuccinate, 3 parts of ammonium stearate, 3 parts of polyisocyanate cross-linking agent, 1.5 parts of polyurethane associative thickener PU40W, stir with a high-speed mixer for 1 hour, fully Mix well to obtain a foamed resin. The foamed material was applied to the treated split skin by roller coating to a wet thickness of 0.6 mm. After being dried in a drying oven, the split leather is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com